Supply chain risk assessment is crucial for modern businesses. It’s not just about identifying potential problems, but proactively mitigating them. This guide provides a comprehensive overview, from defining the process to implementing effective mitigation strategies and monitoring their success.

Understanding the various risks facing your supply chain, from geopolitical events to supplier vulnerabilities, is essential. A robust assessment process allows you to anticipate disruptions, prioritize potential problems, and ultimately build a more resilient and adaptable supply chain.

Introduction to Supply Chain Risk Assessment

Supply chain risk assessment is a crucial process for modern businesses. It’s not just about identifying potential problems; it’s about proactively planning for and mitigating those risks. In today’s interconnected global marketplace, disruptions can quickly cascade through a company’s operations, impacting everything from production and delivery to customer satisfaction and financial performance. A well-executed assessment is essential for building resilience and ensuring long-term success.Understanding and managing risks throughout the supply chain is paramount to maintaining profitability and operational efficiency.

It’s no longer sufficient to simply react to problems as they arise. A proactive approach, driven by thorough risk assessment, allows businesses to anticipate potential disruptions, implement preventive measures, and minimize the negative impact of unexpected events. This proactive stance is critical in today’s volatile and unpredictable business environment.

Defining Supply Chain Risk Assessment

Supply chain risk assessment is a systematic evaluation of potential threats and vulnerabilities within a company’s supply chain. It involves identifying, analyzing, and prioritizing risks to determine their potential impact on the business. This process goes beyond simply listing potential problems; it aims to understand the likelihood and consequences of each risk.

Importance of Supply Chain Risk Assessment

Supply chain risk assessment is vital for modern business operations for several reasons. Firstly, it enables businesses to anticipate and prepare for disruptions, preventing significant financial losses and operational hiccups. Secondly, it facilitates proactive risk mitigation strategies, allowing companies to implement preventative measures to lessen the severity of potential incidents. Finally, a robust risk assessment process enhances business resilience by fostering a culture of preparedness and adaptability.

Key Objectives of a Robust Supply Chain Risk Assessment Process

A comprehensive supply chain risk assessment should have several key objectives. These include identifying potential disruptions, assessing the potential impact of these disruptions, and developing strategies to mitigate the identified risks. Prioritizing risks based on their likelihood and potential impact is also critical to focus resources effectively. Ultimately, a successful assessment aims to enhance the resilience and adaptability of the supply chain.

Types of Supply Chain Risks

Understanding the various types of risks that can affect a supply chain is essential for a comprehensive assessment. This allows businesses to tailor mitigation strategies to specific vulnerabilities. The following table Artikels common supply chain risks, their potential impact, and possible mitigation strategies.

| Type of Risk | Description | Potential Impact | Mitigation Strategies |

|---|---|---|---|

| Geopolitical Instability | Political conflicts, trade wars, sanctions, or other global events disrupting trade and logistics. | Disrupted shipments, increased costs, lost revenue, reputational damage. | Diversifying suppliers, establishing contingency plans, building relationships with local authorities, hedging against currency fluctuations. |

| Natural Disasters | Events like earthquakes, floods, hurricanes, or wildfires impacting infrastructure and supply lines. | Production halts, supply chain disruptions, damage to facilities, and increased costs. | Identifying alternative routes, building resilient infrastructure, establishing emergency response plans, and securing insurance coverage. |

| Supply Shortages | Unforeseen scarcity of raw materials, components, or finished goods. | Production delays, lost sales, increased costs, and potential reputational damage. | Maintaining sufficient inventory levels, diversifying suppliers, negotiating long-term contracts, and implementing alternative sourcing strategies. |

| Cybersecurity Threats | Attacks on IT systems, data breaches, or disruptions to digital communication systems. | Data breaches, production downtime, loss of confidential information, financial losses. | Implementing robust cybersecurity measures, investing in data encryption, developing incident response plans, and conducting regular security audits. |

| Transportation Issues | Delays, disruptions, or disruptions to transportation networks, including logistics bottlenecks, strikes, and infrastructure failures. | Late deliveries, increased costs, lost sales, and customer dissatisfaction. | Diversifying transportation modes, optimizing routes, establishing backup transportation options, and fostering strong relationships with logistics providers. |

Identifying Supply Chain Vulnerabilities

Unraveling the intricate web of a global supply chain reveals a tapestry of potential weaknesses. Understanding these vulnerabilities is crucial for businesses to proactively mitigate risks and ensure resilience. This section delves into the various stages of the supply chain, exploring common pitfalls and the methods for detecting potential disruptions.Identifying weak points isn’t just about spotting problems; it’s about anticipating them.

By understanding the factors contributing to vulnerabilities, businesses can build more robust and adaptable supply chains. This proactive approach allows companies to respond effectively to unforeseen events and maintain smooth operations.

Common Vulnerabilities Across Supply Chain Stages

Understanding the vulnerabilities at each stage of the supply chain is essential for comprehensive risk assessment. Issues in sourcing, manufacturing, transportation, and distribution can all create cascading effects, impacting the entire network.

- Sourcing: Over-reliance on a single supplier can create a bottleneck. If that supplier faces disruption, the entire chain can be affected. Similarly, a lack of diverse sourcing options leaves the chain exposed to market fluctuations and geopolitical instability.

- Manufacturing: Natural disasters, labor disputes, or even changes in government regulations can halt production. A lack of contingency plans or redundant manufacturing facilities makes the chain susceptible to these disruptions.

- Transportation: Geopolitical tensions, port congestion, or unexpected weather events can severely disrupt transportation networks. This can lead to delays, shortages, and significant financial losses.

- Distribution: Inadequate warehousing capacity, inefficient logistics, or issues with final-mile delivery can hinder the timely delivery of goods. A lack of flexibility in distribution networks can make it difficult to adapt to changing market demands.

Methods for Identifying Potential Disruptions in a Global Supply Chain

Proactive identification of potential disruptions is key to effective risk management. Several methods can be employed to analyze global supply chains and identify weak points.

- Scenario Planning: Creating various hypothetical scenarios, such as natural disasters, political instability, or pandemics, allows businesses to anticipate potential disruptions and develop contingency plans.

- Supplier Relationship Management: Maintaining open communication and regular dialogue with suppliers helps businesses understand their potential risks and develop mitigation strategies.

- Data Analytics: Utilizing data from various sources, including weather patterns, economic indicators, and social unrest, allows businesses to identify potential disruptions early on.

- Industry Benchmarking: Comparing best practices and identifying common risks across industries allows businesses to learn from others’ experiences and avoid potential pitfalls.

Factors Contributing to Supply Chain Vulnerabilities

Several factors can contribute to the vulnerability of a supply chain. Understanding these factors is critical for developing effective risk mitigation strategies.

- Over-reliance on single suppliers: This creates a bottleneck, making the supply chain extremely susceptible to disruptions.

- Lack of diversification in sourcing: A limited number of suppliers makes the supply chain dependent on a single market, leading to vulnerabilities during economic downturns or natural disasters.

- Geopolitical instability: Political conflicts, trade wars, or sanctions can severely disrupt supply chains, leading to significant delays and cost increases.

- Natural disasters: Hurricanes, earthquakes, floods, and other natural disasters can cause disruptions in transportation, manufacturing, and other supply chain activities.

- Economic downturns: Recessions, inflation, and currency fluctuations can impact the demand for products, causing disruptions in production and distribution.

Identifying Weak Points in Supplier Relationships

Strengthening supplier relationships is crucial for mitigating risks. A thorough assessment of supplier capabilities and vulnerabilities is essential.

- Supplier Due Diligence: Evaluating suppliers’ financial stability, operational capabilities, and compliance with regulations is essential for identifying potential risks.

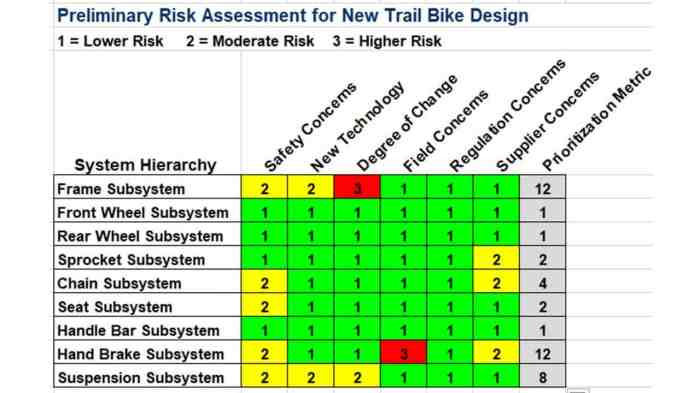

- Risk Assessment Matrices: Developing a structured framework for evaluating suppliers’ risks based on various criteria allows businesses to prioritize and address vulnerabilities effectively.

- Regular Communication: Maintaining open communication channels with suppliers fosters a collaborative environment, enabling businesses to understand and address potential issues promptly.

Technology’s Role in Identifying Emerging Risks, Supply chain risk assessment

Technology plays a significant role in anticipating and managing supply chain risks. Advanced technologies can monitor potential disruptions and provide early warnings.

- Predictive Analytics: Using historical data and current trends, predictive analytics can identify potential disruptions and assess their impact on the supply chain.

- Real-time Tracking: Advanced tracking technologies can monitor the movement of goods in real time, providing insights into potential delays and disruptions.

- Data Visualization Tools: Visualizing data from various sources allows businesses to gain a comprehensive understanding of the supply chain’s vulnerabilities and identify potential disruptions quickly.

Examples of Geopolitical Events Creating Vulnerabilities

Geopolitical events can create significant vulnerabilities in global supply chains. These events can disrupt trade, cause shortages, and impact production.

- Trade Wars: Trade disputes and tariffs can disrupt supply chains by increasing costs and creating uncertainties for businesses.

- Political Instability: Political conflicts and social unrest in certain regions can lead to disruptions in transportation and manufacturing.

- Sanctions: International sanctions can restrict access to certain materials or suppliers, leading to shortages and supply chain disruptions.

Categories of Supply Chain Risks

A comprehensive risk assessment should categorize risks to facilitate effective mitigation strategies.

| Category | Description | Examples | Mitigation Strategies |

|---|---|---|---|

| Political | Risks associated with political instability, conflicts, or government policies. | Trade wars, sanctions, political unrest, changes in trade regulations | Diversifying sourcing, building relationships with multiple suppliers, developing contingency plans |

| Environmental | Risks associated with natural disasters, climate change, or environmental regulations. | Floods, earthquakes, droughts, extreme weather events, environmental regulations | Developing resilient infrastructure, implementing disaster recovery plans, using sustainable materials |

| Economic | Risks associated with economic fluctuations, currency exchange rates, or market conditions. | Recessions, inflation, currency fluctuations, changes in consumer demand | Developing financial buffers, diversifying markets, hedging against currency fluctuations |

| Social | Risks associated with labor shortages, social unrest, or changes in consumer preferences. | Labor strikes, social unrest, changes in consumer demand, supply chain disruptions | Developing relationships with diverse suppliers, building resilient labor practices, adapting to changing consumer preferences |

Assessing Risk Impact and Likelihood

Understanding the potential impact and likelihood of risks is crucial for effective supply chain management. A thorough risk assessment helps prioritize mitigation efforts, ensuring resources are allocated strategically. This involves quantifying the potential harm and probability of each risk event, allowing for a more nuanced and proactive approach to supply chain security.Risk assessment matrices provide a structured framework for visualizing and analyzing the interplay between the impact and likelihood of potential disruptions.

By understanding the potential consequences and the probability of their occurrence, companies can develop tailored strategies to address these risks effectively.

Risk Assessment Matrices

Risk assessment matrices are tools that visually represent the relationship between the impact and likelihood of potential risks. These matrices help in prioritizing risks based on their potential severity. A common approach uses a qualitative or quantitative scale to categorize impact and likelihood, then combines these ratings to assign a risk score. This scoring system enables a clear understanding of the relative importance of each risk and facilitates focused mitigation strategies.

Quantifying Impact and Likelihood

Quantifying impact and likelihood is essential for creating a robust risk assessment. Impact refers to the potential negative consequences of a risk event, while likelihood quantifies the probability of that event occurring.

- Impact can be assessed qualitatively (e.g., low, medium, high) or quantitatively (e.g., estimated financial loss, production downtime). Qualitative assessments are useful for initial screening, while quantitative assessments provide more precise insights. Examples of qualitative impact include disruptions in product delivery (low, medium, high), damage to company reputation (low, medium, high), and supply chain disruptions (low, medium, high).

Quantitative examples might involve financial losses (e.g., $10,000, $100,000, $1,000,000) or estimated downtime (e.g., 1 day, 1 week, 1 month).

- Likelihood is the probability of a risk event occurring. Qualitative assessments often use categories such as rare, unlikely, possible, likely, almost certain. Quantitative methods might employ historical data or expert judgment to assign numerical probabilities (e.g., 10%, 50%, 90%). Examples of likelihood assessments might involve the probability of a natural disaster (rare, unlikely, possible, likely, almost certain) or the chance of a supplier experiencing a production issue (rare, unlikely, possible, likely, almost certain).

Risk Matrix Table

A risk matrix provides a visual representation of the combined impact and likelihood of risks. This table helps in prioritizing risks for mitigation.

Supply chain risk assessment is crucial for any business, big or small. Think about how a disruption in the production of in-game items for a popular game like League of Legends, particularly through the league of legends indie spinoffs riot forge program, could impact its player base and financial success. Ultimately, understanding these potential vulnerabilities is key to maintaining a robust and resilient supply chain.

| Risk Event | Impact | Likelihood | Risk Score |

|---|---|---|---|

| Supplier Factory Closure | High (major financial loss) | Medium (possible within next 6 months) | High |

| Shipping Delays | Medium (moderate financial loss) | High (likely due to port congestion) | High |

| Raw Material Shortage | High (major production disruption) | Low (unlikely but could happen) | Medium |

| Cyberattack | High (massive data breach) | Medium (possible within the next year) | High |

Qualitative and Quantitative Risk Assessment Methods

Qualitative methods use descriptive terms (e.g., low, medium, high) to assess impact and likelihood. Quantitative methods employ numerical values to represent these factors. Examples of qualitative methods include SWOT analysis, expert panels, and checklists. Examples of quantitative methods include simulations, statistical analysis, and financial modeling.

Risk Register

A risk register is a document used to track and manage identified risks. It serves as a central repository for information about each risk, including its description, impact, likelihood, assigned owner, mitigation strategies, and status.

Prioritizing Risks

Prioritizing risks based on their potential impact and likelihood allows for focused mitigation efforts. Risks with high scores (high impact and high likelihood) should be addressed immediately. Risks with low scores (low impact and low likelihood) can be monitored. The risk matrix is critical for this process, enabling companies to prioritize their mitigation efforts.

Developing Mitigation Strategies

Successfully navigating supply chain risks hinges on proactive mitigation strategies. These strategies are not simply reactive measures, but rather integral components of a robust supply chain management system. They require a deep understanding of potential vulnerabilities, careful assessment of risk impact and likelihood, and the development of concrete plans for response. A well-defined mitigation plan can transform a potential crisis into a manageable challenge.

Key Principles of Effective Mitigation Strategies

Effective mitigation strategies are built upon several key principles. They must be tailored to the specific risks identified, encompassing both the likelihood and the potential impact of those risks. Proactive strategies are crucial, as they anticipate potential issues and establish preventative measures rather than simply responding to problems after they arise. Flexibility and adaptability are also vital, as supply chain environments are dynamic and unpredictable.

Strategies must be capable of adapting to evolving conditions and new challenges. Finally, communication and collaboration across all stakeholders are essential for successful implementation.

Different Mitigation Strategies for Various Risks

Mitigation strategies need to be diverse and adaptable to the type of risk. For supplier-related risks, such as political instability or natural disasters in a supplier’s region, diversification of suppliers is a common strategy. This involves establishing relationships with multiple suppliers in different locations, reducing reliance on a single source. For disruptions in transportation, strategies might include establishing alternative transportation routes, or using robust contingency plans.

For example, in the case of a port closure, companies could utilize rail or trucking options. When faced with security risks, companies can invest in security measures and implement robust internal controls.

Importance of Proactive Risk Management

Proactive risk management is crucial in minimizing the impact of potential disruptions. By anticipating potential risks and implementing preventative measures, companies can avoid costly delays and disruptions. Proactive strategies allow companies to stay ahead of the curve, ensuring business continuity. This approach shifts the focus from crisis management to continuous improvement. Companies are able to respond to potential challenges with well-defined, pre-emptive plans, rather than scrambling to react once a crisis hits.

Mitigation Strategy Table

| Risk | Mitigation Strategy | Implementation Plan | Expected Outcomes |

|---|---|---|---|

| Supplier Dependence | Diversification of Suppliers | Identify and vet multiple suppliers in different regions. Establish contracts with backup suppliers. | Reduced reliance on a single supplier. Increased resilience to disruptions in a single region. |

| Transportation Disruptions | Alternative Transportation Routes | Identify alternate transportation modes (trucking, rail, air). Develop contingency plans for specific disruptions. | Reduced vulnerability to disruptions in primary transportation routes. Increased flexibility in response to unexpected events. |

| Natural Disasters | Geographic Diversification of Operations | Establish operations in multiple locations to minimize the impact of regional disasters. | Reduced impact of localized disruptions. Maintained operational continuity during major natural events. |

| Cybersecurity Breaches | Robust Cybersecurity Measures | Implement strong firewalls, intrusion detection systems, and employee training programs. | Reduced risk of data breaches and system disruptions. Increased protection against cyberattacks. |

Potential Challenges in Implementing Mitigation Strategies

Implementing mitigation strategies can be challenging. Cost is often a significant hurdle, as diversification of suppliers or investing in security measures can be expensive. Coordination across different departments and stakeholders is another challenge. Ensuring all parties are on board and understand their roles can be complex. Resistance to change from employees accustomed to existing processes can also pose a problem.

Supply chain risk assessment is crucial, especially for massive operations like the world’s biggest phone factory, Samsung India. Understanding potential disruptions, from material shortages to geopolitical instability, is paramount. A robust risk assessment for a company like Samsung India needs to consider every possible snag in their complex global supply chain. This careful evaluation is essential to ensure smooth production and maintain a competitive edge.

Finally, accurately predicting and preparing for every possible risk is nearly impossible.

Supply chain risk assessment is crucial for any business, especially when considering the potential for disruptions. A recent purchase I made, a DJI Osmo Pocket microphone mic adapter, dji osmo pocket microphone mic adapter price features , highlighted how easily supply chains can be impacted. Understanding the potential for delays or price fluctuations is vital to proactively mitigate risk and ensure business continuity.

Examples of Successful Mitigation Strategies

A successful example of mitigation strategy involves a company that identified a potential disruption in its supply chain due to political instability in a key supplier’s region. The company proactively diversified its supplier base, establishing relationships with suppliers in more stable regions. This strategy allowed them to maintain operations without significant disruption when the predicted political instability occurred.

Another example involves a company that experienced a major transportation disruption due to a natural disaster. The company’s well-defined alternative transportation plan allowed them to reroute their shipments, ensuring continued delivery of critical goods.

Implementing and Monitoring the Assessment

Successfully implementing a supply chain risk assessment program requires a structured approach that integrates the identified risks into daily operations. This proactive strategy minimizes potential disruptions and enhances resilience. The process necessitates a commitment from all stakeholders, fostering a culture of vigilance and preparedness.Implementing a comprehensive supply chain risk assessment program necessitates a multi-step process. This involves the establishment of clear roles and responsibilities, ensuring that everyone understands their part in the assessment process.

The program should be tailored to the specific needs and characteristics of the supply chain, taking into account factors such as the industry, geographical location, and types of suppliers.

Establishing a Risk Assessment Program

Implementing a robust supply chain risk assessment program demands a structured and ongoing process. This involves creating a dedicated team with clearly defined roles and responsibilities. Documentation is key, including policies, procedures, and guidelines, providing a consistent framework for risk assessment.

Continuous Monitoring and Review

Continuous monitoring and review are critical components of a successful supply chain risk assessment program. Supply chains are dynamic environments; risks evolve, and new vulnerabilities emerge. Regular reviews allow for adjustments to mitigation strategies and proactive responses to changing circumstances.

Integrating Risk Assessment into Existing Processes

Integrating risk assessment into existing supply chain processes is crucial for seamless implementation. This integration should encompass all stages of the supply chain, from procurement and manufacturing to distribution and delivery. A key aspect of this integration is the development of specific procedures and protocols for identifying, evaluating, and mitigating risks at each stage.

Using Key Performance Indicators (KPIs)

Key performance indicators (KPIs) are essential tools for monitoring the effectiveness of mitigation strategies. Examples include supplier performance metrics, delivery timeliness, and inventory turnover rates. By tracking these KPIs, organizations can identify trends and patterns that may indicate emerging risks or the effectiveness of implemented mitigation strategies. A dashboard showcasing these KPIs provides a clear visual representation of the overall health and resilience of the supply chain.

Best Practices for Reporting

Effective reporting on supply chain risk assessments is crucial for transparency and accountability. Reports should be clear, concise, and readily understandable, providing a summary of key findings, risk ratings, and proposed mitigation strategies. Regular reporting to stakeholders ensures transparency and fosters trust.

Communicating Risk Assessment Findings

Communicating risk assessment findings to stakeholders is vital for effective risk management. Clear communication ensures that all relevant parties understand the risks, their potential impact, and the proposed mitigation strategies. Different stakeholders may require different levels of detail; therefore, tailored communication strategies are essential. This includes not only top management but also employees involved in the daily operations of the supply chain.

Risk Assessment Tools and Technologies

Numerous risk assessment tools and technologies can aid in the process. Software applications, including risk management platforms, provide structured frameworks for identifying, analyzing, and mitigating risks. These tools can automate tasks, track key performance indicators (KPIs), and enhance the overall efficiency of the risk assessment process. Examples include advanced analytics tools and machine learning algorithms that can predict potential disruptions and optimize supply chain operations.

Case Studies of Supply Chain Risk Assessment

Understanding supply chain risks isn’t just theoretical; it’s about learning from real-world experiences. Successful risk assessments are crucial for building resilience and avoiding costly disruptions. Conversely, inadequate assessments can lead to significant consequences, as we’ll see in the case studies below.

Successful Supply Chain Risk Assessment: The Case of Foxconn

Foxconn, a major electronics manufacturer, faced a significant risk related to its reliance on a single supplier for a critical component. A comprehensive supply chain risk assessment identified the vulnerability and highlighted the potential for disruption. Foxconn then implemented a diversification strategy, sourcing the component from multiple suppliers. This diversification mitigated the risk of a single point of failure.

The assessment process allowed Foxconn to proactively address the potential issue and avoid potential production bottlenecks or delays. This resulted in a more resilient supply chain, able to withstand unforeseen circumstances.

Inadequate Supply Chain Risk Assessment: The Case of the 2011 Japanese Earthquake

The 2011 Tōhoku earthquake and tsunami severely impacted global supply chains, particularly those reliant on Japanese manufacturing. Many companies had not adequately assessed the risks associated with geographically concentrated suppliers or critical infrastructure in Japan. The lack of preparedness led to significant disruptions in production, shortages of critical components, and substantial financial losses for businesses that hadn’t planned for such a catastrophic event.

The failure to foresee and account for the impact of such a significant event resulted in a loss of resilience in the global supply chain. This case emphasizes the importance of considering geopolitical instability and natural disasters as potential supply chain disruptions.

Comparison of Case Studies

| Case Study | Risk | Mitigation Strategy | Outcome |

|---|---|---|---|

| Foxconn | Single-supplier dependency for a critical component | Diversification of component sourcing | Increased supply chain resilience, avoided production bottlenecks, and maintained operational continuity. |

| 2011 Japanese Earthquake | Geopolitical instability and natural disaster risk (earthquake and tsunami), geographic concentration of suppliers, and critical infrastructure vulnerability | Lack of adequate assessment and proactive mitigation strategies. | Significant supply chain disruptions, production halts, component shortages, and substantial financial losses. |

Closing Summary: Supply Chain Risk Assessment

In conclusion, a thorough supply chain risk assessment isn’t a one-time exercise; it’s an ongoing process that requires vigilance and adaptability. By consistently evaluating risks, developing mitigation strategies, and monitoring their effectiveness, businesses can significantly reduce vulnerabilities and build a more resilient and sustainable supply chain.

This guide has provided a framework for understanding the complexities involved, offering practical steps for implementing a robust assessment process. From identifying vulnerabilities to developing mitigation strategies, each step is vital in fortifying your supply chain against future disruptions.