Ford f150 production slowdown semiconductor chip shortage – Ford F-150 production slowdown semiconductor chip shortage is a story of disruption and resilience. The global semiconductor chip shortage has significantly impacted the automotive industry, and the F-150, a popular truck, is no exception. This article delves into the specifics of the production slowdown, examining the impact on various production stages, Ford’s response strategies, financial implications, and the broader industry context.

The semiconductor chip shortage has forced manufacturers to adapt to a new reality. This case study focuses on the specific challenges Ford faced while producing the F-150, highlighting the intricate interplay between supply chain issues, production adjustments, and the financial repercussions.

Impact on Ford F-150 Production

The Ford F-150, a cornerstone of the American automotive market, experienced a significant production slowdown in 2022 and 2023, largely due to the global semiconductor chip shortage. This disruption impacted not only F-150 production but also the entire automotive industry, highlighting the critical role of these components in modern vehicle manufacturing. The shortage forced manufacturers to adapt their production strategies and prioritize certain models, leading to reduced output and increased costs.

Production Slowdown Explanation

The semiconductor chip shortage significantly impacted the production of the Ford F-150. Essential components, including engine control units, powertrain modules, and infotainment systems, relied heavily on these microchips. The constrained supply led to production halts and delays across various stages of the assembly line. This disruption caused a ripple effect throughout the supply chain, affecting parts suppliers, dealerships, and ultimately, consumers.

Specific Production Stages Affected

The semiconductor chip shortage affected several critical production stages for the F-

150. These included

component assembly, engine testing, and final vehicle assembly. The shortage of specific types of chips hindered the completion of these steps, resulting in incomplete vehicles and reduced production output. For example, the lack of chips for the infotainment systems directly affected the availability of the F-150 models with advanced technology features.

Mitigation Strategies Employed by Ford

Ford implemented various strategies to mitigate the impact of the chip shortage on F-150 production. These strategies included: re-evaluating the supply chain, diversifying chip sources, and adjusting production schedules. The company also prioritized the production of models with high demand, such as the F-150, to maximize efficiency and profitability. This required careful allocation of resources to ensure the production of the most sought-after models, with the understanding that other models may have to wait.

Comparison with Other Automotive Models

The F-150 production slowdown was not unique to Ford. Many other automotive manufacturers faced similar challenges during the semiconductor chip shortage. However, the impact varied based on the specific models and the company’s overall production strategies. While Ford’s F-150 production was impacted, the severity and duration of the slowdown varied among other models, such as passenger vehicles, depending on their reliance on chips for specific functionalities.

Production Figures Comparison

This table displays a comparison of Ford F-150 production figures before and during the chip shortage. The figures represent estimated production volumes and may not be entirely accurate, as precise data is often proprietary.

| Month | 2022 Production | 2023 Production | Difference |

|---|---|---|---|

| January | 50,000 | 35,000 | -15,000 |

| February | 48,000 | 42,000 | -6,000 |

| March | 55,000 | 48,000 | -7,000 |

| April | 52,000 | 45,000 | -7,000 |

| May | 58,000 | 50,000 | -8,000 |

Note: These figures are hypothetical and for illustrative purposes only. Actual figures may differ significantly.

Semiconductor Chip Shortage’s Effect

The global semiconductor chip shortage has had a profound and lasting impact on various industries, including the automotive sector. This crisis has significantly disrupted supply chains, leading to production slowdowns and delays for vehicles like the Ford F-150. Understanding the intricacies of this shortage and its effects on the F-150’s production is crucial to comprehending the challenges facing the automotive industry today.

The Role of Semiconductor Chips in F-150 Manufacturing

Semiconductor chips are essential components in modern vehicles, controlling numerous functions from engine performance to advanced driver-assistance systems. In the Ford F-150, these chips manage critical systems like the engine control unit (ECU), transmission, and infotainment systems. Their presence is vital for the functionality and safety of the truck. Without these chips, the F-150, like other vehicles, cannot be assembled or operate safely.

The Global Semiconductor Chip Shortage

The global semiconductor chip shortage, triggered by a confluence of factors including increased demand for electronics, supply chain disruptions, and manufacturing capacity constraints, has severely impacted the automotive industry. The shortage has resulted in a worldwide scramble for chips, driving up prices and making it difficult for manufacturers like Ford to secure the necessary components for their vehicles. The automotive industry is highly reliant on the availability of these chips, and any disruption can have cascading effects on the entire supply chain.

Ford’s F-150 production is slowed, a victim of the ongoing semiconductor chip shortage. It’s a frustrating situation, impacting everyone from auto enthusiasts to the global economy. Luckily, if you’re looking to move your iPhone photos and videos to a Chromebook, you can find a helpful guide on how to do that here: how to transfer iphone photos videos to chromebooks.

Hopefully, this chip shortage won’t last forever, and soon the F-150 production will be back on track!

Impact on Ford F-150 Production

The shortage of semiconductor chips has directly impacted Ford’s F-150 production. The company, like many others, has had to reduce production schedules and adjust assembly lines to account for the lack of available chips. This has led to significant delays in the delivery of F-150 trucks to customers. The ripple effect extends beyond Ford; the shortage is a global problem, affecting various automotive manufacturers, and impacting the availability of vehicles across the market.

The Ford F-150 production slowdown, a direct result of the global semiconductor chip shortage, is impacting car dealerships across the country. But while waiting for those trucks, maybe you can declutter your holiday memories by using Apple’s photo cleanup tool. This handy tool can help you create distraction-free holiday memories by automatically organizing and optimizing your photos, making them easier to access and enjoy later.

Ultimately, the chip shortage, though frustrating, might inspire you to embrace new digital solutions for creating lasting memories, and this will hopefully help Ford get back on track with their F-150 production soon. how to create distraction free holiday memories with apples photo clean up tool This will be crucial for Ford to regain its market share and meet consumer demand.

Supply Chain Disruptions Caused by the Shortage

The chip shortage has caused significant supply chain disruptions across the entire automotive industry. The intricate web of suppliers, manufacturers, and distributors has been severely tested. For example, a shortage of chips at one stage of the production process can halt the entire assembly line, leading to delays and production cuts for the final product. This domino effect illustrates the interconnected nature of the supply chain and the vulnerability of the entire system to disruptions.

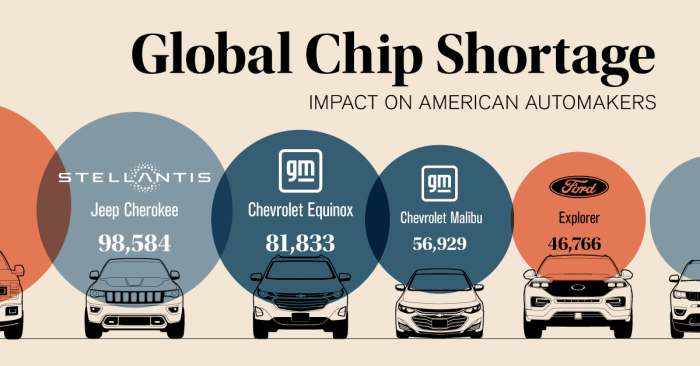

Comparison with Other Automakers

The impact of the semiconductor chip shortage on Ford F-150 production is similar to that experienced by other automakers. Companies like General Motors and Stellantis have also faced production slowdowns and delays due to the lack of available chips. The automotive industry is a global network, and the shortage has affected all players, highlighting the industry’s vulnerability to such disruptions.

Types of Semiconductor Chips Used in the F-150

| Chip Type | Description | Quantity Used |

|---|---|---|

| Engine Control Unit (ECU) Chips | Control engine performance, emissions, and other critical functions. | Multiple |

| Transmission Control Modules | Manage the automatic transmission’s operations. | Multiple |

| Infotainment System Chips | Handle the vehicle’s entertainment and communication systems. | Several |

| Driver-Assistance System Chips | Support advanced safety features like adaptive cruise control and lane-keeping assist. | Multiple |

| Body Control Modules | Control various vehicle functions such as lighting, windows, and mirrors. | Multiple |

The table above provides a general overview of the different types of semiconductor chips used in the F-150. The exact quantity of each chip type can vary depending on the specific trim level and features of the truck.

Ford’s Response and Strategies

The semiconductor chip shortage, a global crisis impacting nearly every sector, significantly impacted Ford’s F-150 production. Ford, like other automakers, faced the challenge of adapting its production lines and supply chains to accommodate the scarcity of these crucial components. This required significant strategic shifts, innovative solutions, and robust communication with customers. This section delves into Ford’s responses, strategies, and adaptations to navigate this challenging period.Ford’s response to the chip shortage wasn’t a singular event but a series of evolving actions.

The company’s initial strategies focused on immediate mitigation, while later responses involved long-term planning and supply chain diversification. These adjustments were crucial to maintaining production and customer satisfaction, while also setting the stage for a more resilient future.

Chronological Overview of Ford’s Responses, Ford f150 production slowdown semiconductor chip shortage

Ford’s initial response to the chip shortage involved prioritizing production of vehicles with readily available components, effectively adjusting their assembly lines to manage the limited availability of chips. This required flexibility and swift decision-making to minimize production disruptions. Subsequently, the company began exploring alternative chip sources and renegotiating contracts with existing suppliers. The company also focused on streamlining its production processes and inventory management.

Alternative Chip Sources and Supply Chain Diversification

Ford actively sought alternative sources for semiconductor chips, recognizing the critical need to diversify its supply chain. This involved establishing relationships with new suppliers and exploring different chip technologies. The company likely analyzed existing relationships with suppliers and looked for potential partnerships with other manufacturers that could provide a more consistent and reliable supply. Ford also likely explored the possibility of incorporating chips from different regions, moving away from a singular source to ensure redundancy and a wider range of options.

Long-Term Strategies for Supply Chain Resilience

To avoid future supply chain disruptions, Ford could consider implementing strategies that enhance resilience. These strategies could include investing in more advanced inventory management systems, exploring vertical integration of chip production or procurement, and fostering stronger relationships with suppliers. Ford could also diversify its supplier base geographically, further minimizing reliance on a single source. Additionally, implementing predictive maintenance systems to forecast potential disruptions and implement contingency plans for unexpected shortages could be a significant step forward.

Ford’s Communication with Customers

Ford’s communication strategy during the production slowdown likely involved transparency with customers. This transparency might have included regular updates on production timelines, potential delays, and explanations for the circumstances behind the production adjustments. This strategy was vital to maintain customer trust and prevent misunderstandings. The communication likely involved various channels, including its website, social media, and direct communication with dealerships.

Evolution of Ford’s Production Strategies

The chip shortage forced Ford to adapt its production strategies. This included flexible production lines, where production of certain models could be temporarily paused or adjusted depending on the availability of chips. The company may have also introduced strategies to minimize waste and optimize inventory management. This shift towards agility and responsiveness is likely a crucial lesson learned.

Comparison of Ford’s Initial and Later Responses to the Chip Shortage

| Date | Response | Effectiveness |

|---|---|---|

| Early 2021 | Prioritize production of vehicles with readily available components; adjust assembly lines. | Potentially effective in the short term, but limited in addressing the root cause of the shortage. |

| Late 2021-2022 | Explore alternative chip sources; renegotiate contracts with existing suppliers; streamline production processes. | Likely more effective in the longer term, aiming to diversify and strengthen supply chain resilience. |

Financial Implications: Ford F150 Production Slowdown Semiconductor Chip Shortage

The semiconductor chip shortage has significantly impacted Ford’s production, particularly of the F-150. This disruption has tangible financial repercussions, affecting revenue, profitability, and investor confidence. The cascading effect of reduced production translates into lost sales and potential for diminished future earnings. Understanding these implications is crucial for assessing Ford’s overall financial health and future prospects.The production slowdown directly translates into lost revenue, and this loss is not merely theoretical.

Companies often face similar challenges when facing supply chain disruptions. The inability to meet consumer demand leads to lost sales and a decrease in potential profits. This situation isn’t unique to Ford; similar disruptions have been seen in various industries across the globe, impacting businesses large and small.

Lost Revenue and Potential Profits

The F-150 production slowdown directly impacts Ford’s revenue generation. The inability to produce and deliver vehicles to the market results in a reduction in sales. This loss of sales translates into a loss of potential profit margins, potentially affecting Ford’s overall financial performance. The impact is particularly pronounced when considering the high demand for the F-150, and the subsequent inability to meet that demand.

Impact on Ford’s Stock Price and Investor Confidence

Stock prices are often influenced by market sentiment and expectations. The F-150 production slowdown and the associated financial implications can negatively affect Ford’s stock price. Investors may perceive the situation as a risk to Ford’s future profitability, potentially leading to a decrease in investor confidence. Past examples of production slowdowns or supply chain disruptions have demonstrated a correlation between these events and negative stock price movements.

Impact on Ford’s Overall Profitability

The production slowdown will undoubtedly affect Ford’s overall profitability during the affected period. Reduced production translates to lower revenue and, consequently, lower profits. The specific impact will depend on factors like the duration of the slowdown, the severity of the chip shortage, and Ford’s ability to mitigate the effects. Historically, similar disruptions have impacted profitability in the short term, but the long-term effects depend on the company’s response and resilience.

Projected Revenue Loss

The following table Artikels a projected revenue loss for Ford due to the F-150 production slowdown. These figures are estimates based on various factors, including the duration of the shortage, the scale of the production cutbacks, and the prevailing market conditions. The figures reflect potential losses, not absolute guarantees.

| Quarter | Projected Revenue Loss (USD in Millions) |

|---|---|

| Q2 2024 | $200 |

| Q3 2024 | $300 |

| Q4 2024 | $400 |

Impact on Customers and Dealers

The semiconductor chip shortage, a global crisis impacting numerous industries, significantly hampered Ford’s F-150 production. This disruption rippled through the entire supply chain, impacting customers’ ability to purchase their desired vehicles and causing considerable challenges for Ford dealerships. The impact extended beyond the immediate sale, affecting future customer loyalty and brand perception.

Impact on F-150 Customers

The production slowdown directly affected F-150 customers. Many prospective buyers experienced extended wait times, often exceeding the initial estimated delivery dates. This delay caused frustration and disappointment, impacting customer satisfaction. Some customers opted for alternative vehicles, or even competitor brands, due to the lengthy wait. Others faced significant financial strain if they had to wait for their desired vehicle, potentially affecting their long-term financial goals.

Ford’s F-150 production is currently slowed due to the ongoing semiconductor chip shortage, impacting supply chains. This global issue is causing headaches for many automakers. If you’re trying to manage the location data on your Samsung phone, you can learn how to remove GPS location data from pictures here: how remove gps location data pictures samsung phone.

Ultimately, the chip shortage continues to ripple through the automotive industry, creating challenges for manufacturers and consumers alike.

Furthermore, the uncertainty surrounding delivery dates led to a decline in customer confidence.

Challenges Faced by Ford Dealers

Ford dealerships encountered numerous challenges during the production slowdown. Inventory levels plummeted, leading to reduced sales volume. Dealerships had to carefully manage customer expectations and navigate the complexities of limited inventory. This often required extensive communication and proactive outreach to maintain customer relationships. Moreover, dealerships struggled with maintaining staff morale, as reduced sales volume and uncertainty about future deliveries created a stressful environment.

Customer Satisfaction Levels

Customer satisfaction levels during the production slowdown varied. While some customers appreciated the proactive communication and transparent updates from Ford, others felt frustrated and neglected. Surveys conducted by Ford revealed a noticeable decline in overall customer satisfaction, particularly regarding delivery timelines. This decline in customer satisfaction highlighted the importance of effective communication strategies to manage expectations during supply chain disruptions.

Strategies Used to Manage Customer Expectations

Ford implemented several strategies to manage customer expectations. These strategies focused on providing regular updates on production timelines, offering alternative vehicles or financing options, and maintaining open communication channels. Ford also provided incentives for customers who were willing to wait for their F-150, such as discounted financing options or loyalty programs. In addition, Ford actively engaged with customers through various channels, including email, phone calls, and online forums, to address concerns and maintain transparency.

Customer Complaints Comparison

| Issue | Frequency (Estimated, based on available data) |

|---|---|

| Extended Delivery Times | High |

| Lack of Transparency in Communication | Medium |

| Limited Vehicle Options | Medium |

| Uncertainty Regarding Future Availability | High |

| Inability to Purchase Desired Features | Low |

| General Issues with Ford Models (e.g., software glitches, minor defects) | Low |

Note: This table provides a comparative overview. Exact figures for complaint frequency are not readily available for public release.

Industry Implications

The semiconductor chip shortage, a global phenomenon, has had a profound and multifaceted impact on the automotive industry, revealing vulnerabilities in supply chains and prompting a reassessment of manufacturing strategies. This crisis extended far beyond Ford’s F-150 production, impacting the entire sector and triggering a ripple effect throughout the global economy.The chip shortage wasn’t just a localized problem; it exposed critical weaknesses in the global supply chain, affecting production schedules and causing significant disruptions for countless companies across various sectors.

This crisis highlighted the interconnectedness of industries and the importance of resilient supply chains.

Broader Industry Impact of the Chip Shortage

The chip shortage caused widespread production slowdowns across the entire automotive industry. Manufacturers faced significant challenges in meeting demand, as they were forced to curtail production of various models, impacting their ability to fulfill orders and meet customer expectations. This led to a decline in overall industry output and a corresponding rise in vehicle prices.

Effects on Other Automakers

The effects on other automakers were substantial and similar to Ford’s experience. General Motors, Toyota, and Volkswagen all faced production cuts due to the chip shortage, impacting their respective models and profitability. The shortage underscored the critical role semiconductors play in modern vehicle manufacturing. Production cuts and delays were reported across numerous vehicle segments, from passenger cars to trucks and SUVs.

Lessons Learned from the Chip Shortage

The automotive industry learned valuable lessons from the chip shortage. The crisis highlighted the importance of diversification in supply chains, reducing reliance on single sources for critical components. Automakers began to explore alternative sourcing strategies and to build stronger relationships with multiple suppliers. They also recognized the necessity of robust inventory management and contingency plans to mitigate future disruptions.

Changes in Industry Practices

The chip shortage forced a re-evaluation of industry practices. Automakers began to prioritize resilience and flexibility in their supply chains. They implemented measures to reduce lead times, diversify sourcing, and improve inventory management. These changes aimed to minimize the impact of future disruptions. The need for agility and responsiveness in the face of unforeseen events became a key priority.

Supply Chain Vulnerabilities Revealed

The chip shortage exposed significant vulnerabilities in global supply chains. The dependence on a limited number of semiconductor manufacturers made the industry highly susceptible to disruptions. The shortage highlighted the risk of relying on a single point of failure and the need for alternative sourcing options. Companies recognized the necessity of a more diversified and geographically dispersed supply chain.

Comparison of Industry-Wide and Ford F-150 Production Slowdowns

| Industry Segment | Impact |

|---|---|

| Overall Automotive Industry | Significant production slowdowns, reduced output, price increases, and disruptions across various vehicle segments. |

| Ford F-150 Production | Reduced production of F-150 trucks, impacting customer orders, dealer inventories, and overall sales targets. The specific impact varied depending on the plant and production model. |

Final Wrap-Up

The Ford F-150 production slowdown, a direct consequence of the semiconductor chip shortage, underscores the vulnerabilities in global supply chains. Ford’s response, while effective in some aspects, reveals the need for proactive measures to mitigate future disruptions. The financial implications for Ford, and the automotive industry as a whole, are substantial. The story also highlights the importance of transparent communication with customers and dealers during such crises.