CSAT solutions repair facility Texas apple macbook dell lenovo working conditions employees are a crucial aspect of the tech repair industry. This deep dive explores the working environments, employee satisfaction, and future trends within these facilities, focusing on the unique challenges and opportunities for those who repair Apple MacBooks, Dell laptops, and Lenovo devices in Texas.

From independent shops to corporate repair centers, this analysis compares working conditions, highlighting the differences in employee roles, responsibilities, and potential impacts on satisfaction and retention. We’ll examine factors influencing customer satisfaction scores, analyzing how efficient repair processes, timely repairs, and clear communication contribute to overall customer happiness.

Introduction to Repair Facilities

Repair facilities specializing in Apple MacBooks, Dell laptops, and Lenovo devices are crucial for maintaining the functionality of these valuable technological assets. These facilities play a vital role in the customer service experience, offering a range of services to keep electronic devices in optimal working order. From basic diagnostics to complex repairs and replacements, these facilities cater to a wide spectrum of needs.These facilities address the diverse needs of customers by providing specialized services tailored to different device models and repair requirements.

Their expertise in diagnosing and resolving technical issues contributes significantly to the longevity and reliability of electronic devices.

Types of Repair Facilities

Repair facilities for laptops and other electronic devices come in various forms, each with its own characteristics and service offerings. Independent shops often specialize in specific brands or types of repairs, while corporate repair centers typically handle the maintenance of a company’s fleet of devices. Retail stores frequently offer repair services as an add-on to their product sales, catering to both general consumers and business clients.

Services Offered

These facilities provide a spectrum of services to meet various needs. Diagnostics are conducted to identify the root cause of malfunctions. Repairs, encompassing everything from replacing faulty components to fixing software glitches, are crucial to restoring devices to their original functionality. Replacements are offered for parts or entire devices in certain circumstances, ensuring that customers receive the highest quality service and get their devices back in operation as soon as possible.

Comparison of Repair Facilities

| Facility Type | Location | Service Types | Pricing |

|---|---|---|---|

| Independent Repair Shop | Various locations, often in densely populated areas | Diagnostics, repairs, replacements of parts | Typically more competitive pricing for parts and labor, depending on the scope of work |

| Corporate Repair Center | Usually centralized locations, often near corporate headquarters | Diagnostics, repairs, replacements of parts, possibly device-specific training | Pricing is often dependent on the corporate agreement or contract |

| Retail Store Repair Center | Within retail locations, often with a wide product base | Diagnostics, basic repairs, replacements of parts, potentially more limited services | Pricing varies, potentially higher than independent shops, but may be convenient due to its proximity to the retail location |

Working Conditions for Employees

Repair facilities in Texas, encompassing independent shops and corporate centers, present diverse working conditions. These conditions vary significantly based on factors like facility size, ownership structure, and the specific brand of electronics they specialize in. Understanding these nuances is crucial for evaluating employee well-being and the overall success of these operations.The nature of repair work, often involving intricate technical procedures and potential exposure to hazardous materials, requires meticulous attention to detail and safety precautions.

Employee satisfaction and retention are directly linked to the working environment, impacting both productivity and the quality of service provided to customers.

Common Working Conditions

Repair facilities in Texas frequently operate with tight deadlines and fluctuating workloads. This dynamic environment often demands employees to be flexible and adapt to changing priorities. Common features include: a fast-paced environment with a focus on efficiency, limited workspace in some cases, and often long working hours during peak seasons or demanding projects. Specific tools and equipment, including specialized diagnostic tools, soldering stations, and testing equipment, are commonly used.

Comparison of Facility Types, Csat solutions repair facility texas apple macbook dell lenovo working conditions employees

Independent repair shops often exhibit a more personalized and flexible atmosphere. They may have less formalized structures and a greater emphasis on building customer relationships. Conversely, corporate centers tend to have standardized procedures, greater access to resources, and potentially more formalized training programs. This disparity impacts the level of autonomy and decision-making authority employees experience. Differences in benefits packages, employee compensation, and overall organizational culture also arise.

Employee Roles and Responsibilities

A typical repair facility employee undertakes a range of tasks, from basic troubleshooting to advanced diagnostic procedures and component replacement. They are expected to maintain a high level of technical proficiency and adhere to strict safety protocols. These professionals frequently handle customer inquiries, manage inventory, and contribute to maintaining a clean and organized workspace. Furthermore, they may participate in preventative maintenance tasks, equipment upkeep, and potentially even contribute to training new hires.

Typical Employee Roles

- Technician: This role involves diagnosing and repairing electronic devices. Technicians must have strong technical skills, problem-solving abilities, and the capacity to work efficiently under pressure. They typically work on a variety of devices, from laptops to smartphones and other electronics.

- Customer Service Representative: Handling customer inquiries, scheduling appointments, and managing customer expectations is paramount. This role demands excellent communication skills, patience, and the ability to maintain a positive and helpful demeanor, even under challenging circumstances. This role plays a critical part in maintaining customer satisfaction.

- Inventory Manager: Managing parts inventory, ordering supplies, and ensuring the availability of necessary components are critical functions. This role requires organizational skills, attention to detail, and an understanding of parts lists and repair procedures. Maintaining accurate records is essential.

Required Skills for Each Role

| Employee Role | Responsibilities | Required Skills |

|---|---|---|

| Technician | Diagnosing and repairing electronic devices, following safety procedures, maintaining equipment, troubleshooting issues | Technical proficiency, problem-solving skills, attention to detail, mechanical aptitude, troubleshooting skills, strong knowledge of electronic components, safety protocols |

| Customer Service Representative | Answering customer inquiries, scheduling appointments, managing customer expectations, maintaining records, providing helpful and timely support | Excellent communication skills, active listening, patience, problem-solving, conflict resolution, customer service experience |

| Inventory Manager | Managing parts inventory, ordering supplies, ensuring availability of necessary components, maintaining records, organizing parts | Organizational skills, attention to detail, knowledge of parts lists, inventory management software, record-keeping, ability to prioritize tasks |

Employee Satisfaction and Retention

Repair facility employees, often dealing with technical complexities and customer demands, face unique challenges impacting their job satisfaction. Understanding these factors is crucial for creating a positive work environment and reducing employee turnover, ultimately leading to improved service quality and efficiency. High employee satisfaction translates to better customer service, reduced errors, and increased productivity.

Factors Influencing Employee Satisfaction

Employee satisfaction in repair facilities hinges on several key factors. Compensation and benefits packages are significant, but so are opportunities for professional growth, recognition, and a supportive work environment. Adequate training, clear communication channels, and opportunities for collaboration also contribute to a positive experience. Access to necessary tools and resources, along with the recognition of their efforts, further enhance job satisfaction.

Factors Contributing to Employee Turnover

High employee turnover in repair facilities can be attributed to various factors. Insufficient compensation relative to the market, lack of career advancement opportunities, and poor working conditions can all contribute to employee dissatisfaction and subsequent departures. A lack of recognition for contributions, or a lack of clear communication from management, also plays a role. Furthermore, a negative company culture, characterized by a lack of support or a sense of isolation, can significantly impact employee retention.

Company Culture and Management Style

Company culture and management styles have a direct impact on employee satisfaction and retention. A positive and supportive culture, where employees feel valued and respected, is more likely to retain talent. Open communication, trust, and empowerment are key elements of such a culture. Management styles that encourage collaboration, provide constructive feedback, and foster a sense of ownership contribute significantly to higher employee satisfaction and reduced turnover.

Strategies for Improving Employee Retention

Several strategies can improve employee retention in repair facilities. Implementing competitive compensation and benefits packages is a foundational step. Providing opportunities for professional development, such as training programs or mentorship opportunities, shows employees that the company invests in their growth. Recognizing and rewarding employee achievements, through formal or informal means, fosters a sense of appreciation and boosts morale.

Finally, fostering a positive company culture through team-building activities, social events, and clear communication channels reinforces employee loyalty and reduces turnover.

Employee Satisfaction Metrics

A comprehensive understanding of employee satisfaction requires monitoring various metrics. These metrics can be categorized as:

| Metric | Description | Measurement Method |

|---|---|---|

| Employee Turnover Rate | Percentage of employees leaving the company within a specific period. | Divide the number of employees who left by the average number of employees during that period, then multiply by 100. |

| Employee Satisfaction Surveys | Formal assessments gauging employee opinions on various aspects of their job. | Using structured questionnaires with standardized scales to measure satisfaction levels on aspects like compensation, training, work environment, and management. |

| Absenteeism Rate | Percentage of workdays missed by employees due to illness or other reasons. | Divide the total number of missed workdays by the total number of workdays available to employees during a period. |

| Employee Engagement | Level of enthusiasm, dedication, and commitment employees exhibit toward their work and the company. | Use engagement surveys or questionnaires measuring aspects like job satisfaction, organizational commitment, and perceived value to the organization. |

Implementing these strategies, combined with careful monitoring of employee satisfaction metrics, can significantly improve employee retention and create a more productive and successful repair facility.

Impact of Repair Facility Operations on Customer Satisfaction

The repair facility’s performance directly impacts customer satisfaction. A smooth, efficient, and courteous repair process can transform a frustrating experience into a positive one, leading to repeat business and positive online reviews. Conversely, a poorly run facility can damage a company’s reputation and drive customers to competitors. Understanding the nuances of this relationship is crucial for maximizing customer loyalty and profitability.Repair facility operations have a profound effect on the customer experience.

From the initial contact to the final resolution, every interaction shapes the customer’s perception of the entire process. This includes the speed of the repair, the quality of communication, and the professionalism of the staff. Positive experiences breed loyalty and advocacy, while negative ones can quickly lead to customer churn and a tarnished brand image.

Employee Performance and Customer Satisfaction Scores

Employee performance directly correlates with customer satisfaction. Well-trained, knowledgeable, and courteous technicians who understand the repair process and can explain it clearly to customers will often lead to better customer satisfaction scores. Conversely, poorly trained or unmotivated staff can create frustration and negatively impact the entire repair experience. Strong communication skills are essential; technicians should actively listen to customer concerns and explain the repair process in an accessible manner.

Proactive communication, including updates on repair progress and estimated completion times, fosters trust and reduces customer anxiety.

I’ve been researching the working conditions at CSAT Solutions repair facilities in Texas, specifically for Apple MacBooks, Dell laptops, and Lenovo devices. It’s crucial to understand the employee safety and well-being in these repair shops, especially given the recent focus on digital safety features like Apple’s new Safety Check in iOS 16. This new feature, detailed in safety check in iOS 16 puts abuse survivors back in control , highlights how important it is to prioritize digital well-being.

Ultimately, the conditions at CSAT, and similar repair shops, need to reflect the same values of empowerment and safety, for all their employees.

Efficient Repair Processes and Customer Feedback

Efficient repair processes are critical for maintaining high customer satisfaction. Streamlined workflows, well-maintained equipment, and readily available parts contribute to shorter repair times. Faster turnaround times, coupled with transparent updates on the repair status, result in happier customers. Effective processes minimize delays and frustration, ultimately leading to positive customer feedback. Customer feedback is a valuable tool for identifying areas for improvement within the repair facility operations.

I’ve been digging into the working conditions at CSAT Solutions’ repair facility in Texas, focusing on Apple MacBooks, Dell laptops, and Lenovo devices. It’s fascinating how these tech giants rely on repair shops like this, and the employees’ well-being is paramount. Interestingly, the recent buzz around Robert Downey Jr, Mark Zuckerberg, and Facebook’s AI voice technology ( robert downey jr mark zuckerberg facebook ai voice ) reminds me of the need for transparency and fair treatment in the tech supply chain.

Ultimately, these factors impact the quality of the products we all use, making employee satisfaction at CSAT Solutions crucial.

Analyzing this feedback allows for process optimization and staff training, ensuring continuous improvement in service quality.

Timely Repairs and Effective Communication

Timely repairs are paramount to customer satisfaction. Customers want their devices repaired as quickly as possible while maintaining quality service. Effective communication plays a critical role in this aspect. Regular updates on the repair progress, including estimated completion times, provide customers with a clear picture of the repair process. Maintaining open communication channels, through phone calls, emails, or online portals, keeps customers informed and involved.

Transparency and prompt communication during the repair process are essential for a positive experience. Providing clear, concise, and timely updates builds trust and confidence in the repair facility.

Metrics for Repair Efficiency and Customer Satisfaction

The following table displays key metrics for evaluating repair facility efficiency and customer satisfaction. Regular monitoring of these metrics allows for identification of trends and areas needing improvement.

| Metric | Description | Target Value |

|---|---|---|

| Repair Time (Average) | Average time taken to complete a repair | Within 24-48 hours for most common repairs |

| Customer Satisfaction Score (CSAT) | Percentage of customers rating their repair experience positively | 90% or higher |

| Customer Feedback Response Time | Time taken to respond to customer feedback | Within 24 hours |

| Technician Training Completion Rate | Percentage of technicians completing required training | 100% |

| Parts Availability | Percentage of necessary parts readily available | 95% or higher |

Future Trends and Innovations

The repair landscape for consumer electronics is constantly evolving. Texas, with its robust tech sector and significant consumer demand, is poised to see exciting changes in how repair facilities operate. Emerging technologies and shifting customer expectations are reshaping the way these facilities approach repairs for Apple MacBooks, Dell laptops, and Lenovo devices. This evolution demands a forward-thinking approach to ensure continued success.

I’ve been looking into the working conditions at CSAT Solutions repair facility in Texas, focusing on Apple MacBook, Dell, and Lenovo repairs. It’s interesting to see how the tech repair industry is impacting employee well-being, and how companies like CSAT are handling that. This is particularly relevant when considering the recent news about Game Informer returning to Gamestop game informer returning gamestop.

Ultimately, I’m still trying to piece together how the changing landscape of gaming and tech repair services is affecting workers across the board.

Predicting Future Trends in Repair Facility Operations

Repair facilities in Texas are likely to experience a shift towards greater automation and data-driven decision-making. This trend is already evident in other industries, and its application in repair services is rapidly gaining traction. Predictive maintenance, using sensor data and machine learning, can help anticipate potential equipment failures, reducing downtime and optimizing resource allocation.

Emerging Technologies and Applications

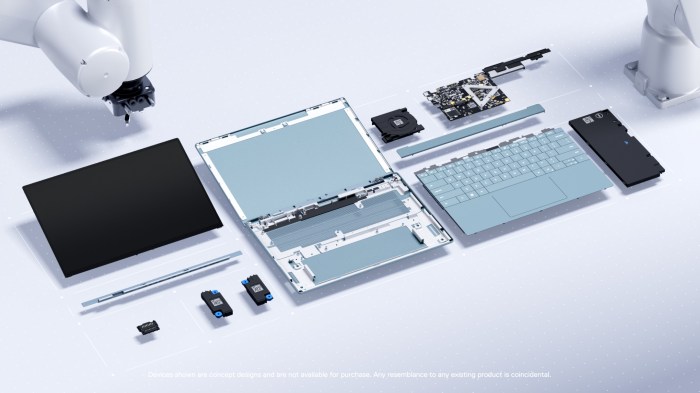

Several technologies are poised to revolutionize repair facility operations. Artificial intelligence (AI) and machine learning (ML) are crucial for automating diagnostics, enabling faster and more accurate problem identification. For instance, AI-powered image recognition can analyze damage patterns in components, providing detailed assessments and streamlining the repair process. 3D printing and rapid prototyping technologies can also play a key role in providing custom-made parts or quickly producing replacements for damaged components, drastically reducing repair time.

Furthermore, advanced diagnostic tools that integrate with repair software can allow technicians to access real-time information, reducing the need for extensive manual research.

Impact on Employee Roles and Working Conditions

The integration of these technologies will inevitably reshape employee roles. Technicians will need to adapt their skillsets, acquiring expertise in using AI-powered tools and software. This transition will require retraining and upskilling initiatives to ensure a smooth transition. While automation will take over some routine tasks, human expertise will remain crucial for complex repairs and troubleshooting situations that require judgment and problem-solving.

The overall working conditions could improve with reduced manual labor, allowing technicians to focus on more strategic aspects of the repair process, increasing job satisfaction.

Improving Repair Efficiency with Technological Advancements

Technological advancements can significantly improve repair efficiency in several ways. AI-powered diagnostic tools can identify the root cause of malfunctions much faster than traditional methods, reducing the time spent on troubleshooting. 3D printing can accelerate the production of replacement parts, enabling quicker repairs. Furthermore, the use of robotic arms for repetitive tasks can significantly enhance speed and accuracy in the repair process.

By incorporating these technologies, repair facilities can significantly reduce repair times and increase overall productivity.

Summary of Predicted Future Trends and Impacts

| Future Trend | Impact on the Sector |

|---|---|

| Increased Automation | Reduced repair time, improved accuracy, potential for job displacement requiring retraining. |

| AI-powered Diagnostics | Faster diagnosis, more accurate assessments, improved repair efficiency. |

| 3D Printing for Parts | Reduced repair time, lower inventory costs, ability to create custom parts. |

| Advanced Diagnostic Tools | Improved technician efficiency, real-time information access, reduced research time. |

| Data-driven Decision Making | Optimized resource allocation, improved inventory management, predictive maintenance. |

Comparative Analysis of Brands

Choosing the right repair facility for your tech devices often comes down to more than just price. Understanding the nuances of different brands’ repair policies, customer service, and employee training is crucial for a smooth and satisfying experience. This analysis delves into the distinct approaches of Apple, Dell, and Lenovo, highlighting their strengths and weaknesses in the repair landscape.

Repair Policies and Procedures

Different brands employ varying repair policies, impacting everything from turnaround times to cost. These policies reflect the complexities of device design, the availability of parts, and the brand’s commitment to customer satisfaction.

| Brand | Repair Policy Highlights | Turnaround Time (estimated) | Out-of-Warranty Costs |

|---|---|---|---|

| Apple | Apple often favors in-house repair centers or authorized technicians, potentially leading to higher costs and longer turnaround times for non-Apple parts. They prioritize original parts. | Variable, often longer for complex repairs. | High, with significant markups on parts and labor. |

| Dell | Dell typically utilizes a network of authorized repair centers. This can provide more accessibility for repairs, but may involve third-party technicians with varying levels of expertise. | Generally shorter than Apple, but can fluctuate based on repair complexity and location. | Moderate, with costs depending on the extent of the damage. |

| Lenovo | Lenovo employs a similar model to Dell, relying on a network of authorized repair centers. They frequently offer various repair options, including mail-in services and in-store options. | Generally comparable to Dell, but with some variation based on the chosen repair method. | Moderate, with costs dependent on the severity of the issue and the chosen repair method. |

Customer Service Experiences

Customer service extends beyond the mechanics of repair. It encompasses communication, responsiveness, and the overall feeling of support during the repair process. This can significantly impact customer satisfaction.

- Apple often receives high praise for its intuitive online support resources and streamlined repair processes. However, the cost and limited accessibility of authorized repair centers can be a downside.

- Dell’s customer service is often viewed as accessible and efficient, with multiple avenues for communication and resolution. This approach typically leads to faster response times and better communication.

- Lenovo generally provides a similar level of accessibility to customer service channels as Dell, but individual experiences may vary based on the specific repair center or representative.

Employee Training and Support

The quality of employee training directly influences the effectiveness of the repair process. Well-trained technicians are equipped to handle a wider range of issues and provide better service.

- Apple’s technicians often undergo rigorous training programs, ensuring a high level of technical expertise. This, combined with strict adherence to repair procedures, leads to consistently high-quality repairs.

- Dell’s repair technicians generally receive adequate training, but the varying levels of expertise among third-party technicians can create inconsistencies in the quality of repairs.

- Lenovo’s training programs often target efficiency and proper diagnostic procedures. However, the extent of training and support for specific models may differ.

Challenges and Advantages

Each brand presents unique challenges and advantages for repair facilities. These factors can impact efficiency, cost, and overall customer experience.

- Apple’s strict adherence to proprietary parts can be a challenge, as finding compatible parts can be difficult. The high cost of repairs can also be a significant disadvantage for customers.

- Dell’s reliance on a network of authorized repair centers offers greater accessibility. However, the quality of repair may vary based on the specific technician and the complexity of the issue.

- Lenovo’s diverse repair options can be advantageous for customers seeking flexibility and cost-effectiveness. The availability of third-party parts can potentially lead to quicker turnaround times.

Final Conclusion: Csat Solutions Repair Facility Texas Apple Macbook Dell Lenovo Working Conditions Employees

Ultimately, the success of CSAT repair facilities in Texas depends on a harmonious blend of employee well-being and customer satisfaction. The analysis of working conditions, employee satisfaction, and repair facility operations provides valuable insights for businesses aiming to thrive in this competitive market. Future trends and technological advancements are likely to shape the industry, influencing employee roles and operational efficiency.

A strong focus on employee satisfaction and customer-centric practices will be vital for long-term success.