Car company tariff response price layoff factory impacts everything from pricing strategies to factory closures. Tariffs significantly alter a car company’s cost structure, affecting the final price consumers pay. This analysis explores how different car segments, from luxury to economy, are impacted, along with the effects on supply chains and potential workforce reductions. The discussion also examines how companies adjust prices, the role of layoffs in the automotive industry, and the various strategies factories use to adapt to these changes.

The ripple effect of tariffs extends beyond the immediate impact on car companies. From raw materials to finished vehicles, the entire supply chain feels the pressure. This analysis delves into the complex interplay of global trade dynamics and the automotive industry, examining past examples of tariff-related issues and predicting potential future scenarios. Understanding these factors is crucial for anyone invested in the automotive industry or interested in global trade policies.

Tariff Impact on Car Companies

Tariffs, taxes imposed on imported goods, significantly impact car companies by altering pricing strategies, cost structures, and supply chains. Understanding these effects is crucial for evaluating the competitive landscape and future prospects of the automotive industry. The ripple effect of tariffs extends far beyond the initial import duties, influencing everything from the retail price of a car to the livelihoods of workers in the supply chain.Tariffs directly increase the cost of imported components, raw materials, and finished vehicles.

This added expense is often passed on to consumers, leading to higher prices at the retail level. The relationship between tariff levels and car manufacturers’ cost structures is demonstrably linear, with higher tariffs leading to proportionally higher costs. This can make domestic production more attractive and incentivize companies to invest in local manufacturing facilities.

Tariff Effects on Pricing Strategies

Car companies adjust pricing strategies in response to tariffs to maintain profitability and competitiveness. They may absorb some of the tariff costs to protect market share or raise prices to compensate for the increased expenses. Strategies may also include negotiating with suppliers to reduce costs, shifting production to reduce reliance on imported components, or even considering a temporary reduction in production volume.

Tariff Impact on Cost Structures

Tariff levels directly impact a car company’s cost structure by increasing the price of imported parts and materials. A 10% tariff on imported steel, for example, will directly increase the cost of producing a vehicle. The impact is magnified if many components are imported. This often leads to a chain reaction, affecting the prices of other components and eventually the final vehicle price.

Tariff Impact on Different Car Segments

The impact of tariffs varies across different car segments. Luxury car manufacturers, often relying heavily on imported components, may experience a larger percentage increase in costs compared to economy car manufacturers. Luxury car segments may also see a greater effect on the overall pricing due to the higher value of the vehicle. Economy car manufacturers, with a potentially higher reliance on locally sourced components, might experience a more muted effect, but still see a change in their cost structure.

Tariff Effects on Supply Chains

Tariffs disrupt the delicate balance of global supply chains. Raw materials, such as steel and aluminum, and component parts from various countries, face increased costs and delays due to tariffs. This can result in shortages, production delays, and increased costs for car manufacturers. The effects of tariffs can be felt across the entire supply chain, impacting suppliers, distributors, and retailers.

Comparison of Tariff Impacts Across Countries

| Country | Tariff Rate on Imported Cars | Effect on Car Prices | Effect on Domestic Production |

|---|---|---|---|

| United States | Varying, depending on the specific car and origin | Increased prices for imported cars | Incentivizes investment in domestic production facilities |

| European Union | Varying, depending on the specific car and origin | Increased prices for imported cars | Encourages investment in local production and sourcing |

| Japan | Varying, depending on the specific car and origin | Increased prices for imported cars | Incentivizes production in Japan and other countries with lower tariffs |

This table illustrates the diverse impacts of tariffs on car pricing across different countries. Note that specific tariff rates and their effects can change frequently.

Price Adjustments in Response to Tariffs: Car Company Tariff Response Price Layoff Factory

Car companies face significant challenges when tariffs are imposed on imported components or finished vehicles. These tariffs increase the cost of production, impacting profitability and requiring strategic responses. The decision of how to adjust prices is complex, balancing the need to maintain competitiveness with the desire to retain market share.Price adjustments are a critical aspect of a company’s response to tariffs.

They directly impact consumer perception and market share. Companies must carefully consider the interplay between cost increases, market demand, and competitor pricing strategies to determine the optimal price adjustment strategy. This often involves a combination of factors, including absorption of some costs, passing on increases to consumers, and altering production strategies.

Strategies for Price Adjustments

Car manufacturers employ various strategies to absorb or pass on tariff costs. Some common strategies include reducing profit margins, negotiating with suppliers to mitigate cost increases, and implementing production efficiencies to reduce the overall cost of manufacturing. The ultimate strategy often depends on the magnitude of the tariff, the overall economic climate, and the company’s competitive position in the market.

Impact on Final Retail Price

Tariff increases directly translate to higher costs for car manufacturers. These costs are often passed on to consumers in the form of higher retail prices. The extent of the price increase depends on several factors, including the magnitude of the tariff, the company’s ability to absorb the cost, and the overall demand for the vehicle. A significant tariff on a key component, for example, could result in a substantial price increase for the final product.

Factors Influencing Cost Absorption or Passing On

Several factors influence a car company’s decision to absorb tariff costs or pass them on to consumers. The company’s profit margins, the overall market demand for the vehicle, and the pricing strategies of competitors all play crucial roles. A company with substantial profit margins might absorb a portion of the tariff cost to maintain market share. Conversely, a company facing intense competition might choose to pass on the entire tariff cost to consumers.

Another crucial factor is the company’s long-term market strategy. A company aiming for long-term growth might choose to absorb some costs to maintain market share and brand reputation.

Examples of Past Reactions to Tariff Increases

In the past, various car companies have reacted differently to tariff increases. Some companies have absorbed a portion of the increased costs to maintain sales volume and market share, while others have opted to pass on the full increase to consumers. For instance, after the imposition of tariffs on steel imports in the United States, some car manufacturers absorbed a portion of the cost increase to avoid significant price increases.

Car companies are reacting to tariffs by adjusting prices and, unfortunately, laying off factory workers. This economic ripple effect is impacting the gaming industry too, as evidenced by the recent delay of the Advance Wars reboot, a popular strategy game. The nintendo advance wars release delay 1 2 reboot camp highlights how interconnected these sectors are.

Ultimately, these price adjustments and job losses in the automotive sector are causing a domino effect, potentially impacting consumer spending and demand in other industries.

Other companies adjusted their pricing models to offset the impact of tariffs. This variability in reaction demonstrates the complex interplay of factors influencing price adjustment strategies.

Comparison of Price Adjustment Strategies

| Car Manufacturer | Strategy | Impact on Retail Price | Rationale |

|---|---|---|---|

| Company A | Absorbed a portion of the tariff | Retail price increased slightly | Maintained market share and brand image |

| Company B | Passed on the entire tariff to consumers | Retail price increased significantly | Maintained profit margins despite higher costs |

| Company C | Negotiated with suppliers to mitigate cost increases | Retail price increase minimized | Reduced cost burden by directly addressing the tariff’s impact on components |

Layoffs in the Automotive Industry

The automotive industry, a cornerstone of many global economies, is highly susceptible to external pressures. Tariffs, in particular, can trigger a cascade of events, impacting pricing, production, and ultimately, employment. This section explores the intricate relationship between tariffs, pricing pressures, and the potential for job losses within the automotive sector.Tariffs, by increasing the cost of imported parts and finished goods, directly influence pricing strategies for automobiles.

Manufacturers often pass on these increased costs to consumers, leading to higher prices. This, in turn, can reduce demand, especially if consumers are sensitive to price fluctuations. The reduced demand can force manufacturers to cut production, leading to workforce reductions.

Correlation Between Tariffs, Pricing, and Job Losses

The relationship between tariffs, pricing, and job losses is a direct one. Higher tariffs lead to increased production costs, forcing companies to either absorb these costs, increase prices, or reduce production. If companies choose to increase prices, demand may decrease, leading to lower sales and the need for layoffs. Conversely, if companies reduce production, they may need to cut back on their workforce to match the reduced output.

This is especially true in industries with complex supply chains, where tariffs on components can have a ripple effect throughout the manufacturing process.

Recent car company tariff responses have led to fluctuating prices and, unfortunately, layoffs at some factories. This is a complex issue, and it’s interesting to consider how these economic pressures might relate to Elon Musk’s vision for Tesla, which is to move beyond just being a car company, focusing on a broader energy and technology platform. Why Elon Musk wants Tesla to stop being a car company highlights this ambition.

Ultimately, these tariff-driven price adjustments and factory downsizing within the car industry are proving to be significant challenges for the companies involved.

Impact on Factory Production and Workforce Size

Tariffs can significantly impact factory production. If tariffs make imported parts more expensive, factories may have to reduce production to maintain profitability. Reduced production often translates directly to job losses, particularly in roles related to manufacturing and assembly. The impact can vary greatly depending on the specific tariff, the company’s ability to absorb increased costs, and the overall economic climate.

Impact on Different Parts of the Automotive Supply Chain

The automotive supply chain is interconnected, and tariffs affect different segments differently. Manufacturing plants, which assemble vehicles, are immediately affected by reduced production. Distribution centers and dealerships may experience lower sales volumes, leading to layoffs in those areas. Sales teams may see a reduction in commission-based income. Tariffs also affect the suppliers of raw materials and components, who may experience reduced demand and potentially need to lay off employees.

Examples of Past Layoffs Related to Global Trade Policies

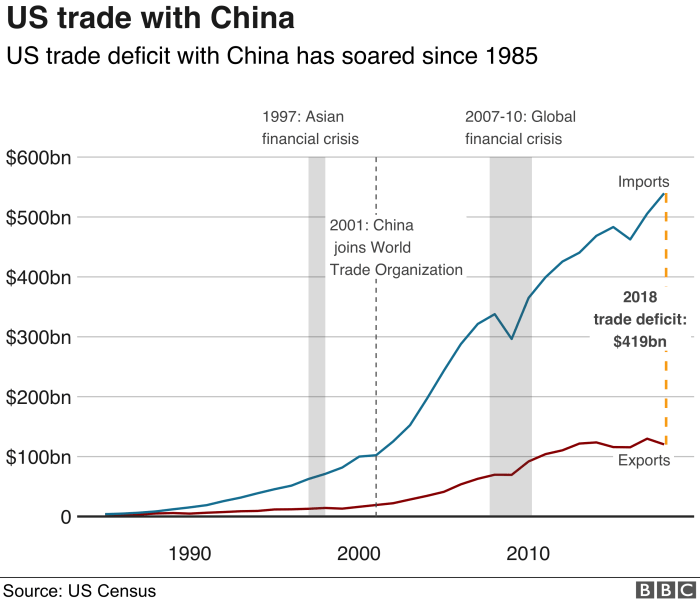

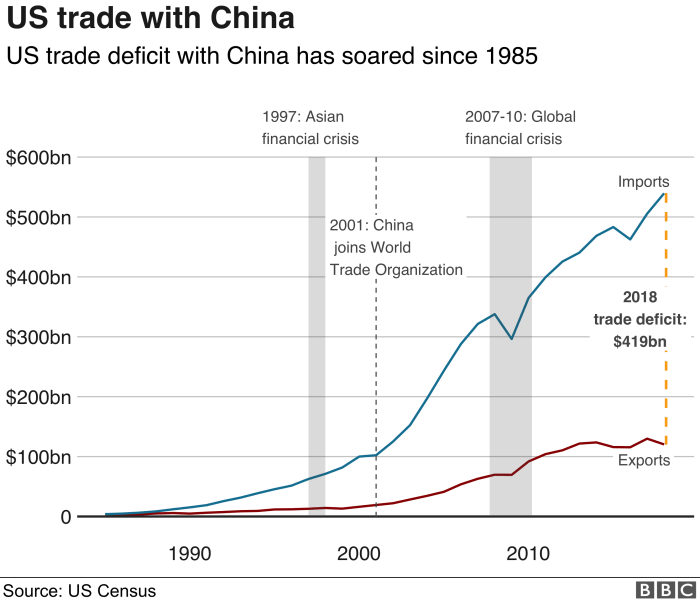

Historically, several instances of layoffs in the automotive industry have been linked to global trade disputes and tariffs. For example, the 2018 imposition of tariffs by the United States on imported steel and aluminum prompted concern within the automotive sector regarding potential job losses. Similarly, the North American Free Trade Agreement (NAFTA) renegotiation and resulting trade policies had an effect on the automotive industry, impacting jobs in certain regions.

Impact on Local Communities and Economies

Layoffs in the automotive industry can have a significant impact on local communities and economies. Loss of jobs often translates to a decrease in consumer spending, which can negatively affect local businesses. Unemployment can increase, leading to social and economic hardship for individuals and families. The loss of tax revenue from the reduced workforce can also negatively affect government services.

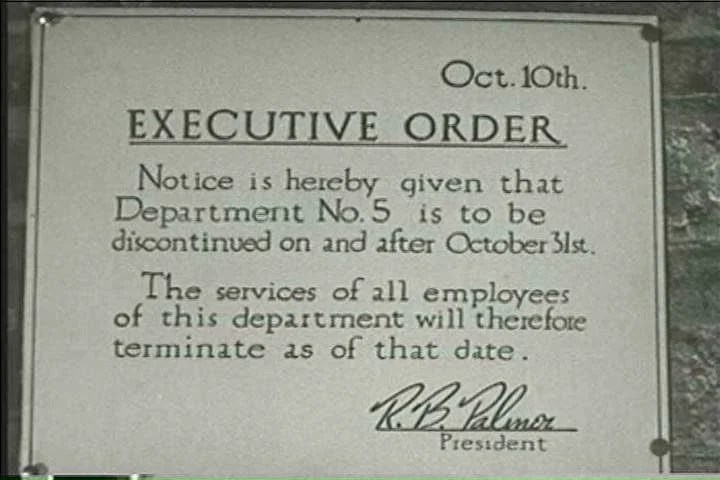

Scenarios for Factory Closures and Worker Displacement

The potential for factory closures and worker displacement due to tariffs is a serious concern. If a manufacturer faces significant cost increases and cannot adjust pricing or production, they may be forced to close a factory or significantly reduce operations. This can result in substantial job losses, and the impacted workers may struggle to find alternative employment. The process of finding new employment can be particularly challenging in areas with a high concentration of automotive industry workers.

Comparison of Layoffs Across Car Companies

Unfortunately, precise data on layoffs specifically due to tariff fluctuations is difficult to obtain and often not readily publicized. Publicly available data frequently focuses on overall company performance, making it hard to isolate the impact of tariffs. However, in situations where tariffs significantly impacted a company’s bottom line, it was often reported in news outlets and financial publications.

Factory Responses to Trade Policies

Car manufacturers face significant challenges when navigating complex international trade policies. Tariffs, quotas, and other regulations can dramatically shift production costs and market dynamics, prompting car factories to adapt their strategies to maintain profitability and competitiveness. These adjustments can range from shifting production lines to completely relocating manufacturing facilities. Understanding these responses is crucial for evaluating the long-term impact of trade policies on the automotive industry.Car factories employ a range of strategies to mitigate the negative effects of trade policies.

These strategies are crucial for maintaining competitiveness in a global market. They are constantly evaluating and adjusting their production models to optimize efficiency and minimize costs, especially when confronted with tariffs. This often involves optimizing supply chains, exploring alternative sourcing options, and investing in technology to improve production processes.

Strategies for Adjusting Production

Factories often adjust production to maintain competitiveness in the face of tariff changes. This includes optimizing existing production lines, exploring alternative sourcing options for parts, and even temporarily suspending production in certain locations. These adjustments are not static; they are dynamic and require ongoing monitoring and adaptation to maintain profitability. Furthermore, investments in technology can enhance efficiency and lower production costs, enabling manufacturers to remain competitive even with tariffs in place.

Factors Influencing Factory Relocation Decisions

Several factors influence a factory’s decision to relocate. These include the magnitude and duration of tariffs, the availability of skilled labor in alternative locations, the cost of transportation, and government incentives offered in potential new locations. Furthermore, proximity to raw materials and access to key markets also play significant roles in the relocation process. Companies carefully weigh the costs and benefits of relocation to ensure it aligns with their long-term strategic goals.

Relocating Manufacturing Facilities

Relocating manufacturing facilities is a complex and multifaceted process. It involves meticulous planning, legal considerations, and significant financial investment. The process often includes identifying suitable locations, negotiating with local governments, and training workers in the new facility. Environmental regulations and labor laws in different countries are also crucial factors to consider during the relocation process.

Examples of Factory Adjustments

In response to tariffs, some car manufacturers have shifted production lines to regions with lower tariffs. Others have diversified their supply chains, sourcing components from multiple countries to reduce dependence on a single region. Some have also invested in automation to improve efficiency and offset higher labor costs. For instance, a manufacturer might increase robotic automation in a facility in a higher-tariff region to maintain cost competitiveness in the face of increased production costs.

Summary Table of Factory Strategies

| Strategy | Description | Example |

|---|---|---|

| Shifting Production Lines | Moving production to areas with lower tariffs or fewer trade restrictions. | A company relocating production from a country with high tariffs to one with low tariffs. |

| Diversifying Supply Chains | Sourcing parts from multiple countries to reduce reliance on a single region. | A company procuring components from multiple suppliers in different countries. |

| Investing in Automation | Implementing robots and automated systems to enhance efficiency and reduce labor costs. | A company increasing robotic automation in a manufacturing plant. |

| Relocating Facilities | Moving the entire manufacturing facility to a new location. | A company moving its production line from a high-tariff country to a low-tariff country. |

Impact on Consumer Demand

Tariffs on automobiles have a profound impact on consumer purchasing decisions, affecting affordability, preferences, and ultimately, the entire car market. Understanding these effects is crucial for both consumers and manufacturers alike. This analysis will delve into how tariffs influence consumer choices, considering price increases, consumer preferences, and overall market dynamics.

Influence on Consumer Purchasing Decisions

Tariffs directly impact the cost of imported vehicles, leading to higher prices for consumers. This price increase can significantly influence consumer purchasing decisions. Consumers may opt for more affordable alternatives, either domestically produced cars or used vehicles, if the price difference is substantial. Furthermore, the perceived value of the imported car, compared to the price increase, plays a key role in consumer choices.

The decision to purchase a specific car model is often a complex calculation weighing factors such as price, quality, features, and brand reputation.

Car companies are responding to rising tariffs by adjusting prices, leading to layoffs and factory closures. It’s a tough economic climate, and these moves are sadly becoming common. This isn’t unlike what’s happening in the entertainment industry, where Disney+ is raising prices, including the ad tier and other subscription options, as detailed in this helpful article on the topic: disney plus hike prices the ad tier and everything else to know.

Ultimately, these price hikes and layoffs across various sectors are indicative of broader economic pressures, and companies are struggling to adapt to changing market conditions.

Impact of Tariff-Induced Price Increases on Affordability

Tariff-induced price increases directly reduce the affordability of cars, especially for those on a budget. A significant price hike can make a vehicle unaffordable for a considerable portion of the market. For example, if a popular imported model’s price rises by 20%, it becomes less accessible to those who previously considered it a viable option. This can force consumers to either seek alternative transportation or delay purchasing a vehicle altogether.

The affordability issue is further exacerbated for those already struggling with economic pressures.

Factors Influencing Consumer Demand for Imported or Domestically Produced Cars

Consumer demand for both imported and domestically produced cars is shaped by a multitude of factors. Beyond price, factors such as brand reputation, perceived quality, fuel efficiency, safety features, and available financing options play crucial roles. Consumers often weigh these factors alongside the price when making their purchasing decisions. For instance, a domestic car with a strong reputation for reliability might appeal to consumers despite a potentially higher price compared to a comparable imported model.

Potential Shifts in Consumer Preferences in Response to Tariff Changes

Tariff changes can induce significant shifts in consumer preferences. Consumers may increasingly favor domestically produced cars to avoid higher import costs. The perception of supporting domestic industries can also influence preferences. Additionally, if the price difference between imported and domestically produced cars becomes substantial, consumers may shift their focus to vehicles with more readily available, and potentially cheaper, alternatives.

Impact of Tariffs on the Overall Car Market, Including Sales Volume and Growth

Tariffs can significantly impact the overall car market, affecting sales volume and growth. A rise in prices, triggered by tariffs, can lead to a decrease in sales, particularly for imported vehicles. This decrease in demand can negatively affect the growth of the overall market, as consumers may delay or cancel purchases. The impact can be more pronounced in markets where imported cars represent a substantial portion of sales.

Consumer Reaction to Price Changes Based on Different Tariff Levels

| Tariff Level | Price Increase (%) | Potential Consumer Reaction |

|---|---|---|

| Low (e.g., 5%) | Minor | Limited impact on demand; consumers may adjust slightly. |

| Medium (e.g., 10-15%) | Moderate | Some consumers may seek alternatives; sales may decrease moderately. |

| High (e.g., 20%+ | Significant | Significant decrease in demand; consumers strongly affected; potential shift to domestically produced alternatives. |

Global Trade Dynamics and Automotive Industry

The automotive industry, a global powerhouse, is deeply intertwined with international trade. Tariffs, trade wars, and fluctuating exchange rates all significantly impact production costs, pricing strategies, and ultimately, consumer access to vehicles. Understanding these dynamics is crucial for comprehending the complexities facing car manufacturers today.

Broader Implications of Tariffs on Global Trade, Car company tariff response price layoff factory

Tariffs, essentially taxes on imported goods, can disrupt global supply chains. When tariffs are imposed on imported car parts or finished vehicles, the cost of production rises for manufacturers. This increased cost is often passed on to consumers in the form of higher prices, potentially reducing demand and impacting market share. Furthermore, retaliatory tariffs from other countries can create a domino effect, escalating trade tensions and hindering economic growth.

Comparison of Car Manufacturer Responses to Tariffs

Different car manufacturers have employed varying strategies to cope with tariffs. Some have shifted production to countries with lower tariffs, while others have invested in local sourcing of parts to minimize the impact. Others have focused on developing more resilient supply chains, diversifying their sourcing and potentially increasing inventory to mitigate the effects of potential disruptions. The choice of strategy often depends on the specific manufacturer’s global footprint, its dependence on international supply chains, and its financial resources.

Implications of Trade Wars on Competitiveness

Trade wars, characterized by escalating tariffs and retaliatory measures, can significantly impact the competitiveness of car companies in various markets. Companies facing tariffs in multiple regions may find themselves at a disadvantage compared to competitors operating in less-restricted environments. This could lead to a decline in market share, reduced profitability, and even factory closures in affected regions. For example, the 2018-2019 trade war between the US and China resulted in uncertainty and increased costs for automakers operating in both markets.

Impact of Tariffs on International Supply Chains

Tariffs can create significant disruptions to international supply chains. The complexity of modern vehicle manufacturing often involves parts sourced from various countries. Tariffs increase the cost of these components, making it more expensive to assemble vehicles. This can lead to delays in production, reduced output, and potentially higher prices for consumers. Manufacturers must carefully assess the potential impact of tariffs on their sourcing strategies to mitigate these risks.

Impact of Different Trade Agreements on the Automotive Industry

Trade agreements, such as NAFTA (now USMCA) and the EU’s common market, have significantly influenced the automotive industry. These agreements often reduce or eliminate tariffs on vehicles and parts, fostering trade and stimulating production. The removal of trade barriers can lead to economies of scale, lower production costs, and greater access to markets. However, the renegotiation or termination of such agreements can disrupt established supply chains and introduce uncertainty into the industry.

Influence of Global Trade Dynamics on the Car Industry

| Factor | Impact on Car Industry |

|---|---|

| Tariffs | Increased production costs, higher prices, reduced demand, supply chain disruptions. |

| Trade Wars | Reduced competitiveness, potential for market share loss, factory closures. |

| Trade Agreements | Reduced tariffs, economies of scale, access to larger markets. |

| Exchange Rate Fluctuations | Impact on import/export costs, affecting profitability. |

| Geopolitical Events | Disruptions to supply chains, increased uncertainty. |

Final Summary

In conclusion, car company tariff response price layoff factory presents a multifaceted challenge. From adjusting pricing strategies to potentially relocating factories, companies must navigate complex global trade policies. Layoffs, factory closures, and shifts in consumer demand are all potential outcomes. This analysis highlights the interconnectedness of the global automotive industry and the far-reaching consequences of tariffs on businesses and consumers alike.

The discussion reveals the significant impact of trade policies on the industry’s future.