Samsung 4TB SSD QLC storage mass production is poised to revolutionize consumer electronics. This massive undertaking promises a significant increase in storage capacity at a potentially lower cost, thanks to the QLC NAND technology. Expect to see this innovative technology trickle down to laptops, desktops, and even gaming consoles, making high-capacity storage more accessible than ever. But what are the specific challenges and benefits of mass producing these powerful drives?

Let’s dive into the details.

The manufacturing process itself is a complex dance of intricate steps, from chip fabrication to final assembly. Quality control is paramount, ensuring the reliability and durability of these 4TB drives. We’ll explore the potential environmental impact, cost analysis, and the competitive landscape Samsung faces. It’s a fascinating look at how advancements in storage technology are impacting the tech world.

Introduction to Samsung 4TB QLC SSD Mass Production

Samsung’s commitment to expanding storage capacity continues with the announcement of mass production for its 4TB QLC (Quad-Level Cell) SSDs. This represents a significant milestone in the evolution of solid-state storage, offering increased storage density at a potentially competitive price point. This development promises to reshape the consumer electronics landscape, impacting everything from personal computers to data centers.This technology leverages advanced QLC NAND flash memory, a cost-effective alternative to TLC (Triple-Level Cell) and even more advanced technologies.

Mass production allows for economies of scale, potentially lowering the cost per gigabyte for consumers and opening new possibilities for large-scale storage solutions.

Overview of Samsung 4TB QLC SSD Technology

Samsung’s 4TB QLC SSD technology utilizes Quad-Level Cell NAND flash memory, which encodes four bits of data per cell. This allows for greater storage density compared to previous generations of SSDs, like TLC, and offers a compelling balance between capacity and cost. This advancement in density is crucial for applications demanding large storage capacities, like high-resolution video editing, extensive data backup, and advanced gaming.

Key Features and Benefits

The key features of Samsung’s 4TB QLC SSD include its significant capacity, improved performance relative to previous QLC implementations, and a focus on endurance and reliability. This translates to substantial benefits for consumers and businesses, enabling larger data storage for personal use or professional applications, such as backing up large amounts of digital content, storing high-definition video, or running intensive software and gaming applications.

Significance of Mass Production

Mass production of the 4TB QLC SSD is crucial for making this technology accessible and cost-effective. The high volume production allows Samsung to leverage economies of scale, leading to lower per-gigabyte costs, and making this high-capacity storage more affordable for a wider range of consumers. This also increases the availability and potential for greater adoption of this storage technology across various applications, from personal use to professional data centers.

Potential Impact on the Consumer Electronics Market

The availability of this high-capacity QLC SSD will undoubtedly impact the consumer electronics market. For example, PCs and laptops will benefit from increased storage capacity, without sacrificing performance or having to resort to multiple drives. This expansion in storage will also fuel the growth of cloud storage and other data-intensive applications, like video streaming and cloud gaming. It’s anticipated that the cost reduction, brought about by mass production, will also attract new users, especially in the PC market.

Possible Use Cases

The 4TB QLC SSD has a wide range of potential applications:

- Personal Computers and Laptops: Users can store massive libraries of high-resolution photos, videos, and large programs, eliminating the need for frequent data transfers and backups. This significantly increases the user experience by allowing for fast boot times, faster loading times for applications, and a streamlined user interface.

- Data Centers: The high capacity enables data centers to store enormous amounts of data, supporting various applications, such as big data analytics, AI training, and high-performance computing. This is especially relevant in an increasingly data-driven world, where the need for reliable and cost-effective storage is paramount.

- Cloud Storage: The increased storage capacity will allow for more data to be stored and accessed via cloud platforms, improving accessibility and usability. This will be particularly beneficial for users who require high storage capacity for their digital files.

- Gaming Consoles and VR/AR Devices: Gaming and immersive technologies require massive amounts of data to operate smoothly. This storage solution can accommodate the massive data demands of these technologies, potentially reducing load times and increasing overall performance.

Manufacturing Process and Technology

The mass production of Samsung’s 4TB QLC SSDs marks a significant advancement in storage technology. This involves a complex interplay of sophisticated manufacturing processes, meticulously refined materials, and advanced control systems to ensure reliability and performance at scale. The intricate nature of these processes demands rigorous quality control and optimization to meet the demands of a rapidly evolving technological landscape.The journey from raw materials to a fully functional 4TB QLC SSD is a multifaceted process.

It encompasses numerous stages, each crucial to the overall quality and performance of the final product. Understanding these stages provides insight into the engineering prowess required to bring such a high-capacity storage solution to market.

Stages in Mass Production

The manufacturing process of a 4TB QLC SSD involves numerous tightly integrated steps. These stages, from material acquisition to final testing, demand meticulous attention to detail. Maintaining consistent quality across such a vast production run is a significant challenge.

- Material Procurement and Characterization: High-purity materials, including silicon wafers for the controller chips and specialized memory cells for QLC storage, are carefully sourced and characterized. Rigorous testing ensures these materials meet stringent specifications to guarantee optimal performance and reliability.

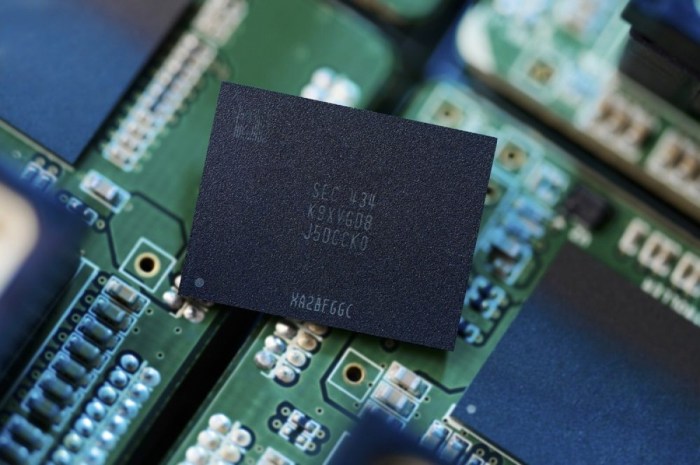

- Chip Fabrication: The creation of the NAND flash memory chips, the heart of the QLC SSD, is a complex semiconductor process. Advanced lithography techniques are used to etch intricate patterns onto silicon wafers. These processes must be highly controlled to ensure the uniformity of the memory cells.

- Memory Cell Programming and Testing: Once the NAND flash memory chips are fabricated, they undergo extensive programming and testing to ensure proper QLC data storage and retrieval. This process is crucial for validating the ability of the memory cells to retain and accurately access the data.

- Controller Integration: The controller chip, responsible for managing data transfer and storage operations, is integrated with the NAND flash memory. This precise integration is critical for efficient data management and overall performance.

- Module Assembly and Testing: Individual components are assembled into complete SSD modules. This process involves precise alignment and soldering, ensuring optimal electrical connections and signal integrity. Comprehensive testing procedures validate the functional integrity of each module.

- Quality Assurance and Packaging: Rigorous quality assurance checks are performed at each stage of the manufacturing process. This includes verifying data integrity, performance metrics, and reliability characteristics. Finally, the SSDs are packaged for shipping and distribution, ensuring product protection throughout the supply chain.

Crucial Technologies

Advanced technologies are indispensable in the mass production of high-capacity QLC SSDs. These innovations drive the efficiency, cost-effectiveness, and quality of the manufacturing process.

- Advanced Lithography: The ability to create intricate patterns on silicon wafers at extremely small scales is crucial for packing more memory cells onto a single chip. This process allows for higher storage densities. Improvements in lithography directly translate to improved storage capacity in devices.

- QLC NAND Technology: The QLC (Quad-Level Cell) technology used in these SSDs allows for higher storage density by encoding multiple bits of data into a single cell. This is achieved through sophisticated encoding and decoding algorithms.

- Controller Optimization: The controller’s role in managing data transfer, error correction, and performance is crucial. Sophisticated algorithms and advanced control mechanisms ensure efficient data management and optimize performance.

- Automated Testing and Inspection: Automated systems for testing and inspecting each component and the final SSDs are critical for maintaining consistent quality and detecting defects at various stages. These systems improve efficiency and minimize errors.

Challenges and Limitations

Mass production of 4TB QLC SSDs presents unique challenges.

- Data Integrity and Reliability: Storing more data in a single cell increases the risk of data errors. Sophisticated error correction codes and robust data management techniques are vital to maintain data integrity and reliability.

- Manufacturing Yield: Maintaining high yields in the production of these complex devices requires precise control at every stage. Any defect can significantly impact the overall production output.

- Cost Optimization: Balancing the need for high capacity with cost-effectiveness is a critical aspect of mass production. Finding efficient manufacturing processes and materials is crucial for making these storage solutions accessible.

- Comparison to Other Storage Devices: Traditional HDDs offer high storage capacity at a lower cost. The comparison depends on the application. SSDs, with their higher performance, are favored for applications demanding fast data access.

Market Analysis and Consumer Demand

The mass production of Samsung’s 4TB QLC SSD signifies a significant advancement in high-capacity storage. Understanding the current market landscape, target consumer base, and anticipated demand is crucial for effective pricing and marketing strategies. This analysis will dissect the trends, target demographics, and competitive comparisons to provide a clear picture of the potential success of this product.The high-capacity storage market is rapidly evolving, driven by the ever-increasing data demands of consumers and businesses alike.

Samsung’s 4TB SSD QLC storage is ramping up mass production, a promising development for affordable high-capacity storage solutions. However, it’s important to consider the broader societal impact, like the recent CDC study linking e-cigarette ad exposure to teen vaping ( e cigarette ad exposure linked to vaping among teens cdc study ). This raises important questions about responsible advertising and its potential influence on vulnerable populations, which, in turn, could affect the consumer demand for and therefore the mass production of tech like Samsung’s new storage.

Hopefully, these advancements in storage technology will be accompanied by proactive measures to ensure responsible use and minimize potential negative consequences.

Consumers are increasingly seeking larger storage capacities for multimedia content, backups, and cloud storage, driving the need for affordable and reliable solutions.

Current Market Trends for High-Capacity Storage Solutions

The high-capacity storage market is dominated by various technologies, each with its strengths and weaknesses. Solid-State Drives (SSDs) are gaining traction over traditional Hard Disk Drives (HDDs) due to their faster read/write speeds and lower power consumption. The demand for higher storage capacities in SSDs is constantly growing, reflecting the expansion of data usage across various sectors.

Target Consumer Base for the 4TB QLC SSD

This 4TB QLC SSD is aimed at a broad consumer base, including individuals and businesses. The target consumer includes content creators (photographers, videographers, gamers), professionals requiring large amounts of data storage, and users needing extensive backups. The large storage capacity makes it suitable for personal archives, business data storage, and multimedia enthusiasts.

Expected Consumer Demand for this Product

The anticipated demand for the 4TB QLC SSD is substantial, fueled by the increasing need for affordable high-capacity storage solutions. Users seeking cost-effective alternatives to higher-capacity, higher-priced TLC or PCIe Gen 4 SSDs will likely be drawn to this product. The product’s availability at a competitive price point will be a key factor in driving demand. The market for high-capacity storage has consistently shown growth, with a projected expansion in the coming years.

For example, recent industry reports indicate a steady increase in the sales of high-capacity SSDs over the past few years.

Pricing Strategy Considerations for Mass Production, Samsung 4tb ssd qlc storage mass production

The pricing strategy for the 4TB QLC SSD must consider production costs, market competition, and desired profit margins. Cost optimization throughout the manufacturing process will be critical for achieving profitability while offering a competitive price. Analysis of similar products and their pricing in the market will inform a competitive pricing strategy. Factors like economies of scale in mass production can significantly reduce the per-unit cost, impacting the final retail price.

Understanding the cost structure associated with the manufacturing process and raw material costs is vital for a viable pricing strategy.

Samsung’s 4TB SSD QLC storage is finally hitting mass production, which is great news for consumers looking for affordable high-capacity storage solutions. However, it’s important to keep in mind that while the technology is advancing, some companies, like T-Mobile, are also adjusting their plans. For instance, T-Mobile is raising rates on select legacy plans , which might affect how much you spend on your phone bill.

This shift in pricing, alongside the increased availability of affordable 4TB SSD QLC storage, could mean more options for backing up all those digital memories.

Detailed Comparison of Various Storage Options in the Market

| Storage Type | Technology | Speed | Capacity | Cost | Suitability |

|---|---|---|---|---|---|

| HDD | Magnetic platters | Slower | High (TBs) | Low | Large archival storage, large files |

| TLC SSD | 3-bit data per cell | Faster than HDD | Moderate | Moderate | General purpose storage |

| QLC SSD | 4-bit data per cell | Faster than HDD | High | Lower than TLC | Large capacity, cost-conscious consumers |

| PCIe Gen 4 SSD | Advanced interface | Very fast | Moderate to High | Higher | High performance applications |

The table above presents a concise overview of different storage options. Each technology offers distinct characteristics in terms of speed, capacity, and cost. Understanding these differences is critical in determining the most appropriate storage solution for specific needs. QLC SSDs, in particular, offer a balance between cost and capacity, making them attractive to users seeking large storage solutions without a significant price premium.

Cost Analysis and Efficiency

The mass production of Samsung’s 4TB QLC SSDs necessitates a meticulous analysis of production costs to ensure profitability and competitiveness in the market. Understanding the factors driving these costs, and identifying potential avenues for optimization, are crucial for maintaining a sustainable business model. This section delves into the estimated costs, influential factors, and strategies to achieve cost efficiency in this endeavor.The cost structure for manufacturing 4TB QLC SSDs is complex, encompassing materials, labor, research & development, factory overhead, and marketing.

Each element must be considered within the context of economies of scale as production volumes increase.

Estimated Costs of 4TB QLC SSD Production

The precise figures for the manufacturing cost of a 4TB QLC SSD are proprietary information. However, general estimations can be derived from industry trends and publicly available data. Manufacturing costs will likely vary based on factors like the specific components used, the scale of the production facility, and technological advancements. One possible estimate could be that raw materials account for a significant portion, potentially between 15% to 25% of the total cost, depending on the material price fluctuations.

Factors Influencing Production Costs

Several key factors influence the production costs of 4TB QLC SSDs. These include the cost of NAND flash memory chips, the complexity of the controller, the labor costs in the manufacturing facility, and the cost of quality control measures. Furthermore, fluctuating material prices and currency exchange rates can introduce significant volatility in the cost calculation.

Optimizing the Production Process for Cost Efficiency

Optimized production processes can significantly reduce costs. Implementing automation and streamlining assembly lines can improve efficiency and minimize labor costs. Furthermore, strategic sourcing of raw materials can help secure favorable pricing and ensure reliable supply chains. This also includes negotiating contracts with suppliers for better pricing and exploring alternative materials that offer similar performance at a lower cost.

Strategies to Reduce Production Costs and Maintain Profitability

Several strategies can help reduce production costs while maintaining profitability. These include improving the yield rate of the NAND flash memory chips, using more cost-effective packaging materials, and optimizing the manufacturing process through automation and streamlined workflows. Furthermore, efficient supply chain management and negotiation with suppliers are crucial for securing favorable pricing on raw materials.

Savings Potential of QLC Technology Compared to TLC

QLC technology, while offering higher storage capacity, presents potential cost savings compared to TLC (Triple-Level Cell) technology. This is because the manufacturing process for QLC might be less complex, leading to lower material and labor costs. However, it’s important to consider the potential for reduced write endurance in QLC compared to TLC, which could lead to higher maintenance and repair costs.

The long-term cost-benefit analysis needs to account for both initial costs and potential future repairs or replacements. This cost-effectiveness will largely depend on the balance between the reduced production costs and the anticipated need for future replacements or repairs.

Quality Control and Reliability: Samsung 4tb Ssd Qlc Storage Mass Production

Ensuring the quality and reliability of Samsung’s 4TB QLC SSDs during mass production is paramount. This involves meticulous attention to detail at every stage of the manufacturing process, from component sourcing to final testing. A robust quality control system is crucial to maintain the high standards expected by consumers and industry partners. The reliability of these SSDs is directly linked to their long-term performance and longevity.The quality control system for the 4TB QLC SSDs is multi-faceted, employing a combination of automated and manual procedures to identify and eliminate potential defects.

This comprehensive approach ensures that the final product meets the stringent performance requirements.

Quality Control Measures

The quality control process for the 4TB QLC SSDs begins with the raw material inspection. Suppliers are rigorously vetted to guarantee the quality and consistency of components. This initial step sets the foundation for the entire manufacturing process. Detailed documentation of incoming materials and processes is maintained.

- Raw Material Inspection: Incoming components, such as NAND chips, controllers, and other parts, are meticulously inspected for defects. This includes visual inspections, electrical tests, and other quality assessments to ensure compliance with specifications. Strict adherence to pre-defined quality standards ensures the integrity of the entire manufacturing process. Non-conforming materials are immediately rejected to prevent further issues.

- In-Process Testing: Continuous testing occurs at various stages of the manufacturing process. This ensures that each step aligns with the design specifications. Real-time monitoring of critical parameters and processes is critical in identifying and addressing issues promptly. For example, specific electrical characteristics are measured at critical points, and deviation from specifications is promptly corrected.

- Final Functional Testing: Each 4TB QLC SSD undergoes a comprehensive suite of functional tests. These tests simulate real-world usage scenarios, assessing factors like read/write speeds, endurance, and temperature stability. This comprehensive testing ensures the SSDs meet or exceed performance benchmarks.

Potential Risks and Defects

Several potential risks and defects can arise during the manufacturing process of QLC SSDs. These include variations in NAND chip performance, issues with controller integration, and manufacturing defects in the assembly process. Careful attention to each step minimizes these risks.

- NAND Flash Degradation: QLC NAND flash memory is more susceptible to data degradation compared to TLC or SLC. The manufacturing process must mitigate this risk. This involves optimizing the cell design, the write-scheduling algorithm, and the quality control of the raw NAND flash materials.

- Controller Errors: The controller is responsible for managing the NAND flash. Errors in the controller’s firmware or hardware can lead to data corruption or unexpected behavior. Rigorous testing and validation of the controller software and hardware is crucial.

- Assembly Defects: Issues in the assembly process, such as solder bridging or improper component placement, can lead to malfunctions. The use of automated assembly lines and advanced optical inspection systems helps identify and prevent these errors.

Reliability and Durability Measures

Reliability and durability are paramount for SSDs, especially QLC. Samsung employs advanced techniques to enhance these aspects. The use of advanced materials and manufacturing processes is vital to minimize potential defects and maximize lifespan.

- Robust Error Correction Codes (ECC): Advanced ECC algorithms are implemented to mitigate data loss due to potential errors in the NAND flash memory. This proactive measure is essential for the reliability and data integrity of the 4TB QLC SSDs. The algorithms are designed to identify and correct errors, preventing data corruption.

- Thermal Management: Effective thermal management is crucial for maintaining optimal performance and longevity. This involves the use of advanced thermal solutions, such as heat sinks and cooling systems. A thermal management system prevents overheating, which can cause irreversible damage to the SSDs.

- Wear-Leveling Techniques: Wear-leveling techniques distribute the write operations across different NAND flash cells to prolong their lifespan. This approach is critical for QLC SSDs, as it helps minimize the impact of writing on the cells. The wear-leveling algorithm ensures a more even distribution of write operations across the NAND flash memory.

Testing Procedures

A comprehensive suite of tests is performed to verify the performance and reliability of the 4TB QLC SSDs. These tests simulate various usage scenarios, stress the SSDs, and analyze their behavior under different conditions.

- Endurance Testing: Extensive endurance testing is performed to assess the SSD’s ability to handle a large number of write operations. This ensures the longevity of the device. The tests are designed to simulate real-world usage patterns, such as frequent file writing and deletion.

- Temperature Cycling: SSD performance and reliability are evaluated under various temperature conditions to ensure stable operation in different environments. This ensures optimal performance across different temperatures, guaranteeing consistency across different operating environments.

- Random Access Testing: Random access testing measures the SSD’s performance in handling random read/write operations. This is crucial to ensure the device’s efficiency in applications demanding quick access to data from various locations.

Environmental Impact and Sustainability

The mass production of any electronic component, including 4TB QLC SSDs, carries an environmental responsibility. Minimizing the impact of this manufacturing process is crucial, not just for ethical reasons, but also for long-term sustainability and responsible resource management. The environmental footprint extends beyond the manufacturing phase to encompass the entire product lifecycle, from raw material extraction to eventual disposal.

A comprehensive approach is required to mitigate negative impacts and promote a more eco-conscious approach.

Environmental Impact of Mass Production

The manufacturing process for 4TB QLC SSDs, like any electronic product, involves significant energy consumption and the use of various materials. Manufacturing facilities require substantial power for operations like refining, smelting, and assembling. Transportation of raw materials and finished goods also contributes to carbon emissions. Waste generation during the manufacturing process, including electronic waste (e-waste), must be carefully managed to prevent pollution.

This necessitates careful consideration of the entire supply chain and the potential for minimizing environmental harm at every stage.

Measures to Minimize Environmental Footprint

Several measures are implemented to reduce the environmental impact of 4TB QLC SSD production. These strategies encompass energy efficiency in manufacturing, the use of recycled materials, and the implementation of sustainable sourcing practices. Companies are increasingly prioritizing renewable energy sources to power their facilities, reducing reliance on fossil fuels. Waste reduction and recycling programs are also crucial components of minimizing the environmental impact.

A commitment to sustainable packaging materials is another key element, which involves the utilization of recycled and recyclable materials.

Sustainable Manufacturing Practices

Sustainable manufacturing practices in the electronics industry are crucial for mitigating environmental impact. These practices encompass the use of eco-friendly materials, efficient energy management systems, and waste reduction strategies. Emphasis is placed on minimizing the use of hazardous substances and promoting the use of recycled materials. Companies are also investing in advanced technologies and processes that improve energy efficiency and reduce waste.

This approach necessitates a collaborative effort between manufacturers, suppliers, and consumers to promote a circular economy.

Comparison of Storage Technologies

Different storage technologies exhibit varying environmental impacts. Hard Disk Drives (HDDs), for example, often require more energy during operation and have a higher impact on raw material extraction compared to SSDs. The manufacturing process for NAND-based SSDs, like QLC, has a significant environmental footprint, especially if not managed sustainably. The long-term impact on the environment, including energy consumption and e-waste, should be considered when evaluating the overall sustainability of different storage technologies.

Raw Materials and Sourcing Strategies

The raw materials used in 4TB QLC SSD production include various elements and compounds. The sourcing of these materials is crucial for sustainability. The environmental impact of mining and processing these materials must be considered. Responsible sourcing strategies ensure that raw materials are obtained from ethically and environmentally sound sources. This involves working with suppliers who adhere to stringent environmental standards and ethical labor practices.

Transparency in the supply chain is also crucial to ensure accountability and traceability.

Samsung’s 4TB SSD QLC storage is finally hitting mass production, which is great news for affordable high-capacity storage solutions. While I’m personally more focused on speed and efficiency, this development is definitely interesting. It’s exciting to see how this impacts the wider market, particularly when considering the broader context of productivity tools like microsoft edge sidebar widgets search email recipes for managing email and finding recipes.

Ultimately, this mass production of the 4TB SSD QLC storage will hopefully bring down prices and make high-capacity storage more accessible for everyone.

Future Outlook and Predictions

The mass production of Samsung’s 4TB QLC SSDs marks a significant milestone in the storage industry. This increased capacity, combined with anticipated improvements in performance and cost-effectiveness, opens up exciting possibilities for the future. The long-term implications for various sectors are substantial, potentially transforming how data is managed and utilized.

Potential Future Applications

The 4TB QLC SSDs, with their substantial capacity, are poised to revolutionize various sectors. In the realm of data analytics, researchers and businesses can store and process significantly larger datasets, leading to more in-depth insights and predictive modeling. This includes areas like medical research, financial modeling, and climate science, where massive datasets are critical for progress. Furthermore, the ability to store and process this data efficiently will enable the development of more sophisticated artificial intelligence models.

Video and image archives, a growing necessity for entertainment, scientific, and personal uses, will find substantial storage solutions.

Long-Term Implications of Mass Production

The mass production of 4TB QLC SSDs will drive down costs, making high-capacity storage more accessible to consumers and businesses. This accessibility will fuel the growth of cloud storage services, as users and businesses will be incentivized to store more data off-site. Moreover, the economies of scale inherent in mass production will encourage the development of new, innovative storage solutions.

This includes a wider range of devices, such as embedded systems in automobiles, industrial automation, and smart home appliances, all requiring high storage capacities.

Future Developments in the Storage Industry

The storage industry is constantly evolving. Future developments will likely focus on further improving QLC technology, potentially introducing more advanced NAND flash memory architectures. We can also anticipate a surge in hybrid storage solutions combining different technologies like QLC SSDs with NVMe or SATA drives to balance performance and capacity. Additionally, the emergence of new storage protocols and interfaces, like PCIe Gen 5 and NVMe 2.0, will significantly impact the speed and efficiency of data transfer.

Impact on Various Sectors

The widespread adoption of 4TB QLC SSDs will have a profound impact across sectors. In the gaming industry, larger game installations and more complex simulations will become feasible. Businesses will be able to store and manage their data more efficiently, leading to improved operational efficiency and potentially lower costs. In the scientific community, larger datasets will accelerate research in various fields, leading to breakthroughs in medicine, materials science, and more.

Summary of Future Trends in SSD Technology

| Technology | Capacity | Speed | Cost |

|---|---|---|---|

| QLC SSDs | Increasing (potentially exceeding 8TB) | Improvements expected through refined technology | Decreasing due to mass production |

| Hybrid Storage Solutions | Balancing high capacity and performance | Optimized performance through various drive combinations | Competitive cost, dependent on the specific combination |

| New Storage Protocols | High capacity, high performance | Significant increase in speed (e.g., PCIe Gen 5) | Initially higher, but expected to decrease over time |

Competitive Landscape and Differentiation

The 4TB QLC SSD market is a fiercely contested arena. Samsung, a leader in semiconductor technology, faces stiff competition from established players and emerging startups. Understanding the competitive landscape, identifying key differentiators, and analyzing Samsung’s strategies are crucial to assessing its potential success. This section will delve into the competitive landscape, comparing Samsung’s 4TB QLC SSD to key competitors.

Competitive Landscape Analysis

The storage market is dynamic, with a constant push for higher capacity, faster speeds, and lower costs. Existing competitors like Seagate, WD, and Crucial are well-established players with extensive production capabilities and distribution networks. Emerging companies, with innovative technologies, are also vying for market share. This competitive landscape demands that Samsung not only maintain its technological edge but also effectively position its 4TB QLC SSD against rivals.

Key Differentiators and Advantages

Samsung’s strengths in manufacturing processes, quality control, and technological innovation are key differentiators. Their advanced QLC (Quad-Level Cell) NAND flash technology enables higher storage density at a lower cost compared to TLC (Triple-Level Cell). This, coupled with their proven track record in producing high-performing SSDs, puts them in a strong position. Moreover, Samsung’s commitment to research and development ensures they remain ahead of the curve in future technological advancements.

Comparison of Samsung 4TB QLC SSD with Competitors

| Feature | Samsung 4TB QLC | Competitor A (e.g., Seagate) | Competitor B (e.g., WD) |

|---|---|---|---|

| NAND Flash Technology | QLC | TLC | TLC |

| Storage Capacity | 4TB | 4TB (possibly TLC-based) | 4TB (possibly TLC-based) |

| Sequential Read Speed (MB/s) | >500 (estimated, varies by model) | ~400-500 (estimated, varies by model) | ~400-500 (estimated, varies by model) |

| Sequential Write Speed (MB/s) | >300 (estimated, varies by model) | ~250-350 (estimated, varies by model) | ~250-350 (estimated, varies by model) |

| Random Read/Write Performance | Moderate, trade-off for capacity and cost | Higher than QLC, but lower than some higher-end models | Higher than QLC, but lower than some higher-end models |

| Pricing | Competitive, potentially lower than comparable TLC models | Competitive, possibly slightly higher than Samsung due to TLC | Competitive, possibly slightly higher than Samsung due to TLC |

| Reliability | Industry-leading, with ongoing testing and quality control | Strong reputation for reliability, but QLC reliability is a factor | Strong reputation for reliability, but QLC reliability is a factor |

Note: Specific performance figures are estimates and may vary based on specific model configurations. Competitor specifications are estimated and not precise. Reliability data is based on industry standards and ongoing testing.

Samsung’s Competitive Strategies

Samsung employs a multi-faceted approach to differentiate its 4TB QLC SSD. They focus on optimizing the QLC technology for performance and reliability, balancing cost-effectiveness with consumer needs. Aggressive pricing strategies and a strong distribution network are also key components of their approach. Furthermore, continuous innovation in manufacturing processes and materials contributes to long-term competitiveness.

Ending Remarks

In conclusion, Samsung’s 4TB QLC SSD mass production represents a significant leap forward in storage technology. The potential for lower costs, increased capacity, and wider accessibility is enormous. However, challenges in manufacturing, maintaining quality, and navigating the competitive landscape will be crucial to success. The future of storage looks bright, and this project is a key part of that future.