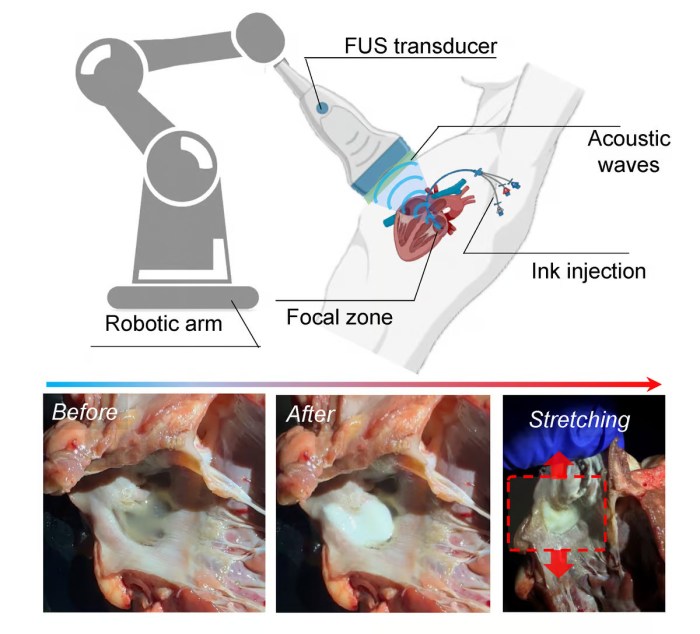

Sound waves could 3D print implants inside your body, opening a fascinating new frontier in medical technology. Imagine precisely crafted, customized implants, tailored to your unique needs, built using sound waves. This innovative approach uses sound waves to manipulate materials, creating intricate structures within the body. From the fundamental principles behind this technology to the potential applications and challenges, this exploration delves into the exciting possibilities of this emerging field.

This innovative method promises to revolutionize implant creation, offering a pathway to personalized medicine and potentially enhancing patient outcomes. The detailed exploration of the technology’s mechanics, materials, and potential safety concerns will provide valuable insights for those interested in the future of medical advancements.

Introduction to Sound Wave Implants

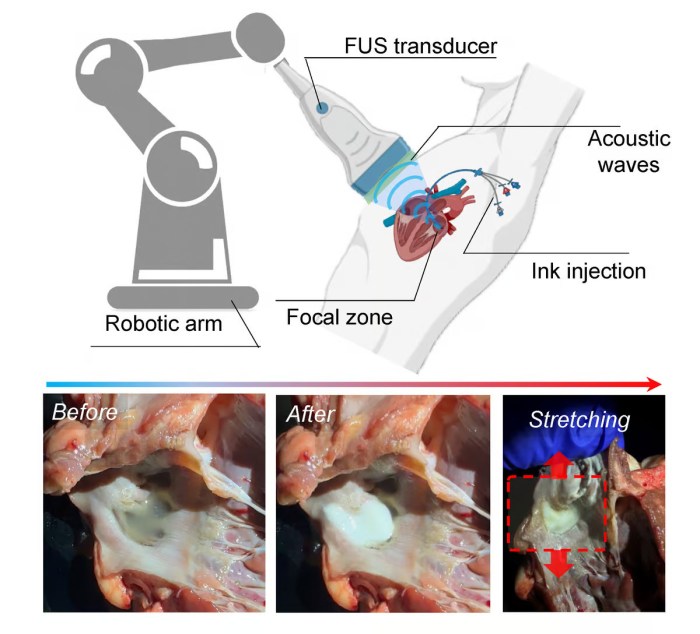

Sound waves, often associated with music and communication, possess a hidden potential for intricate material manipulation. This transformative ability opens up exciting possibilities for creating customized implants within the human body. Imagine precisely shaping and positioning biocompatible materials, eliminating the need for invasive surgical techniques and fostering faster healing times. This revolutionary approach relies on the meticulous control of sound waves to orchestrate the precise placement of materials, paving the way for personalized healthcare solutions.The fundamental principle behind using sound waves for 3D printing implants is based on their ability to generate localized pressure and energy.

This controlled energy deposition enables the precise arrangement of biocompatible materials, creating complex structures. Specific frequencies of sound waves interact with the material in a way that enables controlled melting, solidification, and alignment. The result is a precise 3D printing process, unlike any conventional technique.

Types of Sound Waves Employed

Various types of sound waves can be utilized for this innovative process. Ultrasound, with its high frequency, offers exceptional precision for manipulating materials. The specific frequencies are meticulously chosen to match the desired response of the material. Other sound waves, such as infrasound, can also be employed. The selection depends on the specific material and desired implant shape.

These waves can be generated by piezoelectric devices or specialized transducers.

Potential Benefits of Sound Wave Implant Creation

The use of sound waves in 3D printing implants promises several advantages. Firstly, the non-invasive nature of the process minimizes the need for significant incisions, reducing patient discomfort and recovery time. Secondly, the precision of sound-wave manipulation allows for the creation of highly customized implants tailored to individual patient needs. This personalization enhances the efficacy and safety of the implant, leading to superior patient outcomes.

Furthermore, the 3D printing technique potentially lowers costs associated with traditional manufacturing processes, making advanced healthcare more accessible.

Challenges Associated with Sound Wave Implant Creation

Despite the numerous advantages, challenges remain in the practical implementation of sound wave-based implant creation. One significant hurdle is the precise control of energy deposition at the nanoscale. Precisely controlling the interaction of sound waves with different materials and their behavior under specific conditions remains a complex scientific problem. Another challenge lies in the development of robust and biocompatible materials that can withstand the effects of sound waves without degradation.

Imagine sound waves precisely shaping implants inside your body – a truly fascinating prospect. But while that’s groundbreaking, let’s not forget the other significant costs involved in major life changes, like buying a home. For example, mortgage payments are just the start; here’s what homeownership really costs – it’s more than just the monthly payment.

This complex reality reminds us that even seemingly futuristic advancements like 3D-printed implants within the human body have their practical, real-world implications.

Material Manipulation by Sound Waves

| Material | Frequency (Hz) | Method | Result |

|---|---|---|---|

| Calcium Phosphate | 20-100 kHz | Ultrasound-assisted deposition | Formation of porous structures |

| Titanium Alloy | 100-500 kHz | Focused ultrasound | Precise shaping and structuring |

| Polyurethane | 500 kHz – 1 MHz | Low-intensity ultrasound | Controlled solidification |

| Collagen | 50-100 kHz | Acoustic cavitation | Improved biocompatibility |

The table above illustrates the potential of sound waves to manipulate different biocompatible materials, showcasing the versatility of this approach. Each material responds uniquely to different frequencies and methods, allowing for targeted material manipulation.

3D Printing Methods and Procedures

The realm of 3D printing is rapidly evolving, offering innovative possibilities for creating intricate structures, including medical implants. This exploration delves into the specific application of 3D printing methods, focusing on their utility in crafting sound wave-based implants. The precision and material selection are paramount to ensure the implants effectively interact with the body’s auditory system and promote healing.The application of sound waves for 3D printing presents unique advantages, especially in creating complex geometries that are difficult to achieve with traditional methods.

Imagine sound waves 3D printing implants directly inside your body – pretty cool, right? While that’s a fascinating medical advancement, have you considered how to streamline your meal prep? Perhaps exploring a service like tovala smart oven recipe meal service buy could free up your time to focus on other exciting health innovations. The precision of these sound-wave implant procedures is quite remarkable, isn’t it?

Precise control over material deposition is crucial, allowing for intricate patterns and structures within the implant. This technology could revolutionize the field of implantology by allowing for personalized implants tailored to each patient’s specific needs.

Different 3D Printing Methods

Various 3D printing techniques offer distinct advantages and disadvantages for crafting sound wave-based implants. Understanding these differences is crucial for selecting the optimal method.

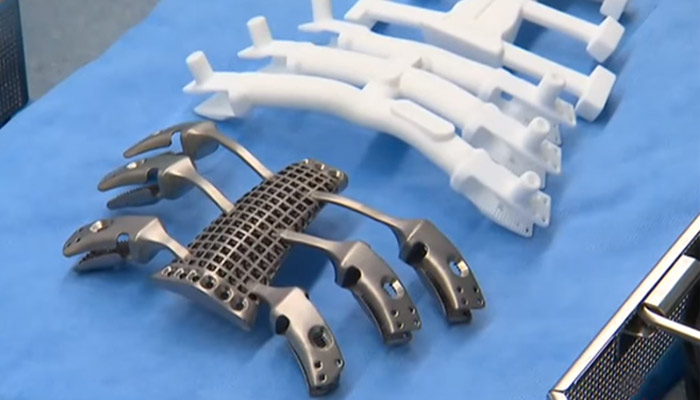

- Stereolithography (SLA): This method uses a laser to cure liquid resin, layer by layer, to build up the desired shape. It provides high precision and fine detail, but the process can be relatively slow and the material choice is limited to photopolymers. The precision attainable is valuable for intricate implant designs. However, the use of photopolymers might present compatibility issues with the body.

- Selective Laser Sintering (SLS): This technique employs a laser to selectively melt and fuse powdered materials, creating the object layer by layer. SLS is suitable for a wider range of materials, including metals and polymers, offering more mechanical strength. However, the process may not yield the same level of fine detail as SLA, and there are concerns about the potential for material porosity.

- Material Jetting: This method uses a print head to jet droplets of material onto a substrate. Material jetting offers good flexibility in material choice and allows for high-speed printing, making it suitable for creating large-scale implants. However, the accuracy of the process may not be as high as that of SLA or SLS. This method is particularly promising for large-scale implant production.

- Direct Energy Deposition (DED): This technique uses a high-powered laser or electron beam to melt and deposit material in a controlled manner. DED is well-suited for building complex structures and intricate designs, particularly with metallic materials. However, the process can be energy-intensive and may require specialized equipment.

Sound Wave-Based Deposition Procedures

The procedures for depositing and shaping materials using sound waves are fundamentally different from conventional 3D printing techniques. Acoustic fields, specifically tailored frequencies and intensities, are employed to guide and manipulate the deposition of biocompatible materials.

- Material Selection: The choice of biocompatible materials is critical for the success of sound wave-based implants. Biocompatibility, mechanical properties, and biodegradability need to be considered to ensure long-term functionality and safety.

- Acoustic Field Engineering: Designing the appropriate acoustic field is essential for precise material deposition. This includes defining the frequency, intensity, and spatial distribution of the sound waves. The precise control of the sound wave pattern is vital to deposit materials precisely.

- Instrumentation: Specialized acoustic equipment, including transducers, amplifiers, and sensors, are necessary for generating and controlling the sound waves. The instrumentation for generating the specific sound waves is complex and requires advanced control systems.

Comparison of 3D Printing Methods, Sound waves could 3d print implants inside your body

| Method | Material Properties | Advantages/Disadvantages |

|---|---|---|

| Stereolithography (SLA) | Photopolymers | High precision, fine detail, but slow, limited material choices. |

| Selective Laser Sintering (SLS) | Metals, polymers | Wider material range, but lower precision, potential for porosity. |

| Material Jetting | Various | High speed, flexible material choice, but lower accuracy. |

| Direct Energy Deposition (DED) | Metals | Complex structures, intricate designs, but energy-intensive. |

Factors Influencing Precision and Accuracy

Several factors influence the precision and accuracy of the sound wave-based printing process. These include the control over the acoustic field, the characteristics of the materials being used, and the complexity of the desired implant geometry.

- Acoustic Field Control: The ability to precisely control the sound wave field is critical to the accuracy of the printing process. Variations in intensity and frequency can lead to inaccuracies in material placement.

- Material Properties: The viscosity, density, and adhesion properties of the material being deposited play a significant role in the quality of the final print. Uniformity in material properties is essential for precision.

- Geometry Complexity: The complexity of the desired implant geometry directly impacts the difficulty of the printing process. Complex shapes may require multiple stages or specialized acoustic fields for accurate construction.

Creating Complex Implant Geometries

Creating complex implant geometries with sound waves requires sophisticated approaches to manipulate the material deposition process. These approaches may include combining different acoustic fields or using adaptive control systems.

- Multi-frequency Acoustic Fields: Employing different frequencies of sound waves to manipulate the deposition process can create complex structures with specific material distributions. Using multiple frequencies to achieve specific geometric shapes is promising.

- Adaptive Control Systems: Implementing adaptive control systems that adjust the acoustic field parameters in real-time can further enhance the precision and accuracy of complex geometry creation. Adapting to the material’s behavior in real-time is key for complex shapes.

Material Compatibility and Biocompatibility

The success of sound wave-based 3D printing of implants hinges critically on the careful selection of biocompatible materials. Choosing materials that not only integrate seamlessly with the body’s tissues but also withstand the long-term mechanical and biological stresses is paramount. The interaction between the chosen material and the body’s environment must be thoroughly understood to ensure the implant’s longevity and effectiveness.

Understanding the potential risks and limitations associated with each material is vital for developing safe and reliable implants.Selecting materials that are not only compatible with the body but also respond favorably to the energy transfer from sound waves is a key consideration. The body’s response to foreign materials can vary significantly, depending on the material’s chemical composition and its structure.

The long-term effects of the implant must be thoroughly investigated to ensure it does not trigger an adverse reaction in the recipient’s body.

Suitable Materials for Sound Wave-Based Implant Printing

A wide range of biocompatible materials can be considered for 3D printing implants using sound waves. Polymers, ceramics, and metals each present unique advantages and disadvantages in terms of biocompatibility and interaction with sound waves. The ideal material will depend on the specific application and the desired properties of the implant.

Biocompatibility of Different Materials

Biocompatibility refers to the ability of a material to interact safely and favorably with living tissues. Factors influencing biocompatibility include the material’s chemical composition, surface characteristics, and mechanical properties. Different materials exhibit varying degrees of biocompatibility, some integrating seamlessly with the body’s tissues while others trigger adverse reactions.

Long-Term Effects of Sound Wave Implants

The long-term effects of implants on the human body are complex and multifaceted. Potential issues include immune responses, tissue rejection, and mechanical wear. The selection of materials with low immunogenicity and resistance to degradation is crucial for minimizing long-term complications. The interaction of the material with the sound waves must be considered over extended periods.

Material Selection for Implant Longevity and Function

Material selection is crucial for ensuring the longevity and function of the implant. Materials with high mechanical strength, good elasticity, and resistance to degradation are preferable. The material’s ability to withstand the stresses imposed by the body and the forces associated with sound wave treatment is essential. Materials with a high degree of stability and resistance to corrosion are favored.

Material Compatibility Testing Procedures

Rigorous testing procedures are essential to evaluate the compatibility of materials with biological environments. In vitro tests, such as cell culture studies and tissue compatibility assays, can assess the material’s potential to induce inflammation or cytotoxicity. In vivo studies in animal models are necessary to evaluate the material’s long-term effects and to identify any potential adverse reactions. The testing process should consider the potential for sound wave interactions and their influence on the materials.

Material Compatibility Table

| Material | Biocompatibility | Sound Wave Interaction | Potential Issues |

|---|---|---|---|

| Titanium Alloy | Generally good, bio-inert | Good, minimal interaction | Potential for allergic reactions in some individuals, corrosion |

| Poly-L-lactic acid (PLLA) | Biodegradable, good initial biocompatibility | May require modification for optimal sound wave interaction | Potential for degradation over time, mechanical strength limitations |

| Hydroxyapatite | Good bone bonding, biocompatible | Potential for improved bone growth due to sound wave stimulation | Potential for poor mechanical strength, may require reinforcement |

| Polyetheretherketone (PEEK) | Excellent biocompatibility, high strength | Good, high stiffness and modulus, potential for improved implant stability | Potential for high cost, limited biodegradability |

Safety and Efficacy

Sound wave-based 3D printing of implants presents exciting possibilities, but also necessitates meticulous attention to safety and efficacy. Ensuring the procedure is both safe and effective is paramount, requiring a multifaceted approach encompassing rigorous testing, careful material selection, and precise monitoring of implant performance. This section explores the critical safety considerations and efficacy measures associated with this emerging technology.

Potential Safety Concerns

The use of sound waves to manipulate biomaterials within the body introduces potential safety concerns. These concerns stem from the localized heating effects of the sound waves, the possibility of unintended material degradation, and the need for precise control of the printing process to avoid damage to surrounding tissues. The intensity and duration of the sound waves must be carefully regulated to prevent thermal damage to sensitive biological structures.

Furthermore, the materials used in the printing process must be thoroughly evaluated for their biocompatibility and long-term effects on the body.

Necessary Precautions and Safety Measures

Implementing robust safety protocols is crucial to mitigate potential risks. These precautions include employing advanced imaging techniques to monitor the printing process in real-time, and employing temperature sensors to precisely measure and regulate the localized temperature during printing. The use of non-toxic, biocompatible materials is essential, along with rigorous testing protocols to evaluate the material’s long-term effects on the body.

Imagine sound waves precisely 3D printing implants inside your body – a fascinating prospect! To manage the complex data streams and security protocols needed for such a technology, a robust enterprise browser like what is an enterprise browser would be crucial. This advanced software is vital for controlling the intricate processes involved in these revolutionary implant procedures, ensuring seamless integration and maximum safety.

Furthermore, establishing clear safety guidelines for operators and patients is critical.

Monitoring Implant Efficacy

Post-implantation monitoring is essential to assess the implant’s efficacy and longevity. This involves a combination of non-invasive imaging techniques, such as X-rays and CT scans, to track the implant’s integration with surrounding tissues. Regular blood tests and physical examinations can help detect any adverse reactions or complications. Furthermore, tracking the implant’s functionality over time can provide valuable insights into its performance and potential long-term effects.

Careful record-keeping of patient data is also crucial for analyzing trends and refining future procedures.

Potential Side Effects or Complications

Potential side effects may include localized inflammation, tissue damage, and allergic reactions to the materials used in the implant. The severity of these side effects depends on various factors, including the intensity of the sound waves, the characteristics of the materials used, and the patient’s individual response. Thorough pre-clinical testing on animal models can help to predict and mitigate potential risks before human trials.

Furthermore, careful patient selection and comprehensive pre-operative assessments are crucial for minimizing complications.

Importance of Rigorous Testing and Validation

Rigorous testing and validation are paramount to ensure the safety and efficacy of sound wave-based implant technology. This involves in-vitro studies using cell cultures to evaluate material biocompatibility and in-vivo studies on animal models to assess the implant’s performance and potential complications. These studies must adhere to strict ethical guidelines and protocols to ensure the safety and well-being of the subjects.

Furthermore, these rigorous tests are crucial for establishing a safety profile for the implants and ensuring their suitability for human use.

Safety Protocols and Procedures

| Safety Protocol | Procedure Description |

|---|---|

| Pre-implantation Testing | Thorough evaluation of materials for biocompatibility and toxicity. |

| Real-time Monitoring | Employing advanced imaging techniques to monitor the printing process and adjust parameters as needed. |

| Post-implantation Monitoring | Regular follow-up appointments to assess implant integration and detect any complications. |

| Material Selection | Prioritizing non-toxic and biocompatible materials. |

| Safety Guidelines | Establishing clear safety protocols for medical personnel. |

Applications and Future Directions

Sound wave-based 3D printing of implants opens a Pandora’s box of possibilities in medicine. Imagine intricate, personalized bone grafts, precisely tailored to a patient’s unique anatomical needs, or vascular scaffolds meticulously designed to restore blood flow. This technology, still in its nascent stages, promises to revolutionize surgical procedures and patient outcomes. The potential for customized, highly effective treatments is vast, demanding a careful consideration of both the practical applications and the ethical implications.The future of medicine hinges on our ability to adapt and improve existing technologies.

Sound wave 3D printing is poised to become a transformative tool, allowing for the creation of complex structures with unparalleled precision. The process of creating these structures inside the body could lead to significantly enhanced surgical precision, minimized invasiveness, and accelerated healing times.

Potential Applications

Sound waves, with their ability to deposit biocompatible materials with precision, offer several exciting avenues for medical advancement. These applications range from tissue regeneration to personalized drug delivery systems. One example is the development of intricate bone scaffolds for fracture repair, where the shape and porosity can be meticulously designed to stimulate natural bone growth. Another is creating specialized implants that precisely target diseased tissues, enabling targeted drug delivery or minimizing damage to healthy surrounding tissues.

Hypothetical Medical Application Scenario

A patient suffering from a severe spinal cord injury is experiencing debilitating paralysis. Traditional treatments may not be effective. Using sound wave-based 3D printing, a customized spinal cord scaffold could be created and implanted precisely along the damaged area. The scaffold would be designed to guide the regeneration of nerve cells, promoting neural connections and potentially restoring motor function.

The scaffold material would be biocompatible and biodegradable, allowing for the body to gradually absorb the scaffold while the new tissue grows. This process could potentially restore lost function and significantly improve the patient’s quality of life.

Steps to Clinical Translation

Several critical steps are necessary to translate research into clinical practice. Rigorous animal studies are crucial to assess safety and efficacy in a controlled environment. Detailed simulations and computational models must accurately predict the implant’s performance in the body. Furthermore, the development of a standardized manufacturing process and quality control measures is paramount to ensure consistency and reliability.

Finally, the ethical implications of using this technology must be thoroughly examined and addressed.

Future Directions and Advancements

Advancements in this field will likely focus on improving material selection, enhancing the resolution of the printing process, and exploring new applications. For instance, incorporating advanced biomaterials that mimic the body’s natural tissues will lead to more effective and durable implants. Simultaneously, refining the printing process will enable more complex and intricate designs, opening up possibilities for more complex anatomical repairs.

Integration with existing medical imaging techniques will facilitate precise implant placement.

Table of Applications and Benefits

| Application | Benefits |

|---|---|

| Bone fracture repair | Personalized bone scaffolds promoting faster healing and reduced recovery time. |

| Vascular repair | Creation of personalized vascular grafts with enhanced biocompatibility and improved blood flow. |

| Cartilage regeneration | Customized cartilage replacements promoting smoother joint movement and reducing pain. |

| Drug delivery | Targeted drug delivery to specific tissues, reducing side effects and enhancing treatment efficacy. |

Epilogue: Sound Waves Could 3d Print Implants Inside Your Body

In conclusion, the prospect of using sound waves to 3D print implants is truly remarkable. While challenges remain, the potential benefits are substantial, from personalized treatment to improved patient outcomes. Further research and development are crucial to overcome these obstacles and pave the way for this transformative technology to enter clinical practice. The future of implantology could well depend on these advances.