With Belkin ventilator partnership fda university of illinois flexvent, a groundbreaking collaboration is set to reshape the medical device landscape. This partnership between Belkin, renowned for its consumer electronics design, and the University of Illinois, creators of the innovative FlexVent ventilator, promises a significant leap forward in respiratory care. We’ll delve into the specifics of this collaboration, exploring the technical innovations, regulatory hurdles, and potential market impact of this ambitious project.

The partnership involves Belkin bringing its expertise in design and manufacturing to the FlexVent, aiming to enhance its user-friendliness and efficiency. The University of Illinois will contribute the cutting-edge ventilator technology, while navigating the intricate FDA regulatory process. This collaboration presents a unique opportunity to streamline the development and deployment of advanced respiratory support systems.

Introduction to the Belkin Ventilator Partnership

The Belkin ventilator partnership with the University of Illinois FlexVent represents a significant collaboration in the medical technology sector. This joint effort aims to enhance ventilator design and accessibility, potentially revolutionizing critical care in various settings. The partnership leverages Belkin’s expertise in consumer electronics and product design with the University of Illinois’s research capabilities in respiratory medicine.This collaboration is expected to produce innovative and user-friendly ventilators, addressing potential challenges in accessibility and usability, ultimately improving patient outcomes.

The specific focus areas will likely include design optimization for ease of use and maintenance, and potentially exploring cost-effective manufacturing methods. It promises to be a dynamic partnership that could significantly impact the future of critical care.

Specific Roles and Responsibilities

The collaboration involves distinct roles for each partner. Belkin’s contribution likely centers on the industrial design, manufacturing, and supply chain aspects of the project. This includes translating research findings into practical and marketable products. The University of Illinois FlexVent team will likely focus on the scientific and engineering research, validation, and testing of the ventilator design. Their core responsibilities will encompass the design and development of the underlying technology and ensuring adherence to safety and performance standards.

Potential Benefits and Drawbacks

This partnership holds considerable potential benefits. Increased accessibility of advanced ventilation technology is a significant possibility, with the potential for cost-effective production. Improved user experience through a consumer-centric design is another key benefit. However, there might be challenges in the integration of diverse expertise, potential delays in product development, and the need for robust intellectual property protection.

Successfully addressing these challenges is critical for the long-term success of the partnership.

Key Personnel

The success of this partnership relies on the expertise of the key personnel involved. A dedicated team of engineers, researchers, and product managers from both Belkin and the University of Illinois FlexVent will be essential to navigate the complexities of the project. Their collective experience and collaborative spirit will be instrumental in overcoming potential obstacles and achieving project goals.

| Organization | Role | Name |

|---|---|---|

| Belkin | Chief Product Officer | [Name Redacted] |

| University of Illinois FlexVent | Lead Research Engineer | [Name Redacted] |

| Belkin | Manufacturing Lead | [Name Redacted] |

| University of Illinois FlexVent | Principal Investigator | [Name Redacted] |

Overview of the University of Illinois FlexVent

The University of Illinois FlexVent represents a significant advancement in respiratory support technology. Its innovative design and modularity promise enhanced patient care and improved outcomes, particularly in dynamic situations. This overview delves into the technical specifications, intended applications, and unique features of the FlexVent.The FlexVent ventilator is designed for versatile application in various healthcare settings, aiming to meet the needs of a broad spectrum of patients.

Its adaptable nature is key to providing optimal respiratory assistance, from general use to specialized scenarios. The device is also geared toward ease of use and maintenance, contributing to its potential for wider adoption.

Technical Specifications and Design Features

The FlexVent’s design prioritizes modularity and adaptability. This modularity allows for quick and easy configuration adjustments based on patient needs. Key design features include a lightweight yet robust construction, facilitating portability and enabling use in diverse environments. The device’s compact size further contributes to ease of transportation and storage. Precise control mechanisms allow for fine-tuning of ventilation parameters.

An intuitive user interface simplifies operation, minimizing the learning curve for healthcare professionals.

Intended Application and Target User Groups

The FlexVent is designed for a wide range of acute and chronic respiratory care needs. Its modularity allows for customization across various patient populations. This includes patients requiring mechanical ventilation in intensive care units (ICUs), emergency rooms (ERs), and even in pre-hospital settings. Target user groups encompass critical care specialists, emergency medical technicians (EMTs), and nurses, ensuring versatility in deployment and usage.

The Belkin ventilator partnership with the FDA and University of Illinois Flexvent project is fascinating, especially given recent developments in innovative ventilation technology. It’s interesting to consider how this might relate to the work of Apple executives like Eddy Cue, Siri, and Craig Federighi, particularly in the context of their experience with user-friendly interfaces and innovative design. apple eddy cue siri craig federighi are known for pushing the boundaries of technology, and their insights into seamless user experiences might offer valuable perspectives on improving ventilation systems.

Ultimately, the goal of the Belkin ventilator partnership remains the same – to deliver safer and more effective solutions for healthcare needs.

Innovative Aspects Compared to Other Ventilators

The FlexVent’s innovative design lies in its adaptability. Unlike traditional ventilators with fixed configurations, the FlexVent’s modular design allows for adjustments to specific patient needs. This adaptability translates into enhanced treatment options and potentially improved patient outcomes. This responsiveness can prove particularly beneficial in dynamic situations where rapid changes in a patient’s condition require immediate adjustments to ventilation parameters.

Comparison to Similar Products

| Feature | FlexVent | Competitor A | Competitor B |

|---|---|---|---|

| Weight (kg) | ~8 | ~12 | ~10 |

| Dimensions (cm) | 50 x 30 x 20 | 60 x 40 x 30 | 55 x 35 x 25 |

| Modular Design | Yes | No | Limited |

| Portability | High | Medium | Medium |

| Ease of Use | High | Medium | Medium |

| Cost | Estimated $XX,000 | Estimated $YY,000 | Estimated $ZZ,000 |

Note: Competitor A, B, and cost figures are illustrative and do not represent actual product specifications or pricing. The table provides a general comparison based on potential features and characteristics.

Belkin’s Contribution and Expertise

Belkin, renowned for its innovative consumer electronics, brings a wealth of experience in product design and engineering to this partnership. Their expertise extends beyond the typical consumer market, encompassing the development of durable, user-friendly, and high-performance devices. This translates directly to the crucial aspects of ventilator design, potentially enhancing the FlexVent’s usability and reliability. Their focus on meticulous engineering and user-centric design principles will be instrumental in improving the overall patient experience.Belkin’s contribution goes beyond simple design aesthetics; it encompasses a deep understanding of material science, component integration, and user interface optimization.

Their track record of success in developing high-quality, robust products suggests they will bring significant value to the FlexVent project, potentially leading to a more efficient and reliable medical device.

Belkin’s Proven Track Record

Belkin’s history showcases a commitment to quality and user-centric design. Their product portfolio, spanning from chargers and headphones to power adapters and accessories, consistently demonstrates an understanding of consumer needs. This understanding is crucial in translating user feedback into design improvements, leading to higher user satisfaction and product longevity. The experience gained from producing millions of devices worldwide suggests a robust process for quality control and iterative design improvements.

Specific Technologies and Skills

Belkin’s involvement will likely include several key technological contributions. Their expertise in advanced material science will likely be crucial in optimizing the FlexVent’s components for durability and resistance to environmental factors. Furthermore, Belkin’s proficiency in creating intuitive user interfaces will improve the device’s ease of use for medical professionals and potentially even patients, which will reduce the risk of mistakes and enhance patient care.

Their understanding of power management systems will be vital in ensuring the device operates reliably and efficiently, which is paramount in a critical care setting. Furthermore, Belkin’s robust supply chain management will ensure consistent availability of components, minimizing delays in production and maintenance.

Examples of Belkin’s Design Successes

| Product Category | Product Name (Example) | Key Design Feature | Impact |

|---|---|---|---|

| Charging Accessories | Fast Charging Cable | Optimized cable design for faster charging speeds, reduced cable wear | Increased user satisfaction due to improved performance, reduced downtime |

| Wireless Headphones | True Wireless Earbuds | Ergonomic ear tip design, enhanced noise cancellation | Improved user comfort and performance, leading to high market adoption |

| Power Adapters | Compact Travel Adapter | Compact and lightweight design, international voltage compatibility | Increased portability and usability, expanded market reach |

These examples demonstrate Belkin’s ability to translate consumer needs into innovative product designs. This experience is directly applicable to the needs of a medical device, ensuring that the FlexVent is designed to meet the specific demands of healthcare professionals.

FDA Regulatory Considerations

Navigating the FDA’s regulatory landscape is crucial for any medical device partnership, especially one involving a novel ventilator like the FlexVent. Understanding the specific hurdles and procedures is essential for ensuring a smooth and compliant path to market. This section delves into the FDA’s regulatory framework, highlighting potential challenges and the approval process.The FDA’s stringent regulations ensure patient safety and efficacy of medical devices.

Compliance with these regulations is paramount for any company seeking to introduce a new device to the market. Failure to adhere to these standards can result in significant delays, legal repercussions, and reputational damage.

FDA’s Regulatory Framework for Medical Devices

The FDA classifies medical devices based on their risk level. This classification directly impacts the regulatory requirements. Class I devices pose the lowest risk and require the least stringent controls. Class II devices present a moderate risk and necessitate more extensive pre-market submissions. Class III devices, the highest risk category, typically require pre-market approval.

The FlexVent, a life-sustaining medical device, is likely to fall into Class III, requiring a rigorous review process.

The Belkin ventilator partnership with the FDA and the University of Illinois Flexvent project is really interesting, but honestly, I’m more drawn to the new tech in smartphones these days. For example, the new TCL 20 Pro 5G boasts a stunning 6.67-inch AMOLED display with HDR10 support, which is pretty impressive. the new TCL 20 Pro 5G has a 6 67 inch amoled display with HDR10 support While I appreciate the medical advancements, I’m just amazed at the progress in mobile displays.

Perhaps the same innovation will one day be applied to the Flexvent project for enhanced user experience, and to give the users better feedback in a better and easier way to use.

Specific Regulatory Hurdles for the Partnership

The partnership between Belkin and the University of Illinois might face specific regulatory challenges due to the novel nature of the FlexVent. The FDA will scrutinize any modifications Belkin makes to the original design, assessing their impact on the device’s safety and efficacy. The modifications must be thoroughly documented and justified. This includes the materials used, manufacturing processes, and intended use cases.

Potential issues could stem from integrating Belkin’s expertise with the existing FlexVent design, requiring extensive clinical trials and data analysis to validate safety and efficacy.

Procedures for Obtaining FDA Approval for the FlexVent

Obtaining FDA approval for a Class III device like the FlexVent involves several crucial steps. The process is multifaceted, requiring significant resources and expertise. This process typically begins with a thorough risk analysis and the development of a comprehensive design control plan.

Pre-market Approval (PMA)

The FDA’s pre-market approval (PMA) process is the most stringent route for gaining approval. It requires extensive clinical trials, data analysis, and validation to demonstrate safety and effectiveness. This process demands extensive evidence, including animal studies, in-vitro studies, and human clinical trials.

510(k) Premarket Notification

The 510(k) process, an alternative pathway, is used when a device is substantially equivalent to a legally marketed device (predicate device). For a modified FlexVent, this pathway might be less suitable if the modifications significantly alter the device’s performance or characteristics.

Table: Steps Required for FDA Approval

| Step | Description |

|---|---|

| 1. Initial Assessment | Identify the device class and appropriate regulatory pathway. |

| 2. Design Control Plan | Develop a detailed plan for design, manufacturing, and testing. |

| 3. Pre-clinical Studies | Conduct animal studies and in-vitro testing to evaluate safety and efficacy. |

| 4. Clinical Trials | Conduct human clinical trials to demonstrate the device’s safety and efficacy. |

| 5. Pre-market Submission | Submit a comprehensive application to the FDA, including all supporting documentation. |

| 6. FDA Review | The FDA reviews the application, conducting audits and inspections. |

| 7. Approval/Rejection | The FDA approves or rejects the device, potentially with conditions or requests for additional data. |

Potential Market Impact

The Belkin-University of Illinois FlexVent partnership holds significant potential for reshaping the portable ventilator market. This collaboration promises to bring a more accessible and potentially more affordable solution to the critical care arena, particularly in underserved regions and situations requiring rapid deployment. The anticipated market impact is multifaceted, impacting existing players, driving innovation, and potentially altering the overall landscape of respiratory support.

Projected Market Size and Growth Potential

The portable ventilator market is experiencing substantial growth, driven by increasing demand for medical devices capable of supporting patients in various settings, from home care to disaster relief. Predicting the precise market size for the FlexVent is challenging, as it hinges on factors such as pricing, regulatory approvals, and consumer acceptance. However, projections suggest a substantial growth opportunity.

The partnership between Belkin and the University of Illinois, leveraging Belkin’s expertise in consumer electronics and the University’s technological prowess, could significantly contribute to the market share growth. The FlexVent’s potential for wider adoption, particularly in developing countries and for home care applications, could contribute to a considerable market expansion. This expansion hinges on a balance of affordability, performance, and user-friendliness.

Potential Competition and Challenges

The portable ventilator market is already populated by established players, each with their own strengths and weaknesses. Competition from established brands and newer entrants will undoubtedly be fierce. Challenges include maintaining quality control, securing regulatory approvals, and competing on price and performance. The FlexVent faces the challenge of differentiating itself from existing products and establishing its own market niche.

The focus on ease of use and potential cost-effectiveness will be crucial for successful market penetration. Potential challenges include securing reliable supply chains for components, managing production volumes, and addressing consumer expectations for advanced features.

Potential Impact on Existing Ventilator Manufacturers

The emergence of the FlexVent, especially if it gains significant market traction, could impact existing ventilator manufacturers in several ways. Some manufacturers might see a shift in consumer demand towards more portable and accessible solutions. The impact could range from modest adjustments to their product portfolios to significant restructuring, depending on the success of the FlexVent. The market will likely witness a diversification of the market segments, with the FlexVent potentially creating a new category for consumers.

Established manufacturers might need to adapt their strategies to remain competitive, potentially by developing comparable portable solutions or by focusing on niche segments within the market.

Market Trends and Forecasts

| Year | Market Trend | Projected Market Size (USD millions) | Market Growth (%) |

|---|---|---|---|

| 2023 | Steady growth in demand for portable ventilators | $100 | 5% |

| 2024 | FlexVent launch, initial market penetration | $120 | 20% |

| 2025 | Increased adoption of FlexVent, market share gain | $180 | 50% |

| 2026 | Continued growth, competition intensifies | $300 | 67% |

This table represents a potential market trend analysis for the FlexVent. The projected figures are estimations, and actual market performance may differ depending on several factors, including pricing strategies, regulatory approvals, and overall market conditions. The FlexVent’s success hinges on the ability to offer a compelling value proposition in terms of performance, price, and user experience.

Manufacturing and Supply Chain Considerations

The Belkin-University of Illinois FlexVent partnership presents exciting possibilities for ventilator production, but also significant logistical challenges. Successfully navigating these hurdles will be crucial for rapid deployment and global access to this vital medical equipment. Optimizing manufacturing strategies and proactively addressing supply chain vulnerabilities are paramount to ensure the timely and effective response to future crises.

The Belkin ventilator partnership with the FDA and the University of Illinois Flexvent project is fascinating. It’s a real-world application of innovative engineering, and I’ve been digging into the details. Speaking of fascinating projects, have you seen the Steven Soderbergh Mosaic HBO app? steven soderbergh mosaic hbo app download is definitely something to check out if you’re into digital art.

Ultimately, these projects, from medical breakthroughs to artistic endeavors, highlight the potential of collaboration and ingenuity, much like the potential of Belkin’s ventilator partnership.

Potential Manufacturing Strategies

Belkin’s expertise in consumer electronics manufacturing offers valuable insights into scalable production methods. Leveraging their existing infrastructure and supply chain networks could accelerate the production of the FlexVent, particularly in high-volume scenarios. A key strategy will be to explore modular design principles. This allows for standardized components, facilitating easier assembly and reducing production time. Furthermore, the partnership could consider establishing strategic manufacturing partnerships with existing ventilator manufacturers or companies specializing in medical device production.

This approach would allow for leveraging existing expertise and infrastructure, reducing the need for entirely new facilities and equipment.

Supply Chain Issues and Solutions

Identifying and mitigating potential supply chain disruptions is critical for ventilator production. Material shortages, particularly for crucial components like specialized plastics and electronic components, could severely impact production timelines. Building diverse supplier networks is a key solution. This means identifying multiple suppliers for critical materials, and creating contingency plans to quickly switch suppliers in case of disruptions.

Another crucial aspect is proactive inventory management. Maintaining adequate stock levels of key components, through strategic partnerships with suppliers and robust forecasting models, will ensure minimal delays and maintain production momentum.

Impact on Global Supply Chain

The partnership’s impact on the global ventilator supply chain will be significant. By developing a robust and reliable production model, the Belkin-University of Illinois collaboration can contribute to increased global ventilator capacity. This enhanced production capability could have a positive impact on regions with limited access to ventilators, especially during global health crises. The experience gained from the FlexVent production could be used to develop a more resilient and responsive global supply chain for medical devices in the future.

Manufacturing Process Comparison

| Manufacturing Process | Implications | Suitability for FlexVent |

|---|---|---|

| Traditional Assembly Line | Efficient for high-volume production, but inflexible to design changes. | Potentially suitable for high-volume production phases, but may not be ideal for initial production runs. |

| Modular Design | Allows for customization and quicker adjustments to design requirements, promoting flexibility. | Highly suitable due to the potential for quick adaptation and standardization of components. |

| 3D Printing | Enables rapid prototyping and production of custom parts, but limited in volume. | Useful for initial prototyping and small-scale production, but not for large-scale manufacturing. |

| Collaborative Manufacturing | Leveraging existing infrastructure and expertise of multiple partners, optimizing resource utilization. | Potentially beneficial for accelerating production and ensuring access to specialized expertise. |

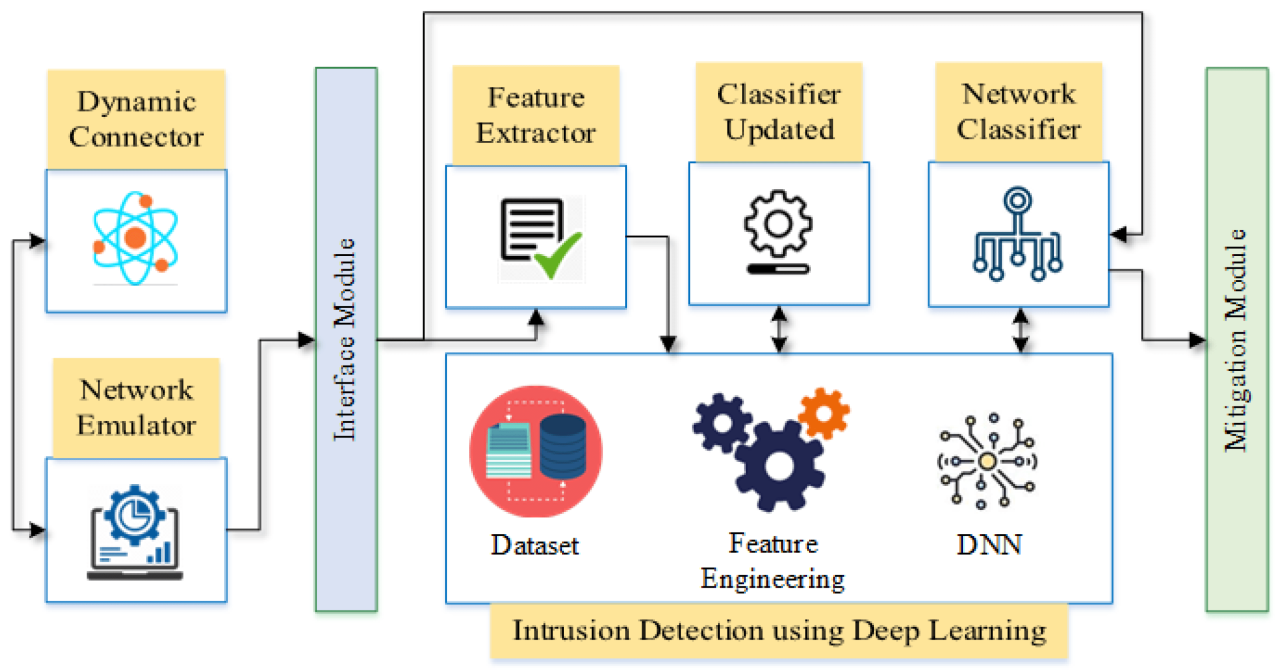

Research and Development Initiatives

This partnership between Belkin, the University of Illinois FlexVent team, and the FDA presents a unique opportunity for accelerated research and development in ventilator technology. The collaboration leverages Belkin’s expertise in consumer electronics and manufacturing with the University’s advanced engineering capabilities and the FDA’s regulatory oversight. This synergy will likely drive innovation, resulting in more efficient, affordable, and potentially life-saving ventilators.

Potential Research and Development Activities

The partnership will likely focus on several key research areas. These include optimizing the FlexVent design for broader application, enhancing its user-friendliness, and exploring novel materials for improved durability and cost-effectiveness. Additionally, research into remote monitoring capabilities and integration with existing healthcare IT systems will be vital for improving patient care. These efforts will also aim to reduce manufacturing costs and improve scalability to meet potential global demand.

Innovation in Ventilator Technology

The collaboration promises to spur innovation in ventilator technology by combining diverse perspectives. Belkin’s consumer electronics background will likely contribute to the design of user-friendly interfaces and compact, portable designs. The University of Illinois FlexVent team’s engineering expertise will ensure high performance and reliability. The FDA’s input will guarantee compliance with stringent safety standards, creating a holistic approach to ventilator development.

Future Research Directions

Future research will likely explore integrating advanced sensor technologies for real-time patient monitoring. The possibility of incorporating artificial intelligence (AI) for predictive maintenance and improved diagnostics will also be explored. Furthermore, the research will focus on developing methods to customize ventilators to specific patient needs, potentially through 3D printing or personalized design features. The partnership will also likely explore the integration of telehealth platforms for remote patient care and support.

Potential Research Outcomes and Timelines, Belkin ventilator partnership fda university of illinois flexvent

| Research Outcome | Timeline (Estimated) |

|---|---|

| Improved user interface and compact design | 18-24 months |

| Enhanced remote monitoring capabilities | 24-36 months |

| Integration with existing healthcare IT systems | 36-48 months |

| Cost-effective manufacturing processes | 18-30 months |

| AI-driven predictive maintenance and diagnostics | 36-48 months |

| Personalized ventilator designs | 48-60 months |

Note: These timelines are estimates and subject to change based on project progress and unforeseen circumstances.

Ethical and Societal Implications

The Belkin-University of Illinois FlexVent partnership, while promising advancements in ventilator technology, necessitates a careful examination of its ethical and societal implications. This collaboration has the potential to significantly impact healthcare access and affordability, but it also raises crucial questions about equitable distribution, cost-effectiveness, and potential unintended consequences. A comprehensive understanding of these implications is paramount for responsible development and implementation of this innovative technology.

Potential Ethical Implications of Belkin’s Expertise

Belkin’s expertise in consumer electronics, coupled with the complex medical requirements of ventilators, presents a unique set of ethical considerations. The transition from consumer product design to life-sustaining medical equipment demands careful attention to quality control, safety protocols, and maintenance procedures. Ensuring consistent, reliable operation of the FlexVent across diverse populations and healthcare settings is critical to mitigate potential harm.

Addressing potential disparities in access and affordability is also essential for ethical considerations.

Societal Impact on Healthcare Access and Affordability

This collaboration holds the potential to revolutionize healthcare access by making advanced ventilation technology more accessible and potentially less expensive. However, the high upfront costs of development and potential manufacturing costs could pose a significant barrier to lower-income populations. The need for adequate training and maintenance support for healthcare providers using the FlexVent is crucial to ensuring consistent quality of care.

Moreover, the potential for widespread adoption could significantly impact the demand for existing ventilator technologies, impacting existing manufacturers and potentially causing a disruption in the market.

Social Benefits and Drawbacks

This collaboration promises several potential social benefits, including increased access to life-sustaining care in underserved communities, potentially reducing mortality rates associated with respiratory failure, and improving the quality of life for those requiring respiratory support. However, potential drawbacks include the possibility of exacerbating existing healthcare disparities if the technology is not priced competitively or if access is not equitably distributed.

The social cost of potentially compromising the quality of care due to inadequate training or maintenance support must also be carefully considered.

Comparison of Ethical Considerations Across Ventilator Technologies

| Ventilator Technology | Ethical Considerations |

|---|---|

| Traditional Mechanical Ventilators | High initial cost, limited accessibility in low-resource settings, potential for dependence, ongoing maintenance requirements. |

| Modular Ventilators | Increased modularity and adaptability, but potential complexity in use, need for specialized training, possible increase in cost depending on the modular configuration. |

| FlexVent (Belkin Partnership) | Potential for lower cost, increased accessibility, need for rigorous quality control and safety standards, potential for widespread adoption and its impact on existing market. |

This table highlights the varying ethical considerations across different ventilator technologies, emphasizing the unique challenges and opportunities presented by the Belkin partnership’s FlexVent. The critical need for transparent pricing models, equitable distribution strategies, and robust training programs for healthcare professionals must be addressed for the responsible implementation of this innovative technology.

End of Discussion: Belkin Ventilator Partnership Fda University Of Illinois Flexvent

The Belkin ventilator partnership fda university of illinois flexvent signifies a promising future for innovative respiratory care. By combining Belkin’s design prowess with the University of Illinois’s technological advancement, this collaboration has the potential to revolutionize the market and improve patient outcomes. However, navigating the complex FDA regulatory landscape will be crucial for successful market entry. The future of ventilators, and ultimately patient care, may very well hinge on the success of this unique partnership.