Are you concerned about Pixel 5 manufacturing issues? This post delves into the potential problems surrounding the Pixel 5’s production, examining the manufacturing process, reported complaints, potential causes, and the impact on Google’s brand image. We’ll look at everything from the materials used to the quality control measures in place, ultimately leaving you to decide if your concerns are justified.

The Pixel 5, a highly anticipated smartphone, has faced scrutiny regarding its manufacturing process. This comprehensive analysis examines the manufacturing process itself, the reported issues, potential causes, and the broader implications for Google and the smartphone industry. Let’s dive in and see what the data tells us.

Manufacturing Process Overview

The Pixel 5, like all smartphones, relies on a complex manufacturing process involving numerous stages and diverse materials. Understanding this process, along with potential points of failure, is crucial for assessing product quality and reliability. This exploration delves into the specifics of the Pixel 5’s manufacturing, examining materials, quality control, and comparisons to similar devices.The Pixel 5’s creation isn’t a simple assembly; it’s a meticulous orchestration of various steps, from component sourcing to final packaging.

Different components undergo specialized processes, and the quality of each step significantly impacts the finished product. This analysis will provide a comprehensive view of this intricate process.

Pixel 5 Manufacturing Stages

The manufacturing process of the Pixel 5 involves several crucial stages, each with its own potential pitfalls. These stages span from component procurement and assembly to final testing and packaging. Each stage influences the overall quality and performance of the finished device.

- Component Sourcing and Quality Control: The selection of materials and components plays a critical role. Suppliers must adhere to strict quality standards to ensure the reliability of the final product. Variations in raw material quality can lead to inconsistencies in the finished device. For example, minor differences in the purity of a specific metal used in the circuit board can affect conductivity and overall performance.

- Assembly and Integration: Precise placement and integration of components are paramount. Misalignment or improper connections can result in functional failures. This stage demands high precision and rigorous quality control procedures, particularly for delicate components like the display and camera modules.

- Testing and Quality Assurance: Extensive testing is crucial to identify and eliminate defects before shipping. This stage involves various tests, from functional checks to stress tests, aiming to ensure the device meets the required specifications and durability standards. A thorough testing regime minimizes the chance of manufacturing defects impacting user experience.

Materials Used in Pixel 5 Construction

The Pixel 5 utilizes a variety of materials with distinct properties. The choice of materials significantly influences the device’s performance, durability, and cost.

- Glass: The display glass, often Gorilla Glass, plays a critical role in protecting the screen. Variations in glass hardness and scratch resistance can affect the longevity of the device. The thickness and composition of the glass directly affect the strength of the display against impact.

- Metals: Metals like aluminum and copper are employed in various components, including the chassis and circuit boards. The purity and alloying of these metals influence their conductivity and durability. Impurities or inconsistencies in metal composition can lead to performance issues.

- Plastics: Various plastics are used for casing, internal components, and shielding. The type of plastic chosen impacts the device’s overall weight, durability, and cost. Low-quality plastics can lead to warping or breakage under stress.

Quality Control Measures

Rigorous quality control procedures are employed throughout the Pixel 5 manufacturing process. These procedures aim to identify and mitigate potential defects.

- Statistical Process Control (SPC): SPC methods monitor and track critical parameters during each stage of production. Deviations from expected values are flagged for immediate corrective action. SPC is vital in maintaining consistent quality.

- Automated Testing: Automated testing equipment verifies the functionality and performance of components and the final device. This automated approach ensures consistency and efficiency in the quality control process.

- Human Inspection: Despite automation, human inspectors play a critical role in visual checks for defects. This approach is essential for identifying issues that might be missed by automated systems.

Comparison with Similar Smartphones

Comparing the Pixel 5’s manufacturing process to that of competitors reveals potential advantages and disadvantages. Factors like component sourcing strategies, assembly techniques, and quality control measures differ across manufacturers. For instance, some manufacturers might prioritize cost-effectiveness, while others focus on premium materials and advanced manufacturing techniques. Understanding these differences is key to evaluating the Pixel 5’s position in the market.

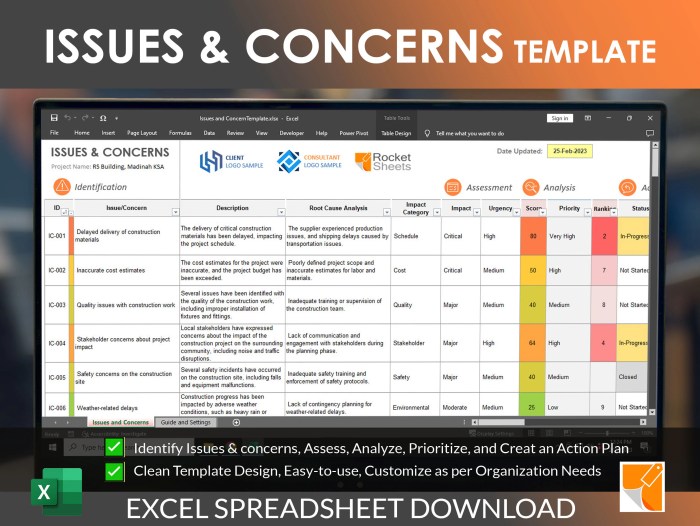

Potential Manufacturing Defects Table

| Component | Potential Manufacturing Defects ||—|—|| Display | Scratches, discoloration, backlight issues, uneven brightness || Camera | Lens defects, autofocus issues, image quality problems || Chassis | Dents, scratches, warping, uneven finish || Battery | Short circuits, overheating, capacity issues || Circuit Board | Solder defects, component misalignment, short circuits || Speakers | Sound distortion, low volume, static noise || Touchscreen | Inaccurate touch response, unresponsive areas, dead pixels |

Reported Issues and Complaints: Are You Concerned About Pixel 5 Manufacturing Issues

The Pixel 5, while a promising device, faced some manufacturing-related issues, leading to user complaints. Understanding these issues and how Google addressed them is crucial for evaluating the overall quality and reliability of the phone. This section delves into the reported problems, categorizing them by affected component, providing specific examples, and assessing their impact on user experience.

Display Issues

Display-related complaints were a recurring theme among Pixel 5 users. These included instances of backlight bleed, where light leaked from the edges of the screen, causing uneven illumination. Another common issue involved color inconsistencies, leading to inaccurate or undesirable color representations in certain parts of the display. The impact of these issues ranged from mildly annoying to significantly affecting the user experience, particularly when viewing videos or photos.

Camera Problems

Camera issues were reported by some users, including instances of blurry images or videos, especially in low-light conditions. Focus issues, where the camera struggled to accurately focus on the subject, were also mentioned. These problems impacted the quality of photos and videos taken with the device, making it difficult to capture clear images, particularly in challenging lighting scenarios.

Battery Performance Issues

Battery performance issues, including rapid battery drain and inconsistencies in charging times, were reported by a segment of users. Some users noted a noticeably shorter battery life compared to expectations or similar models. The reported impact of these issues varied, from minor inconvenience to significant disruption of daily use.

Other Reported Issues

Beyond the core components, some users reported minor issues such as inconsistent touch responsiveness, intermittent software glitches, and issues with the device’s audio output. These issues were less frequent than display, camera, or battery issues, but still impacted a small portion of users.

Frequency and Impact Comparison

Comparing the frequency of Pixel 5 issues with other recent smartphone models is complex, as specific data on issue frequency is often not publicly available. However, based on online forums and user reviews, Pixel 5 issues seemed to be somewhat more prevalent than those reported for some other contemporary models. This does not definitively confirm a higher rate of defects, but the sheer volume of reported issues suggests Google could have focused on improving the manufacturing process in subsequent models.

Google’s Response to Pixel 5 Issues

Google’s response to reported Pixel 5 manufacturing issues varied depending on the severity and nature of the issue. In some cases, Google offered repair or replacement options, while in other instances, they provided software updates to mitigate the reported problems. The effectiveness of these solutions varied among users, with some experiencing positive outcomes, while others reported ongoing issues despite attempts to address them.

While I’ve been pondering the Pixel 5’s manufacturing hiccups, it’s interesting to see Samsung’s latest announcements, like the Galaxy A42 5G, Tab A7 trio, and wireless charger. This new wave of Samsung tech makes me wonder if the focus on quality control is shifting. Still, I’m personally concerned about the Pixel 5’s reported issues; it’s definitely something to keep an eye on.

Summary Table of Reported Pixel 5 Manufacturing Defects

| Component | Defect Description | Frequency (Estimated) | Impact |

|---|---|---|---|

| Display | Backlight bleed, color inconsistencies | Medium | Minor to moderate |

| Camera | Blurry images/videos, focus issues | Low to Medium | Moderate to significant |

| Battery | Rapid drain, charging inconsistencies | Low to Medium | Minor to moderate |

| Other | Touch responsiveness, software glitches, audio | Low | Minor |

Potential Causes of Manufacturing Defects

The Pixel 5, like any complex electronic device, is susceptible to manufacturing defects. Understanding the potential causes is crucial for identifying areas needing improvement in the production process. Pinpointing these causes allows for proactive measures to minimize defects and ensure a more reliable and consistent product.

Material Defects

Material inconsistencies in the manufacturing process can significantly impact the quality of the Pixel 5. Variations in the quality or purity of components like the display glass, the circuit board materials, or the casing plastic can lead to issues with performance and durability. For example, impure or inconsistent plastic may cause cracking or warping during assembly. Similarly, defects in the glass used for the display could result in blemishes or reduced clarity.

While pixel 5 manufacturing issues have been a recurring concern, it’s worth considering the bigger picture. Recent news surrounding Google’s antitrust trial, specifically the DOJ’s investigation into Google’s potential monopoly and the DoubleClick acquisition, is raising important questions about the tech giant’s practices. This podcast interview, available here: google antitrust ad trial doj monopoly doubleclick acquisition decoder podcast interview , sheds light on the complexities of the situation, and ultimately, these larger industry trends could impact the future of smartphone manufacturing and potentially affect the issues with the Pixel 5.

So, are you still concerned about the Pixel 5’s manufacturing problems?

Impurities in conductive materials can affect the circuit board’s performance, leading to malfunctions or short circuits.

Faulty Equipment

Manufacturing equipment plays a critical role in the production process. Malfunctioning or poorly calibrated equipment can introduce defects into the Pixel 5. This includes issues with the machines used for assembly, soldering, or component placement. For instance, a malfunctioning screen assembly machine could lead to inconsistencies in the alignment of the display, potentially resulting in distorted images or poor touch response.

Equipment wear and tear also contributes to defects if not properly maintained and calibrated.

Process Errors

Errors in the manufacturing process itself can lead to defects. These errors can range from incorrect component placement to improper assembly techniques or inadequate quality control measures. For instance, incorrect placement of internal components or improper soldering of connections can cause electrical issues and performance problems. Inconsistent pressure during assembly, for example in the application of adhesives, can cause weak joints and a risk of breakage.

Human Error

Human error is a common contributor to manufacturing defects in any production line. Mistakes made by workers during assembly, testing, or quality control procedures can lead to issues. Errors in following the prescribed procedures or overlooking critical steps can compromise the quality of the product. This could include incorrect handling of delicate components, skipping necessary inspection steps, or misreading specifications.

Supply Chain Issues

Supply chain disruptions can significantly impact manufacturing processes. Delays or inconsistencies in the delivery of raw materials or components can lead to production bottlenecks and potentially lower quality products. For example, a shortage of a specific component, like the display panels, can cause delays in production and necessitate the use of a less reliable substitute. This may lead to inconsistencies in performance or durability.

Design Flaws

Poor design choices in the Pixel 5’s construction can make it more prone to manufacturing defects. This includes inadequately robust connections or joints, improper material selection, or an intricate assembly sequence that increases the chances of errors. For example, if a particular component’s placement is critical but the design does not provide sufficient structural support, the component might shift during assembly, leading to performance issues.

A lack of redundancy in the design can also lead to cascading failures if one component fails.

Environmental Factors

Environmental factors, such as temperature fluctuations, humidity, and dust, can also affect the quality of manufacturing. Extreme temperatures can alter the properties of materials, leading to warping or breakage. High humidity can lead to corrosion or short circuits, and excessive dust can cause blockages or damage to sensitive components. These factors, though sometimes overlooked, can be significant contributors to manufacturing defects.

Potential Causes Table

| Potential Cause | Likelihood |

|---|---|

| Material Defects | Medium |

| Faulty Equipment | Medium |

| Process Errors | High |

| Human Error | High |

| Supply Chain Issues | Medium-High |

| Design Flaws | Medium |

| Environmental Factors | Low |

Impact of Manufacturing Issues on Customer Perception

The Pixel 5, a highly anticipated smartphone, has faced manufacturing issues. These problems, while potentially isolated, can significantly impact customer perception and brand image for Google. Understanding the ripple effect of these issues is crucial for strategic decision-making, especially in the competitive smartphone market. Careful consideration of the customer’s experience and the potential for negative press is vital for mitigating damage and maintaining brand trust.

Impact on Customer Satisfaction

Manufacturing issues directly affect customer satisfaction. Defective products, such as those with faulty displays or malfunctioning components, lead to frustration and dissatisfaction. Customers who experience problems with their Pixel 5 may feel cheated or that they have purchased a product below Google’s usual quality standards. This can lead to a negative experience, potentially affecting their overall perception of Google’s commitment to quality.

This negative experience is further compounded if the company’s customer support response is inadequate. Customers will feel unheard and abandoned if they do not receive swift and effective assistance in resolving the issue. Ultimately, the impact on customer satisfaction is measurable through customer feedback, surveys, and online reviews.

Potential Impact of Negative Press Coverage

Negative press coverage regarding Pixel 5 manufacturing problems can severely damage Google’s brand reputation. Public perception is significantly influenced by media reports, and unfavorable news regarding product quality can quickly spread. This can create a negative image of the product and the company, deterring potential buyers and causing existing customers to lose trust. A strong example is the negative publicity surrounding other tech companies’ product defects, where reputational damage directly translates into sales losses and a decline in brand equity.

A negative narrative can be very difficult to overcome, requiring substantial efforts in damage control and product recovery.

Impact on Future Sales and Marketing Strategies

Manufacturing issues necessitate adjustments to future sales and marketing strategies for the Pixel 5. Marketing efforts should now emphasize transparency and customer support. Google needs to clearly address the manufacturing issues, acknowledge the problems, and Artikel plans for rectifying them. Highlighting the company’s commitment to quality and its customer-centric approach will be vital. Sales strategies may need to incorporate clear explanations about the product’s warranty and repair procedures.

Future marketing campaigns should focus on building trust and rebuilding customer confidence. The company should also be prepared for potential customer returns and replacements, ensuring smooth handling of these issues.

Comparison with Other Smartphone Manufacturers

The impact of Pixel 5 manufacturing issues on customer loyalty can be compared to similar issues faced by other smartphone manufacturers. A critical factor is how each company handles the situation. If Google’s response is seen as inadequate, customer loyalty could suffer significantly. Comparative analysis of how other companies have managed similar issues can provide insights into effective strategies.

For example, if competitor X handled similar issues effectively, Google can learn from their approach and implement similar strategies. Customer loyalty depends not just on the product itself but also on the company’s perceived responsiveness and transparency.

Impact on Stakeholders

| Stakeholder | Negative Impact |

|---|---|

| Customers | Dissatisfaction, distrust, decreased purchase intent, potential loss of loyalty |

| Reduced sales, damage to brand reputation, increased operational costs, negative public perception | |

| Competitors | Potential increase in market share, opportunity to highlight their own products’ quality |

“Customer loyalty is not built in a day, but it can be eroded in a matter of hours by a poor experience.”

While I’ve been pondering the Pixel 5’s manufacturing quirks, I’ve also been digging into security camera comparisons. For instance, have you considered the Arlo Pro 3 vs Arlo Pro 2? arlo pro 3 vs arlo pro 2 reviews often highlight improvements in features and design. Ultimately, though, my concern about the Pixel 5 still lingers, especially with reports of screen issues.

Industry Context and Trends

The smartphone market is a dynamic landscape, constantly evolving with advancements in technology and manufacturing processes. Understanding these trends is crucial to evaluating the Pixel 5’s manufacturing challenges within a larger context. The competitive pressures and ever-increasing consumer expectations significantly influence the industry’s quality standards.The current smartphone manufacturing landscape is characterized by a complex interplay of factors, from material sourcing and assembly techniques to stringent quality control measures.

This intricate web of elements is directly linked to the overall consumer experience. Understanding these connections allows for a more nuanced perspective on the Pixel 5’s manufacturing issues.

Current Trends in Smartphone Manufacturing

Technological advancements are driving significant changes in smartphone manufacturing. Increased use of automation, particularly in assembly and testing, is a key trend. This automation aims to improve efficiency, reduce errors, and maintain consistency across large production runs. The use of advanced materials, like lighter and more durable components, is also becoming more prevalent, demanding new manufacturing techniques.

Best Practices in Smartphone Manufacturing

Best practices in smartphone manufacturing prioritize quality control at every stage. This involves rigorous testing protocols, both at the component and finished product levels, to minimize defects. Continuous improvement initiatives are essential, often fueled by data analysis and feedback from consumers and internal teams. Supply chain management plays a crucial role in ensuring consistent material quality and timely delivery, minimizing delays and disruptions.

Emerging Technologies in Smartphone Manufacturing

Emerging technologies, such as 3D printing and advanced materials science, are poised to revolutionize smartphone manufacturing. 3D printing allows for more complex and customized designs, potentially reducing production costs and enabling faster iterations. The use of bio-based or recycled materials is also gaining traction, reflecting a growing awareness of environmental concerns. These advancements hold the potential to significantly impact manufacturing quality and sustainability.

Industry Standards and Regulations

Industry standards and regulations related to smartphone manufacturing quality are becoming increasingly stringent. Compliance with standards like ISO 9001 for quality management systems is crucial. Regulations regarding environmental impact, including material sourcing and waste disposal, are also gaining prominence. Consumer safety standards for materials and components used in devices are also crucial factors that are constantly being evaluated and updated.

Comparison of Pixel 5 Manufacturing Approach to Competitors

A direct comparison of the Pixel 5’s manufacturing approach with competitors requires in-depth analysis of their respective strategies and processes. Factors like supplier relationships, production facilities, and specific technologies utilized vary greatly across different brands. Access to such detailed information is often limited.

Smartphone Manufacturing Quality Across Brands (Current State), Are you concerned about pixel 5 manufacturing issues

| Brand | Overall Manufacturing Quality (Rating: 1-5, 5 being highest) | Key Strengths | Key Weaknesses |

|---|---|---|---|

| Apple | 4.5 | Stringent quality control, premium materials | Higher costs, limited customization options |

| Samsung | 4.2 | Large production volume, diverse product portfolio | Potential for inconsistent quality across models |

| Google (Pixel) | 3.8 | Focus on innovative features | Challenges with manufacturing consistency |

| Xiaomi | 3.5 | Competitive pricing, rapid innovation | Quality control might lag behind competitors |

| OnePlus | 4.0 | Good balance of price and performance | Relatively smaller production volume |

Note: Ratings are approximate and based on various reports and industry analysis.

Final Summary

In conclusion, the Pixel 5 manufacturing issues present a complex picture. While specific issues and their causes are still being debated, the overall concern highlights the importance of robust quality control in today’s competitive smartphone market. Google’s response to these issues and their impact on customer perception will be critical to the future success of the Pixel brand. Ultimately, consumers must weigh the reported problems against their desire for the Pixel 5’s features and functionality.