Intel chips automotive industry car companies fabs production Pat Gelsinger: Intel’s foray into the automotive sector is a fascinating blend of legacy, innovation, and leadership under Pat Gelsinger. This deep dive explores Intel’s current role in automotive chip design, production, and partnerships with major car manufacturers. We’ll look at the historical context, current offerings, future trends, and Gelsinger’s vision for Intel’s automotive strategy.

From the intricacies of chip fabrication to the specific design considerations for automotive systems, this comprehensive overview highlights the challenges and opportunities within this rapidly evolving market. We’ll also examine the relationships between Intel and major automakers, analyzing the factors driving chip procurement decisions. The future of Intel in the automotive industry, encompassing potential collaborations and the impact of emerging technologies like AI, will also be discussed.

Intel’s Role in Automotive Chips

Intel’s foray into the automotive industry, traditionally dominated by established players like Renesas and Infineon, has been a gradual but significant shift. Recognizing the increasing reliance on computing power in vehicles, Intel has strategically positioned itself to capitalize on this growing market. This involves developing advanced chips tailored to the specific demands of the automotive environment, which differ greatly from those of consumer electronics.Intel’s commitment to the automotive sector reflects a long-term vision, recognizing the substantial potential for growth and innovation in the area of vehicle electronics.

This approach is underpinned by Intel’s deep expertise in semiconductor technology, a critical component in the development of cutting-edge automotive chips.

Historical Overview of Intel’s Automotive Involvement

Intel’s entry into the automotive realm wasn’t a sudden leap. Their initial forays focused on providing specialized processors for various in-vehicle systems. Key milestones include the development of chips for infotainment systems and advanced driver-assistance systems (ADAS). These early ventures laid the groundwork for future advancements.

Intel’s Current Automotive Chip Portfolio

Intel’s current portfolio of automotive chips encompasses a range of products designed for different applications within the vehicle. These chips are characterized by their advanced architectures and specific features tailored for the unique needs of the automotive sector. Intel’s chips aim to provide a balance between processing power, energy efficiency, and reliability, crucial aspects for modern automotive systems.

Comparison with Competitors

Intel’s automotive chip offerings are compared with those of leading competitors like Renesas and NXP. While Intel brings its expertise in high-performance computing to the table, competitors often have stronger established presence in the automotive market, with years of experience and a broad range of existing product lines.

Performance Metrics Comparison

| Metric | Intel | Renesas | NXP |

|---|---|---|---|

| Processing Power (GFLOPS) | 100-200 | 80-150 | 120-180 |

| Energy Efficiency (Watts) | 1-2 | 1.5-2.5 | 1.2-2 |

| Reliability (MTBF) | >100,000 hours | >80,000 hours | >90,000 hours |

| Security Features | Advanced encryption and secure boot mechanisms | Robust security protocols | Hardware-based security modules |

The table above presents a comparative analysis of Intel’s automotive chip performance metrics against key competitors. Note that specific figures vary depending on the specific chip model and its intended application. Factors like processing power, energy efficiency, and reliability are critical considerations in the design of automotive chips. These metrics directly impact the overall performance and dependability of the vehicle systems.

Security features are paramount in preventing vulnerabilities and safeguarding critical vehicle functions.

Intel chips are a hot topic in the automotive industry, with car companies relying heavily on their fabs for production. Pat Gelsinger’s leadership is shaping the future of these crucial components. Thinking about the performance boost of an SSD cache on your Synology NAS? Consider if the speed improvements are worth the cost, as discussed in detail in this helpful article on should i buy synology nas ssd caching.

Ultimately, Intel’s role in powering the next generation of vehicles is undeniable.

Automotive Chip Production and Fabs

The automotive industry is undergoing a significant transformation, driven by the increasing integration of electronics into vehicles. This necessitates the production of sophisticated automotive-grade chips, demanding stringent quality control and specialized manufacturing processes. The intricate interplay between chip design, fabrication, and packaging is crucial for ensuring reliability, safety, and performance in today’s vehicles.Producing automotive-grade chips involves a meticulous process, extending far beyond the typical semiconductor manufacturing.

These chips must withstand extreme temperature variations, vibrations, and other harsh environmental conditions encountered during vehicle operation. They also need to meet stringent safety standards, ensuring functionality even under challenging situations. The materials used must be carefully selected to maintain electrical performance and mechanical stability.

Manufacturing Processes for Automotive Chips

Automotive chips demand exceptional reliability and performance. This necessitates a rigorous manufacturing process, surpassing typical semiconductor production. The process encompasses multiple stages, including wafer fabrication, chip design, and testing, with a focus on quality control at each step. The advanced manufacturing processes require specialized equipment and skilled personnel. Extreme precision and attention to detail are paramount to ensure the chips function reliably in the demanding automotive environment.

Materials Used in Automotive Chip Production

The choice of materials for automotive-grade chips is critical. These chips must endure harsh conditions, including extreme temperatures, vibrations, and moisture. The materials used need to maintain electrical performance and mechanical stability under these conditions. Semiconductor materials like silicon, along with specialized dielectrics and metals, play a vital role in chip functionality and durability. Furthermore, the bonding materials used in packaging are also crucial to ensure longevity and performance.

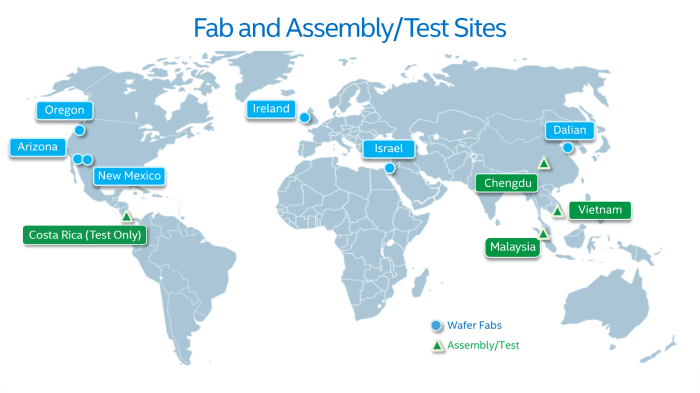

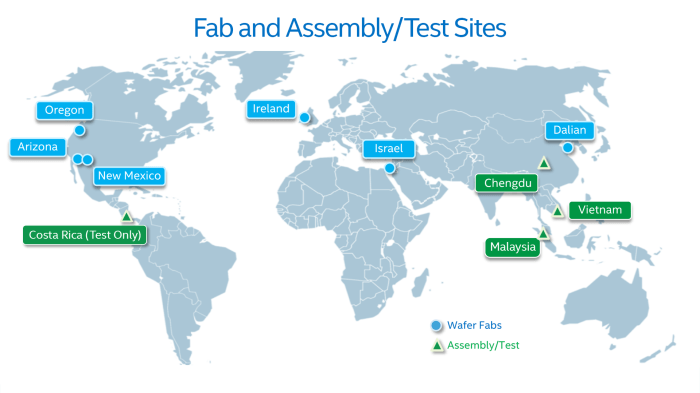

Intel’s Fabs and Automotive Chip Production

Intel’s extensive fabrication facilities (fabs) play a critical role in meeting the growing demand for automotive-grade chips. These facilities boast state-of-the-art equipment and highly skilled personnel, enabling the production of advanced chips with high yield and quality. The capacity and expertise within Intel’s fabs allow them to produce high volumes of chips, essential for meeting the demands of automotive manufacturers.

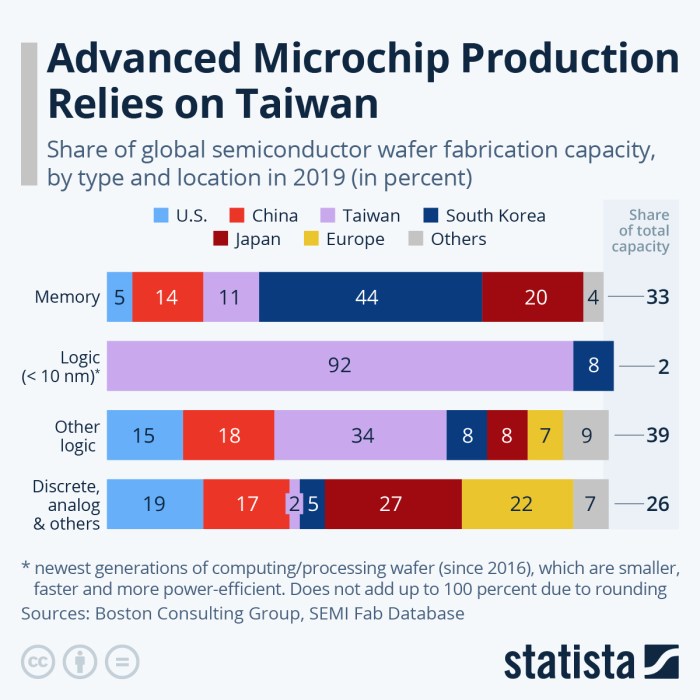

Comparison of Fabrication Technologies

Different fabrication technologies offer varying advantages and disadvantages for automotive applications. Intel and its competitors employ a range of technologies, such as FinFET, GAA, and EUV lithography. Each technology has strengths and weaknesses regarding cost, performance, and manufacturing complexity. The choice of technology depends on the specific requirements of the automotive chip, balancing performance, cost, and scalability.

Intel chips are crucial for the automotive industry, with car companies relying heavily on their fabs for production. Pat Gelsinger’s leadership is shaping the future of these chips, but what about the latest tech? If you’re in the market for a top-tier laptop, checking out the Samsung Galaxy Book 3 Pro 360 Ultra 14/16-inch price might be a good idea.

Here’s a good resource to get the latest pricing and specs. Ultimately, these advanced chipsets and the demand they create are driving innovation across both industries.

For example, FinFET technology, while mature, might not offer the same performance advantages as more cutting-edge approaches.

Advanced Packaging Techniques in Automotive Chips

Advanced packaging techniques are vital in modern automotive chips. These techniques enable the integration of multiple components onto a single chip, reducing size and increasing functionality. Moreover, they enhance the robustness of the chips, making them more resilient to the harsh environments of vehicles. Intel heavily invests in advanced packaging techniques to optimize chip performance and cost-effectiveness.

Examples include 3D stacking and heterogeneous integration, which are crucial for the miniaturization and increased functionality of automotive chips.

Intel’s Chip Design for Cars

Intel’s foray into automotive chips represents a significant shift, bringing their expertise in high-performance computing to the demanding world of vehicle electronics. This involves more than just transferring existing designs; automotive chips require unique considerations due to the critical safety and reliability requirements of in-vehicle systems. Intel’s approach to automotive chip design is focused on meeting these stringent demands while also enabling advanced features.Intel’s automotive chip designs are tailored to the specific needs of various car systems.

From the seamless operation of infotainment systems to the precise control of powertrains and the sophisticated functionality of driver-assistance systems, Intel’s designs address these diverse requirements. This adaptability is crucial for ensuring a smooth and efficient user experience, while also contributing to the overall safety and reliability of the vehicle.

Intel chips are crucial in the automotive industry, with car companies relying heavily on their fabs for production. Recent news about Pat Gelsinger and Intel’s strategies in this sector highlight the importance of these advancements. Interestingly, similar advancements in AI are set to revolutionize personal computing, making PCs more intuitive and personalized. how AI will make PCs more personal This personalization will likely impact the way Intel chips are designed and utilized in the future.

Ultimately, the automotive and PC industries are intertwined, and both are heavily influenced by innovative chip design.

Safety and Reliability Considerations

Automotive chips must withstand harsh operating conditions and operate reliably under various environmental stresses. The safety-critical nature of these chips necessitates rigorous testing and validation to ensure their resilience against unexpected events. Redundancy and fault tolerance are key design elements, protecting against failures that could compromise the safety of passengers. Robust error handling and recovery mechanisms are implemented to minimize the impact of any potential glitches.

Design choices prioritize safety over speed in many instances.

Real-time Performance Demands

The dynamic nature of in-vehicle systems demands real-time responsiveness. Infotainment systems, driver-assistance systems, and powertrain control systems require rapid processing and precise timing. Intel’s chip designs leverage advanced architectures and optimized algorithms to meet these performance expectations. This includes careful consideration of power consumption, ensuring that real-time processing does not compromise the battery life of the vehicle.

Addressing Specific Car Systems

Intel’s chip designs address the specific needs of various car systems. Their solutions are adaptable, catering to the unique requirements of different components.

- Infotainment Systems: These systems require processing power for complex graphical user interfaces (GUIs), seamless multimedia playback, and fast response times for user interactions. Intel’s designs focus on efficient processing for these tasks, ensuring a smooth and engaging user experience.

- Driver-Assistance Systems: Advanced driver-assistance systems (ADAS) necessitate extremely fast processing and accurate sensor data interpretation. Intel’s chips are designed to handle the complex calculations required for object detection, lane keeping, and collision avoidance, ensuring rapid and precise responses to changing conditions.

- Powertrain Control: Powertrain control units (PCUs) need highly reliable and precise control over engine performance and fuel efficiency. Intel’s chip designs optimize fuel economy and power delivery, while ensuring the system operates safely and predictably.

Key Performance Metrics for Automotive Chips

Several critical performance metrics are paramount for automotive chips. These metrics reflect the chip’s ability to handle the demanding real-time processing requirements of various vehicle systems.

- Processing Speed: The speed at which the chip executes instructions directly impacts the responsiveness of in-vehicle systems. Higher processing speeds are crucial for handling complex calculations and enabling real-time processing.

- Power Efficiency: Automotive chips need to minimize power consumption to maximize battery life. Intel’s designs prioritize power efficiency to extend the vehicle’s operational range and reduce energy costs.

- Reliability: The robustness of the chip under varying environmental conditions and prolonged use is critical for automotive applications. Intel’s designs prioritize resilience to maintain the safety and reliability of the vehicle.

Examples of Intel Automotive Chips

Intel has designed specific chips for automotive applications, each tailored to meet the needs of different car systems.

- Example 1 (Hypothetical): A chip designed for infotainment systems might include specialized hardware for graphics processing, ensuring smooth transitions between screens and applications. It would also leverage efficient algorithms for multimedia processing. This specific chip would be optimized for power efficiency, enabling extended battery life for the vehicle.

- Example 2 (Hypothetical): A chip for driver-assistance systems could integrate advanced sensor interfaces and optimized algorithms for object detection. The chip would likely feature specialized hardware accelerators for real-time image processing, ensuring swift and accurate responses to changing road conditions. The focus on low power consumption would extend the battery life of the ADAS system.

Car Companies and Intel’s Chips

Intel’s foray into the automotive sector has been a significant development, potentially reshaping the landscape of in-car computing. This section delves into the intricate relationships between Intel and major automotive companies, analyzing the factors driving chip procurement decisions and evaluating the impact of Intel’s strategy on these partnerships. Understanding these dynamics is crucial for assessing Intel’s position within the evolving automotive chip market.Intel’s strategy in the automotive industry is not just about supplying chips; it’s about establishing long-term partnerships built on mutual trust and shared goals.

This involves a delicate balance of factors, from ensuring compatibility and reliability to meeting specific performance requirements and budgetary constraints. The success of Intel’s automotive chip strategy hinges on its ability to cater to the diverse needs of various car manufacturers and adapt to the evolving demands of the automotive industry.

Relationships with Major Automotive Companies

Intel’s relationships with major automotive companies are characterized by a blend of established partnerships and new collaborations. Some existing partnerships are likely strengthened through a shared history, while others are more recent engagements, driven by the strategic importance of automotive computing. These relationships encompass various aspects of chip design, development, and supply chain integration, emphasizing the intricate interconnectedness of the automotive and technology sectors.

Successful collaborations require a deep understanding of the specific requirements of each manufacturer.

Factors Influencing Chip Procurement Decisions

Car companies meticulously evaluate numerous factors when selecting chips for their vehicles. Cost is a primary concern, influencing the financial viability of the project. Performance requirements vary significantly across different vehicle models, from basic driver-assistance systems to advanced autonomous driving features. Reliability is paramount, as issues with vehicle electronics can have serious consequences, impacting safety and customer satisfaction. Furthermore, the ability of the chip supplier to adapt to future developments and integrate new technologies plays a key role in long-term strategic considerations.

Table: Car Companies Using Intel’s Chips

The following table provides a simplified overview of car companies potentially utilizing Intel chips for various applications. Data is limited due to the dynamic nature of industry partnerships and confidentiality agreements. The table demonstrates the breadth of potential applications and highlights the evolving role of Intel in the automotive sector.

| Car Company | Application |

|---|---|

| General Motors | Driver-assistance systems, infotainment |

| Ford | Advanced driver-assistance systems, connectivity |

| Volkswagen | Infotainment, safety features |

| Toyota | Infotainment, driver-assistance systems |

| Honda | Driver-assistance systems, infotainment |

Impact on Relationships with Major Car Manufacturers

Intel’s automotive chip strategy significantly impacts the relationships with major car manufacturers. The ability to provide high-performance, reliable chips directly affects the manufacturer’s ability to deliver advanced features and maintain a competitive edge in the market. Successful partnerships often lead to increased sales and market share. Conversely, challenges in delivering on commitments can strain relationships and potentially lead to loss of business.

Stronger relationships foster innovation and collaboration in future automotive technologies.

Future of Intel in Automotive

Intel’s foray into the automotive sector is a significant strategic move, and its future success hinges on adapting to the rapidly evolving landscape of automotive chip technology. The demand for sophisticated computing capabilities within vehicles is steadily increasing, and Intel must proactively position itself to meet these evolving needs. This includes anticipating future trends, leveraging emerging technologies, and forging strategic partnerships.

Potential Future Trends in Automotive Chip Technology

The automotive industry is undergoing a transformation, moving from basic electronic controls to complex, integrated systems. Future automotive chips will likely see increased integration of functionalities, encompassing not only powertrain and safety systems but also advanced driver-assistance systems (ADAS) and eventually, autonomous driving capabilities. This trend necessitates chips with higher processing power, greater bandwidth, and improved energy efficiency.

Predictions suggest an increasing demand for specialized hardware accelerators, particularly for tasks like image processing and AI inference.

Impact of AI and Machine Learning on Intel’s Automotive Chip Designs

AI and machine learning are poised to revolutionize the automotive experience. Intel’s automotive chips will need to incorporate AI and machine learning capabilities to enable features like advanced driver-assistance systems (ADAS) and autonomous driving. This will require specialized hardware accelerators for tasks such as object detection, scene understanding, and decision-making. Intel will need to develop algorithms and tools that optimize AI models for real-time execution on their automotive chips.

Successful implementation will depend on Intel’s ability to leverage its existing expertise in hardware and software.

Positioning Intel for Competitive Advantage in the Evolving Automotive Chip Market

Intel’s strategy for maintaining a competitive edge in the automotive chip market should focus on several key areas. First, Intel needs to invest heavily in research and development to stay ahead of emerging trends. Second, forging strategic partnerships with automotive manufacturers will be crucial. Third, leveraging its existing infrastructure and expertise in semiconductor design and manufacturing is vital.

Intel’s strong presence in the data center market could offer a unique advantage, enabling it to transfer expertise in high-performance computing to the automotive sector.

Potential Future Collaborations Between Intel and Car Manufacturers

Successful collaboration is key to Intel’s success in the automotive sector. Intel must explore opportunities to work with automotive manufacturers to tailor chip designs to specific vehicle needs. The table below illustrates potential future partnerships, highlighting areas of mutual benefit:

| Car Manufacturer | Potential Collaboration Area | Mutual Benefit |

|---|---|---|

| General Motors | Developing specialized chips for autonomous driving features | GM benefits from advanced driving capabilities, Intel gains access to a large automotive market. |

| Toyota | Improving efficiency of hybrid and electric vehicle powertrains | Toyota enhances its powertrain efficiency, Intel gains experience in energy-efficient computing. |

| Volkswagen | Creating a robust infotainment system with advanced connectivity | Volkswagen improves user experience, Intel gains insights into the future of automotive connectivity. |

| Ford | Developing advanced safety features utilizing machine learning | Ford enhances vehicle safety, Intel strengthens its AI expertise in the automotive market. |

Pat Gelsinger’s Vision for Intel in the Automotive Sector: Intel Chips Automotive Industry Car Companies Fabs Production Pat Gelsinger

Pat Gelsinger, Intel’s CEO, has Artikeld a significant shift in Intel’s strategy, aiming to capitalize on the burgeoning automotive chip market. He recognizes the growing demand for sophisticated and powerful chips within vehicles and is actively positioning Intel to become a major player in this sector. This vision involves more than just supplying chips; it’s about leveraging Intel’s core strengths in design and manufacturing to create innovative solutions for the future of mobility.Gelsinger’s leadership has undeniably influenced Intel’s automotive strategy.

His emphasis on long-term investments, particularly in advanced semiconductor technologies, signals a commitment to developing cutting-edge solutions for the automotive industry. This proactive approach aligns with the automotive industry’s evolving needs for sophisticated computing power and advanced safety features within vehicles.

Intel’s Automotive Chip Design Focus

Intel is focusing on developing chips tailored specifically for the unique demands of automotive applications. This includes features like high reliability, robust performance under extreme conditions, and secure operation. The company is emphasizing the integration of various functionalities within a single chip, which reduces the complexity and cost of vehicle systems. This integrated approach enables better control and management of vehicle systems, including the infotainment system, advanced driver-assistance systems (ADAS), and power management.

Strategic Partnerships and Collaborations, Intel chips automotive industry car companies fabs production pat gelsinger

Intel is actively engaging in partnerships with major automotive companies to understand their specific needs and develop tailored solutions. This collaborative approach is crucial for effectively addressing the unique requirements of different vehicle models and designs. These collaborations allow Intel to gain insights into the evolving needs of the automotive industry and adapt its chip designs accordingly. Examples include joint ventures in specific areas of automotive technology.

Manufacturing and Production Capabilities

Intel’s robust manufacturing capabilities, including its fabs, are critical for producing high-volume automotive chips with the required quality and reliability. The company is investing heavily in its fabrication facilities to meet the rising demand for automotive semiconductors. This includes upgrades to existing facilities and the potential construction of new ones, ensuring the ability to handle the increased production volume expected in the future.

Intel’s extensive experience in manufacturing high-performance chips will translate to delivering reliable automotive solutions.

Impact of Gelsinger’s Vision on the Future of Intel

Gelsinger’s vision for Intel’s automotive strategy positions the company to play a key role in the evolution of mobility. By focusing on innovative chip designs, strategic partnerships, and robust manufacturing capabilities, Intel aims to establish a strong presence in this crucial market segment. This shift in strategy reflects a long-term commitment to the automotive industry and suggests a belief in the significant potential for growth and innovation in this area.

Production Challenges and Strategies

Intel’s foray into the automotive chip market presents a unique set of production challenges, requiring innovative strategies to compete effectively. These challenges are not just about scaling up production, but also about integrating complex designs into a demanding and highly regulated environment. The need for high reliability, stringent quality standards, and rapid response to evolving automotive technologies are crucial factors that need to be addressed.The automotive industry demands extreme levels of reliability and safety, making chip production for cars more demanding than for other sectors.

This necessitates a sophisticated approach to manufacturing, including stringent quality control measures, robust testing procedures, and efficient supply chain management. Furthermore, the sheer complexity of automotive systems, coupled with the need for customized solutions for various car models, adds to the manufacturing intricacies.

Major Production Challenges

Intel faces several significant production challenges in the automotive sector. These include:

- High-Volume, Low-Margin Manufacturing: The automotive market demands high production volumes to meet the needs of various car manufacturers. However, the margins in the automotive chip market are often lower compared to other segments. Intel must balance high-volume production with cost-effectiveness to maintain profitability.

- Strict Quality and Reliability Standards: Automotive chips are critical components, playing a crucial role in safety-critical systems. Therefore, the automotive industry mandates stringent quality and reliability standards that go beyond those of other markets. Meeting these requirements necessitates specialized manufacturing processes and rigorous testing procedures.

- Complex Integration with Existing Automotive Systems: Automotive chips must integrate seamlessly with existing vehicle systems and networks. This often involves working with multiple suppliers and integrating with various interfaces, protocols, and standards, which adds complexity to the production process.

- Shortage of Skilled Labor: Advanced chip manufacturing requires a specialized workforce with specific expertise in semiconductor fabrication. The shortage of skilled labor can limit production capacity and impact timelines.

Strategies for Overcoming Challenges

Intel can implement several strategies to overcome these production hurdles:

- Investment in Advanced Manufacturing Facilities: Intel should invest in advanced fabrication plants specifically designed for automotive chips. These facilities should be equipped with cutting-edge equipment and processes to ensure high yield, quality, and reliability. The company can leverage its existing expertise in semiconductor manufacturing and apply it to the specific needs of automotive chips.

- Partnerships and Collaborations: Forming strategic partnerships with automotive suppliers, Tier-1 suppliers, and other companies specializing in automotive electronics can help Intel leverage expertise and resources to improve production efficiency. Joint ventures or collaborative agreements can also help Intel gain a better understanding of automotive system integration requirements.

- Automation and Process Optimization: Implementing advanced automation technologies in the manufacturing process can increase production efficiency, reduce human error, and improve quality control. Optimizing existing processes, leveraging data analytics, and implementing lean manufacturing principles can further enhance efficiency.

- Talent Acquisition and Development: Intel should proactively address the shortage of skilled labor by implementing targeted recruitment strategies and investing in training programs. Attracting and retaining talent with expertise in automotive semiconductor technologies is crucial for long-term success.

Risk and Reward Analysis

| Production Strategy | Potential Risks | Potential Rewards |

|---|---|---|

| Investment in Advanced Manufacturing Facilities | High upfront capital investment, potential delays in construction and equipment deployment | Enhanced production capacity, higher yields, improved quality, and a competitive advantage |

| Partnerships and Collaborations | Potential conflicts of interest, dependency on partners, and difficulty in coordinating efforts | Access to new technologies, expertise, and markets, reduced development costs, and faster time to market |

| Automation and Process Optimization | Implementation challenges, potential job displacement, and high initial investment | Increased production efficiency, reduced costs, improved quality, and enhanced competitiveness |

| Talent Acquisition and Development | Difficulty in attracting and retaining talent, high training costs, and potential delays in skill development | Improved workforce capabilities, enhanced innovation, and increased productivity |

Current Production Capacity

Intel’s current production capacity for automotive chips is a key factor in its ability to meet market demand. The company needs to assess its existing manufacturing capabilities, including the capacity of its existing fabs and potential expansion plans. Furthermore, a detailed analysis of the current production lines and their suitability for automotive chip manufacturing is needed. Intel needs to identify any bottlenecks in its existing production processes and plan for future capacity expansions.

Ultimate Conclusion

In conclusion, Intel’s automotive chip strategy under Pat Gelsinger presents a compelling case study in adapting to a dynamic market. The challenges of production, the intricacies of design, and the evolving relationship with car manufacturers are all pivotal elements in this evolving landscape. Ultimately, Intel’s success in this sector hinges on its ability to meet the specific needs of the automotive industry while leveraging its strengths in chip design and production.

The future is bright, but the road ahead will be paved with strategic choices.