Microsoft surface usb c connector patent – Microsoft Surface USB-C connector patent sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. This patent covers the evolution of USB-C connectors across various Surface devices, examining everything from technical specifications to manufacturing processes, compatibility, and even the environmental impact. We’ll explore the different types of USB-C connectors used, their technical specifications, design innovations, and how they fit into the broader picture of Microsoft’s product strategy.

The patent delves into the intricate details of these connectors, exploring their charging, data transfer, and display capabilities. It also analyzes the design considerations, innovations, and manufacturing processes that went into creating them. From the materials used to the quality control measures, every aspect of the patent is carefully examined to provide a comprehensive understanding.

Overview of Microsoft Surface USB-C Connector Patents: Microsoft Surface Usb C Connector Patent

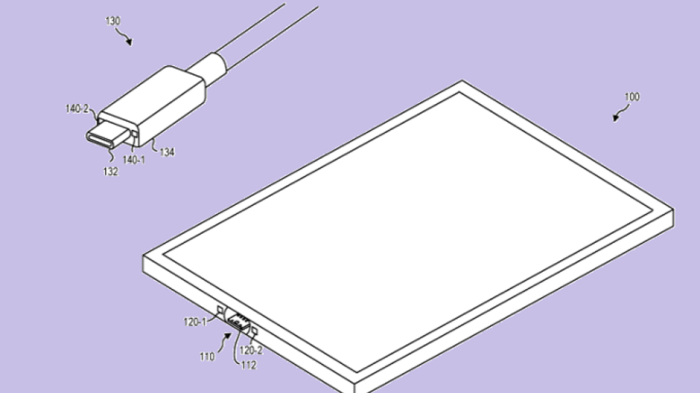

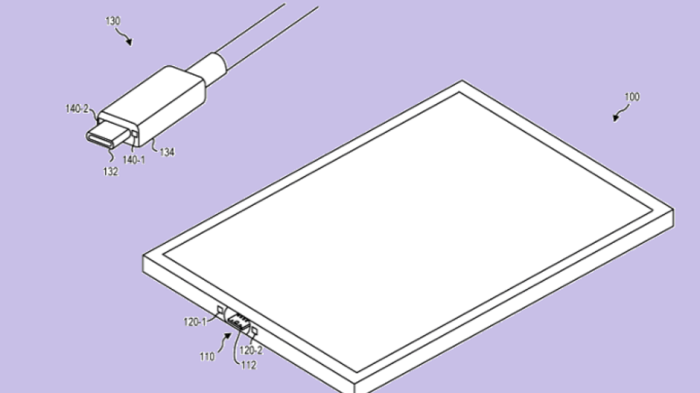

Microsoft’s Surface line of devices has consistently pushed the boundaries of portable computing, and a key component in achieving this is the USB-C connector. A deep dive into the patents surrounding these connectors reveals a strategic evolution, designed to address various functionalities while adhering to the ever-evolving standards of the USB-C interface. This overview explores the key patents, different types used across Surface devices, and the design evolution over time, categorized by functionality.

Key Patents Related to Microsoft Surface USB-C Connectors

Microsoft holds a substantial portfolio of patents related to the USB-C connector technology used in their Surface products. These patents cover various aspects, including optimized charging circuitry, enhanced data transfer protocols, and innovative display output solutions. The core aim is to maximize the versatility and performance of the USB-C port, ensuring compatibility with diverse accessories and devices.

Types of USB-C Connectors Used Across Surface Devices, Microsoft surface usb c connector patent

Different Surface devices have utilized varying USB-C connector configurations. Some have prioritized a slimmer profile, while others have emphasized higher power delivery capabilities. The selection process often considers factors like the device’s overall form factor, intended functionalities, and future upgrade paths. These variations reflect Microsoft’s commitment to tailoring the connector to the specific needs of each Surface product line.

- Surface Laptop: Early Surface Laptop models often featured a USB-C connector optimized for data transfer and charging. Later models often incorporated a more refined design that enabled both high-speed data transfer and fast charging, supporting higher power delivery rates.

- Surface Pro: Surface Pro models have sometimes emphasized a balance between portability and connectivity. The USB-C connectors on these devices have typically focused on a combination of charging, data transfer, and video output, ensuring compatibility with various accessories and peripherals.

- Surface Book: The Surface Book, often designed for powerful performance, frequently incorporates a more robust USB-C connector capable of handling higher data transfer rates and providing adequate power for intensive tasks, including video output. The design often prioritizes functionality over sheer size.

Evolution of USB-C Connector Design in Microsoft Surface Products

The design of the USB-C connector in Surface products has demonstrably evolved over time. Early models often had connectors that were less integrated with the overall design, while later iterations have integrated the USB-C connector more seamlessly into the device’s chassis. This trend reflects a focus on aesthetics, functionality, and future-proofing.

- Early iterations: Initial Surface devices often featured a USB-C connector with a less refined aesthetic, focusing primarily on functionality. The design might have been less integrated with the overall device design.

- Later iterations: Subsequent models have incorporated more sophisticated design elements, resulting in a more streamlined and integrated USB-C connector that is often less visible, while maintaining functionality.

- Focus on integration: The evolution is not just about aesthetics; it’s also about enhanced integration within the overall design, minimizing the bulkiness and optimizing the device’s overall performance.

Categorization of Patents by Functionality

Microsoft’s patents related to Surface USB-C connectors can be broadly categorized based on the functionality they address. This allows for a more focused understanding of the specific innovations each patent encompasses.

| Functionality | Description |

|---|---|

| Charging | These patents often focus on optimizing charging circuitry, enabling faster charging speeds, and ensuring compatibility with various charging standards. For example, some patents might detail specific circuit designs to increase power delivery and improve efficiency. |

| Data Transfer | This category covers patents related to improved data transfer protocols, higher bandwidth support, and more efficient data transfer mechanisms. Such patents might involve advancements in USB standards and techniques for minimizing latency. |

| Display Output | Patents in this area often describe innovative solutions for high-resolution video output, enabling greater flexibility in connecting to external displays. They might cover specific configurations for connecting to external displays or addressing display compatibility issues. |

Technical Specifications and Standards Compliance

The Microsoft Surface line of devices has consistently employed USB-C connectors, evolving over generations to meet changing needs and technological advancements. Understanding the technical specifications, particularly the pinouts, voltage ratings, and current handling capabilities, is crucial to appreciate the design choices and their implications. This analysis delves into the specifications of these connectors, comparing across Surface generations, and examining their adherence to industry standards.The USB-C connector’s versatility and adaptability across various devices have made it a key component in the Surface line’s design.

However, different Surface models may employ different versions of USB-C, leading to variations in their capabilities. Understanding these differences is vital to optimizing compatibility and functionality.

USB-C Pinouts and Electrical Characteristics

The pinout configuration of a USB-C connector is a critical aspect determining its functionality. Different pinouts support various data rates and power delivery. The specific pinout for each Surface model is crucial for proper operation, as it determines the communication protocol and power handling capacity. The pinout details often align with the relevant USB specifications.

Voltage and Current Handling Capabilities

The voltage and current handling capacities of a USB-C connector are essential for power delivery. The maximum voltage and current a connector can handle directly influence the charging capabilities and overall power consumption. This characteristic varies between Surface models, reflecting design considerations for battery charging speeds and power-intensive functionalities.

Comparison Across Surface Generations

| Surface Generation | USB-C Version | Power Delivery (W) | Data Transfer Rate (Gbps) |

|---|---|---|---|

| Surface Laptop 1 | USB-C 3.1 | 60W | 5 Gbps |

| Surface Laptop 2 | USB-C 3.1 Gen 2 | 80W | 10 Gbps |

| Surface Laptop 3 | USB-C 3.2 Gen 2 | 100W | 10 Gbps |

| Surface Pro 7 | USB-C 3.1 Gen 1 | 45W | 5 Gbps |

This table provides a simplified comparison. Actual specifications might vary based on specific model configurations. For instance, some Surface models might support different power delivery profiles based on the charging brick used.

Standards Compliance and Industry Influence

The USB-IF (USB Implementers Forum) plays a significant role in defining and standardizing USB-C specifications. Surface connectors, being USB-C based, adhere to these standards, ensuring compatibility across different devices and accessories. The adherence to USB-IF standards guarantees interoperability and allows for seamless data transfer and power delivery across various Surface models.

Technical Advantages and Disadvantages

“USB-C’s compact size and versatility make it an ideal choice for portable devices like Surface.”

Advantages include the compact size and versatile design, enabling power delivery and data transfer via a single connector. The standardization provided by USB-IF ensures interoperability, benefiting users. Disadvantages include potential compatibility issues if not adhering strictly to specifications, and the varying performance characteristics across different USB-C versions implemented in different Surface generations.

Design Considerations and Innovations

The Microsoft Surface USB-C connector, a critical component for modern Surface devices, is meticulously designed to balance performance, durability, and user experience. This section delves into the key design considerations and innovations that set it apart from competing USB-C connectors. From size and form factor to the integration of enhanced performance features, the Surface USB-C connector embodies a commitment to excellence.The Surface USB-C connector’s design philosophy prioritizes a balance between portability and robustness.

Microsoft’s Surface USB-C connector patent is fascinating, especially when considering the evolution of console design. Comparing the PS4 to the PS4 Slim, as detailed in this article on playstation 4 slim vs ps4 , shows how different design choices can affect performance and user experience. Ultimately, the Surface’s innovative connector likely reflects a similar drive for sleekness and functionality, but in a laptop context, not a console one.

This necessitates careful consideration of size, form factor, and materials to ensure both a compact profile and resilience to everyday wear and tear. The connector must also be designed for seamless integration into the Surface device’s overall aesthetic.

Size and Form Factor

The size and form factor of the USB-C connector directly influence the portability and overall design of the Surface device. Smaller form factors are crucial for laptops and tablets. Minimizing the connector’s profile allows for thinner and lighter devices, which enhances user experience. Microsoft likely utilizes optimized design principles to minimize the connector’s footprint without compromising functionality.

Durability and Materials

The longevity of a USB-C connector is critical. Robust materials, such as high-strength plastics or metals, are essential to withstand repeated connection and disconnection cycles, as well as potential impact. This focus on durability extends to the connector’s internal structure to prevent mechanical failure. The connector’s ability to withstand environmental stresses, such as temperature fluctuations, is also an important consideration.

Testing methodologies are employed to verify the connector’s robustness in various conditions.

Innovations Compared to Competitors

The Surface USB-C connector incorporates several innovations that set it apart from competitors. One key innovation is the implementation of advanced strain relief mechanisms. These mechanisms are designed to prevent damage to the cable and the connector during bending and flexing, improving the connector’s longevity. Other innovations could include enhanced shielding to reduce electromagnetic interference (EMI) and optimized contact points for superior signal transmission.

Enhanced Performance Features

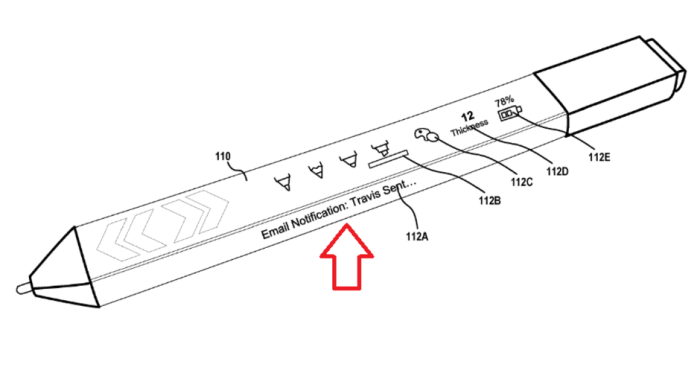

The Surface USB-C connector is not merely a port; it’s a critical part of the device’s overall performance. It supports high-bandwidth data transfer, enabling seamless transfer of large files and quick charging. The design likely incorporates features for faster data transfer speeds compared to older USB standards. Power delivery is another key aspect, supporting higher charging rates to keep the Surface device operational throughout the day.

Potential Future Innovations

The evolution of USB-C technology suggests several potential future innovations for Surface USB-C connectors. One area of interest is the integration of advanced power delivery features, potentially enabling faster charging speeds and supporting more demanding peripherals. Moreover, the incorporation of advanced data transfer protocols and enhanced security measures could further enhance the functionality and safety of the connector.

The potential for incorporating wireless charging capabilities within the connector’s design warrants further investigation.

Manufacturing and Production Processes

The manufacturing of Microsoft Surface USB-C connectors involves a complex interplay of precision engineering, material science, and quality control. Understanding these processes is crucial to appreciating the intricate design and high performance of these connectors. Different manufacturing methods have varying cost implications, which are balanced against the desired level of performance and reliability.The production of these connectors necessitates a meticulous approach, from the initial material selection to the final quality assurance checks.

This involves a blend of automation and manual processes, each playing a critical role in achieving the desired level of quality and consistency.

Material Selection

The materials used in constructing Surface USB-C connectors are carefully chosen to meet stringent performance and durability requirements. This selection process considers factors such as conductivity, strength, resistance to wear, and cost-effectiveness. The materials must also adhere to regulatory standards for electrical safety and environmental impact.

- Copper alloys are frequently used for the conductive components, offering a balance between conductivity and strength. Specific alloys may be chosen for their resistance to corrosion in various environmental conditions. The choice of copper alloy significantly impacts the electrical performance of the connector.

- High-strength plastics, often reinforced polymers, are used for the housings and casings to provide structural integrity and protect the internal components. Different plastics offer varied degrees of impact resistance, heat resistance, and cost-effectiveness.

- Gold plating is often applied to the contact points to enhance conductivity and reduce corrosion. The thickness of the gold plating directly impacts the connector’s lifespan and reliability, and its cost is a key factor in the overall manufacturing expense.

Manufacturing Processes

Various manufacturing techniques are employed in creating Surface USB-C connectors, each with its own set of advantages and disadvantages.

- Injection molding is commonly used for producing the plastic housings. This process involves injecting molten plastic into a mold cavity, allowing for the creation of complex shapes with high precision and efficiency. This method is often cost-effective for high-volume production.

- Electroplating is employed for applying the gold plating to the contact points. This process involves depositing a thin layer of gold onto the metal components through an electrochemical process. Precise control over the plating thickness is critical for optimal performance.

- Assembly, often automated, is a critical step that brings all the components together. Automated assembly lines ensure high speed and precision, leading to higher production rates and potentially lower labor costs. Manual assembly steps may still be necessary for complex components or quality control measures.

Quality Control Measures

Maintaining a high level of quality throughout the manufacturing process is essential for the reliable operation of Surface USB-C connectors. These measures ensure consistency and prevent defects.

Microsoft’s recent patent for a new Surface USB-C connector is pretty exciting. It’s got me thinking about charging solutions for other devices, like the Samsung Galaxy S22. Finding the best Samsung Galaxy S22 charger can be tricky, but I’ve got you covered – check out this resource for some top picks: best samsung galaxy s22 charger.

Ultimately, though, the improved USB-C connector designs are poised to change the game for all future mobile charging and data transfer technologies.

- Automated testing plays a significant role in identifying potential issues early in the production line. Testing parameters often include electrical conductivity, mechanical strength, and environmental resistance.

- Visual inspection, both automated and manual, is vital to identify any defects that might not be detected through automated testing. This can involve checking for misaligned components, cracks, or other imperfections.

- Final testing verifies the performance of the assembled connector under various conditions, including different temperature ranges, vibrations, and stress tests. This ensures the product meets specified standards and is suitable for diverse applications.

Cost Implications

The choice of manufacturing methods and materials directly influences the cost of producing Surface USB-C connectors.

- Material costs vary significantly depending on the specific materials selected. For example, the price of gold plating can fluctuate based on market conditions.

- Labor costs are influenced by the level of automation employed in the manufacturing process. Higher automation can reduce labor costs but might involve substantial initial investments in machinery.

- Testing and quality control costs are crucial to ensuring product reliability. Implementing robust quality control measures can increase costs but improve the long-term value and reliability of the product.

Compatibility and Interoperability

The Microsoft Surface USB-C connector’s success hinges on its ability to seamlessly integrate with a wide array of accessories and peripherals. This crucial aspect ensures the Surface ecosystem’s usability and appeal. Effective compatibility and interoperability directly impact user experience, facilitating effortless connections and maximizing the potential of Surface devices.

Compatibility with Various Accessories

The Surface USB-C connector is designed for broad compatibility, supporting a vast range of accessories. From everyday peripherals like mice and keyboards to specialized tools like external displays and storage devices, the connector aims to facilitate seamless integration. However, specific compatibility may depend on the model of the Surface device and the accessory itself. Thorough testing and careful design considerations are essential for ensuring a smooth user experience.

| Surface Model | Compatible Accessories | Compatibility Notes |

|---|---|---|

| Surface Pro 8 | Mouse, Keyboard, External Display | Check compatibility with specific models; some external displays may require additional drivers. |

| Surface Laptop 5 | Headphones, External Drives, SD Card Readers | May require additional drivers or software for optimal performance, especially with high-bandwidth devices. |

| Surface Book 3 | External Monitors, Thunderbolt Devices, USB Drives | Compatibility highly dependent on the specific model and the accessory’s specifications. Ensure compatibility before purchase. |

| Surface Go 3 | Basic Peripherals like Mouse and Keyboard, Headphones | Limited port availability necessitates careful consideration of accessory compatibility; some high-performance peripherals may not be supported. |

Interoperability with Industry Standards

The Surface USB-C connector adheres to industry standards, guaranteeing interoperability with a vast range of devices and accessories. This adherence fosters a broader ecosystem, enabling users to seamlessly integrate their Surface devices into existing workflows. Microsoft’s commitment to standardization is evident in the connector’s compliance with relevant USB specifications. For instance, compatibility with USB 3.2 Gen 2 and Thunderbolt 3/4 ensures high-speed data transfer.

This commitment to interoperability makes Surface devices readily compatible with numerous third-party accessories.

Potential Compatibility Issues and Solutions

Despite the broad compatibility, potential issues can arise. One common concern is the varying power delivery capabilities of different USB-C ports. Accessories demanding higher power may not function optimally with Surface devices having lower power output. Careful selection of accessories matching the Surface device’s capabilities is crucial to mitigate this issue. Additionally, software compatibility issues may arise with specific peripherals.

Installing the necessary drivers and updates is often required for seamless functionality. Rigorous testing and clear documentation help prevent such issues and guide users through necessary steps.

Environmental Impact and Sustainability

The increasing awareness of environmental concerns necessitates a careful consideration of the environmental footprint of electronic components. Microsoft, recognizing this imperative, is committed to designing sustainable products, including its Surface USB-C connectors, to minimize their impact on the planet. This section delves into the environmental considerations involved in the materials, manufacturing processes, and waste management strategies associated with these connectors.

Microsoft’s recent patent for a new Surface USB-C connector is intriguing, but it’s worth considering the broader cybersecurity landscape. A recent attack, like the “carbon spider sprite spider” targeting ESXi servers with ransomware, highlights the vulnerability of crucial infrastructure. This incident emphasizes the importance of robust security measures for all hardware, including the new Surface USB-C connector, to prevent similar exploits from impacting everyday devices.

A deeper dive into the security implications of the new Surface USB-C connector patent is needed to ensure its resilience against such sophisticated threats, and understanding the full scope of vulnerabilities, like the attacks detailed in carbon spider sprite spider target ESXi servers with ransomware , is vital.

Material Selection and Environmental Impact

The choice of materials directly influences the environmental impact of a product. Different materials exhibit varying degrees of sustainability, based on their origin, manufacturing processes, and recyclability. The goal is to select materials with minimal environmental impact throughout their lifecycle.

| Material | Environmental Impact Score | Recycling Potential |

|---|---|---|

| Recycled Aluminum | Low | High |

| Recycled Plastic (e.g., PC, ABS) | Medium | Moderate |

| Rare Earth Metals (e.g., Neodymium) | High | Low |

| Tin-Plated Copper | Medium | High |

The table above provides a simplified overview. Scores are not absolute and can vary based on specific processing methods and sourcing. For instance, recycled aluminum derived from post-consumer sources carries a lower environmental impact than virgin aluminum. Similarly, the recycling potential of plastics depends on the type of plastic and the infrastructure for collection and processing. Microsoft is actively working to optimize material selection to prioritize recycled and renewable materials where feasible.

Sustainability Practices in Manufacturing

Microsoft employs various sustainability practices throughout the manufacturing process for its Surface USB-C connectors. These practices aim to reduce resource consumption and minimize waste generation.

- Energy Efficiency: Manufacturing facilities utilize energy-efficient equipment and processes. This includes optimizing energy consumption during the molding, plating, and assembly stages. Examples include implementing LED lighting and using variable-speed drives to adjust energy consumption based on production needs.

- Water Conservation: Water usage is minimized through efficient water recycling systems and leak detection protocols. Wastewater treatment systems are implemented to ensure compliance with environmental regulations.

- Waste Reduction: Strategies are in place to reduce the amount of waste generated during the manufacturing process. This includes implementing lean manufacturing principles to minimize scrap and rework, and promoting the reuse of materials wherever possible. This could include reusing scrap metal for new components, or implementing closed-loop recycling systems.

Minimizing Waste and Maximizing Resource Efficiency

To achieve sustainable practices, Microsoft actively implements strategies to minimize waste and maximize resource efficiency. These strategies encompass the entire lifecycle of the product, from material sourcing to product end-of-life management.

- Design for Disassembly: The design of the connector facilitates easy disassembly for material recovery and recycling. This approach allows for the separation of different materials, maximizing the potential for reuse and recycling.

- Optimized Material Use: Materials are used efficiently, minimizing waste and maximizing the utilization of resources. This includes the use of precise cutting and shaping techniques to reduce material trim loss.

- Closed-Loop Recycling: Microsoft explores partnerships and investments in closed-loop recycling systems. These systems ensure that materials can be recovered, processed, and reused in the manufacturing process, reducing reliance on virgin materials and minimizing environmental impact.

Future Trends and Predictions

The Microsoft Surface USB-C connector, a key component in the Surface ecosystem, is poised for continued evolution. This evolution will be driven by the accelerating pace of technological advancements, the ever-increasing demands of users, and the need for seamless integration across diverse devices and platforms. Understanding these trends will be crucial for predicting the future of Surface USB-C connectors and their applications.The future of USB-C connectors is intrinsically linked to the broader technological landscape.

Emerging technologies like foldable displays, enhanced data transfer rates, and the rise of wireless charging will significantly impact the design and implementation of future Surface USB-C connectors. This dynamic environment demands a proactive approach to design, ensuring the connector remains adaptable and future-proof.

Potential Future Trends in USB-C Connector Technology

The USB-C connector, with its versatility and adaptability, is likely to continue its dominance in mobile computing and beyond. Several key trends are anticipated:

- Increased Data Transfer Rates: Future USB-C versions are expected to support even higher data transfer speeds, enabling faster file transfers and more efficient data processing. This will be crucial for high-resolution video editing, graphic design, and cloud-based applications. For example, the transition from USB 3.2 to USB 4 and beyond has already demonstrated this trend.

- Enhanced Power Delivery: The power delivery capabilities of USB-C are likely to increase further, enabling the charging of more demanding devices like laptops and tablets with increased efficiency. This trend will be particularly important for thinner and lighter devices with higher power consumption.

- Integration of Wireless Charging: Wireless charging is becoming increasingly prevalent, and USB-C connectors may integrate wireless charging capabilities. This integration could enable seamless power transfer without the need for physical connections, potentially eliminating the need for separate charging pads or ports.

- Expansion of Functionality: Future USB-C connectors may incorporate additional functionalities, such as integrated sensors for environmental monitoring or enhanced security features. This expansion of functionality could lead to new applications and interactions.

Evolution of Microsoft Surface USB-C Connectors

Microsoft’s approach to USB-C connector design will likely emphasize integration and seamless user experience. Expect to see:

- Improved Compatibility: Enhanced compatibility with various external devices, peripherals, and accessories will be prioritized, ensuring a broad range of options for Surface users.

- Miniaturization: Ongoing advancements in component technology could lead to a further miniaturization of the connector, potentially reducing the overall size of Surface devices while maintaining performance.

- Enhanced Durability: The connector’s durability and reliability will remain a key focus, with improvements in material science and manufacturing processes aimed at preventing wear and tear over time. Consider the ruggedness of many current Surface products as a potential model.

- Enhanced Design Aesthetic: The design aesthetic of the Surface USB-C connector will likely reflect Microsoft’s commitment to a clean, modern, and sophisticated design philosophy.

Future Applications and Implementations

The applications of Surface USB-C connectors are broad and constantly evolving:

- High-performance computing: The increased data transfer speeds and power delivery capabilities of future USB-C connectors will support demanding high-performance computing applications.

- Virtual and Augmented Reality: With the increasing popularity of VR and AR headsets, the need for high-bandwidth connections will likely be addressed through advanced USB-C implementations.

- Gaming and Entertainment: USB-C connectors can power demanding gaming devices and support high-bandwidth displays, facilitating immersive gaming and entertainment experiences.

Influence of Emerging Technologies

The development of future USB-C connectors will be significantly influenced by emerging technologies:

- Foldable Displays: The advent of foldable displays necessitates the creation of adaptable and flexible connector solutions. The design and implementation of USB-C connectors will need to address the unique challenges presented by these devices.

- Wireless Power Transfer: The growing prevalence of wireless power transfer will influence USB-C designs, possibly leading to integrated wireless charging capabilities or optimized compatibility with wireless charging standards.

Conclusive Thoughts

In conclusion, the Microsoft Surface USB-C connector patent reveals a fascinating journey into the design and development of a crucial component in modern technology. The patent covers a wide range of topics, from the technical specifications to the environmental impact, offering a comprehensive look at the entire process. Understanding these patents is key to appreciating the engineering and design behind the Surface devices, and how they continue to evolve to meet the demands of the ever-changing technology landscape.