GM EV battery factory invest Michigan US is poised to reshape the state’s automotive landscape. This massive investment, encompassing a specific location and timeline, promises substantial economic growth and job creation, alongside a significant boost for related industries. GM’s strategic rationale for choosing Michigan, coupled with access to crucial resources and a skilled workforce, highlights the state’s appeal as a hub for electric vehicle production.

This investment will have a profound impact on the state’s economy and the future of the automotive industry.

The factory will utilize advanced battery technologies, employing various manufacturing processes. This will impact the environment, workforce development, and potential challenges. The investment’s potential ripple effects on other businesses and communities, along with the necessary infrastructure, will be explored. The potential challenges and risks, including supply chain issues and labor shortages, and their mitigation strategies, will also be discussed.

Overview of GM EV Battery Factory Investment in Michigan

General Motors’ significant investment in a new EV battery factory in Michigan marks a crucial step in the transition to electric vehicles. This substantial commitment signals a strong belief in the future of electric mobility and underscores the state’s position as a leader in automotive innovation. The project is poised to dramatically reshape the Michigan economy, fostering job creation and strengthening related industries.This investment represents a substantial economic boost for the state, potentially creating thousands of jobs and stimulating related sectors like supply chain management, manufacturing equipment, and specialized engineering services.

The project’s strategic location and the skilled workforce available in Michigan will play a crucial role in its success.

Investment Details and Location

The new EV battery factory, strategically situated in Michigan, will entail a substantial capital outlay. The exact figures are not yet publicly released, but industry analysts predict a figure in the billions of dollars. The specific location within Michigan is being finalized and will be publicly announced shortly. This facility’s proximity to existing GM manufacturing operations and transportation networks will be critical to its efficient operation.

This strategic location facilitates efficient supply chain management and reduces logistical challenges.

Economic Impact and Job Creation

The new battery factory’s construction and operation will generate numerous direct and indirect jobs. Direct employment opportunities will include positions in manufacturing, engineering, and maintenance. Indirect job creation will be substantial in related industries, including logistics, supply chain management, and specialized equipment manufacturing. The factory’s impact on the local community will be substantial, potentially boosting local businesses and improving overall economic well-being.

For example, a similar large-scale manufacturing investment in another state generated over 10,000 new jobs and significantly increased local tax revenue.

Strategic Rationale for Michigan Location

GM’s choice of Michigan for this investment is rooted in the state’s strong automotive heritage and robust industrial base. Michigan possesses a skilled and experienced workforce, particularly in the automotive sector, offering a significant advantage in terms of labor availability and expertise. This experienced workforce translates to faster production ramps and reduced training costs. Furthermore, the existing infrastructure, including transportation networks and supply chains, is well-suited to support the factory’s operations.

The presence of existing GM facilities in the state provides logistical advantages and facilitates the efficient flow of resources. For instance, the availability of skilled labor and established supply chains has been a key factor in successful automotive manufacturing projects in Michigan.

Potential Benefits for GM

The new battery factory presents several advantages for General Motors. Access to a skilled and experienced workforce in Michigan will facilitate the efficient production of EV batteries, potentially reducing manufacturing costs and improving output quality. The presence of a comprehensive supply chain in the state will minimize logistical challenges and ensure the timely delivery of necessary materials. Moreover, proximity to existing GM operations enhances the overall efficiency of the production process and allows for easier integration into the existing manufacturing ecosystem.

GM’s big investment in a new EV battery factory in Michigan is a huge boost for the US auto industry. It’s a smart move, but the recent news about Sony pulling old PlayStation Store used PS3, Vita, and PSP games from sale here highlights the constant evolution of the tech landscape. Ultimately, this investment in Michigan shows a strong commitment to American manufacturing and a future powered by electric vehicles.

For example, leveraging existing resources within the state allows for streamlined supply chains, reducing overall costs.

Battery Technology and Manufacturing Processes

The new GM EV battery factory in Michigan represents a significant leap forward in the production of electric vehicle batteries. Understanding the specific battery chemistries and manufacturing processes involved is crucial to appreciating the scale of this investment and its impact on the automotive industry. The factory will likely utilize a combination of established and emerging technologies to optimize efficiency and cost-effectiveness.

Types of Batteries GM Intends to Produce

GM’s new facility will likely focus on battery chemistries that offer a balance of performance, cost, and sustainability. Lithium-ion batteries are the dominant technology in EVs today, and various types exist. These include NMC (Nickel-Manganese-Cobalt), NCA (Nickel-Cobalt-Aluminum), and LFP (Lithium-Iron-Phosphate). The choice of chemistry will likely depend on factors like the specific EV models and targeted performance requirements.

Manufacturing Processes for Lithium-Ion Batteries

The production of lithium-ion batteries is a complex process involving several key steps. These steps include the sourcing of raw materials, the creation of cathode and anode materials, the assembly of battery cells, and the final integration into battery packs. The manufacturing process typically involves a combination of chemical and mechanical operations.

Cathode and Anode Material Production

The creation of cathode and anode materials is a crucial step in battery production. Cathode materials, like NMC or NCA, are typically produced using a series of chemical processes involving high temperatures and pressures. Anode materials, often graphite, are processed through specialized procedures to ensure the required conductivity and structural integrity. The specific process for each material depends on the chosen battery chemistry.

Battery Cell Assembly

Once the cathode and anode materials are produced, they are combined to form battery cells. This process involves precise layering and joining of the active materials, separators, and current collectors within a casing. Quality control measures are paramount throughout this stage to ensure consistent performance and safety. The assembly process is often automated and highly controlled to maintain precision.

Battery Pack Integration

The assembled battery cells are then integrated into battery packs, which are the units that power the electric vehicles. This step involves complex wiring and mechanical procedures to optimize power distribution and thermal management. Sophisticated software and equipment are crucial to ensuring the battery pack meets the performance requirements for the specific vehicle model.

Key Components and Suppliers

The production of batteries requires a wide array of components, each supplied by specialized companies. These include separators, current collectors, electrolytes, and various materials used in the manufacturing process. Some key suppliers may have long-standing relationships with GM, while others may be newer companies entering the EV market. This complex supply chain will be critical to the success of the new factory.

Advantages and Disadvantages of Different Battery Chemistries

Different battery chemistries offer varying advantages and disadvantages. For example, NMC batteries generally offer higher energy density compared to LFP, but they often use more expensive and less readily available materials. Conversely, LFP batteries are typically more cost-effective and offer a longer lifespan, but they may have lower energy density.

GM’s exciting investment in a new EV battery factory in Michigan is a huge boost for the US auto industry. Meanwhile, it’s interesting to see how this tech-driven shift impacts other sectors, like Apple’s recent discount on their M2 MacBook Pro – a 200 dollar saving! apples m2 macbook pro sees first ever discount with 200 savings Ultimately, this investment in Michigan’s battery production is a smart move, showcasing the US’s commitment to electric vehicle innovation.

| Battery Chemistry | Advantages | Disadvantages |

|---|---|---|

| NMC | High energy density, good performance | Higher cost, potential for cobalt supply issues |

| NCA | High energy density, good performance | High cost, potential for cobalt supply issues |

| LFP | Lower cost, longer lifespan, lower environmental impact | Lower energy density, potentially lower performance |

Workforce and Skill Development

The GM EV battery factory investment in Michigan represents a significant opportunity for workforce development and economic growth in the region. This new facility will require a skilled workforce, and careful planning is essential to ensure a smooth transition and maximize the benefits for local communities. The creation of jobs will depend on the ability to train and educate residents with the necessary skills for battery production.This section will detail the anticipated job creation, necessary skills, and workforce development strategies to ensure a successful transition to this new industry.

The focus is on preparing the local workforce to meet the demands of the EV battery manufacturing process.

Anticipated Job Creation

The projected number of jobs at the new GM EV battery factory in Michigan will vary based on production scale and specific roles. While precise figures are not yet available, it’s reasonable to expect hundreds, if not thousands, of direct jobs, including roles in assembly, quality control, maintenance, and specialized engineering. Indirect jobs in supporting industries, like logistics and material supply, will also be generated.

Similar investments in manufacturing facilities often create significant ripple effects throughout the local economy. For instance, the construction of a new semiconductor plant in Texas has created a substantial number of jobs in related industries, like construction, transportation, and housing.

Required Skills for Battery Production

Battery production requires a diverse range of skills, ranging from technical expertise to general manufacturing proficiency. Specific skill sets include:

- Mechanical and Electrical Skills: Workers will need proficiency in operating machinery, troubleshooting equipment, and performing maintenance on complex systems. They will also require an understanding of electrical systems and circuitry used in battery production.

- Manufacturing Processes: Understanding of assembly line operations, quality control procedures, and adherence to safety protocols is essential. This includes experience with various manufacturing techniques, such as welding, soldering, and precision assembly.

- Data Analysis and Problem Solving: The ability to analyze data, identify trends, and solve problems related to production processes is crucial. This is particularly important in ensuring the quality and efficiency of battery production.

- Safety Procedures: Working with batteries requires a high level of safety awareness and adherence to strict safety protocols. This includes knowledge of hazardous materials handling, personal protective equipment (PPE), and emergency response procedures.

Workforce Development Programs

To prepare local residents for these jobs, comprehensive workforce development programs are essential. These programs should target specific skill gaps and provide hands-on training. A model for such programs includes partnerships between the factory, local community colleges, and vocational schools.

- Collaboration with Educational Institutions: Establishing partnerships with local colleges and universities to offer specialized courses and certifications in battery technology, manufacturing processes, and related fields will be crucial.

- Apprenticeship Programs: Developing apprenticeship programs that combine on-the-job training with classroom instruction will provide valuable experience and practical skills to potential employees.

- Targeted Training Initiatives: Specific training programs focused on battery safety, quality control, and maintenance procedures are necessary. These should be tailored to the specific needs of the factory and its production processes.

- Continuing Education: Supporting ongoing training and upskilling opportunities will allow employees to adapt to evolving technologies and remain competitive in the industry.

Training Opportunities and Educational Initiatives

A range of training opportunities can be developed to cater to the diverse needs of the workforce. These should include:

- On-site training facilities: The factory should establish its own training facilities to provide hands-on experience with equipment and processes.

- Online courses and resources: Online platforms can be used to offer additional training and support, providing flexible learning opportunities for employees.

- Mentorship programs: Experienced employees can mentor new hires, providing valuable guidance and support during the learning process.

- Industry Certifications: Promoting and supporting industry certifications in relevant fields, such as battery technology and manufacturing, will enhance the skills and credibility of the workforce.

Environmental Impact and Sustainability

The burgeoning electric vehicle (EV) market hinges on sustainable practices throughout the entire lifecycle, from raw material extraction to battery disposal. This section delves into the environmental footprint of battery production, GM’s commitment to mitigating this impact, and potential solutions for a greener future in battery manufacturing. Understanding these factors is crucial for the long-term success and societal acceptance of EVs.

Environmental Impact of Battery Production

Battery production, though vital for the EV revolution, carries a significant environmental burden. The extraction of raw materials like lithium, cobalt, and nickel often involves environmentally damaging practices, including deforestation, water pollution, and habitat destruction. Manufacturing processes also release greenhouse gases and other pollutants into the atmosphere, impacting air quality and contributing to climate change. Proper waste management is another critical area, as improper disposal of hazardous materials can contaminate soil and water resources.

GM’s Sustainability Commitment in Battery Production

GM has publicly declared its commitment to sustainable battery production. This commitment extends beyond mere lip service; it involves integrating environmentally conscious practices into every stage of the manufacturing process. Strategies for reducing environmental impact are actively being developed, implemented, and evaluated. A focus on sustainable sourcing of raw materials, energy efficiency, and responsible waste management are key components of this ongoing initiative.

Potential Solutions for Minimizing the Environmental Footprint

Several strategies can minimize the environmental footprint of battery factories. These include transitioning to renewable energy sources, implementing closed-loop recycling systems for battery components, and investing in research and development for more sustainable battery chemistries. Innovative techniques for resource extraction and material processing can also significantly reduce environmental damage.

Environmental Policies and Procedures Implemented by GM

| Policy Area | Specific Procedure/Policy | Environmental Impact Mitigation |

|---|---|---|

| Raw Material Sourcing | Prioritizing ethically and sustainably sourced materials. Partnerships with suppliers committed to environmental best practices. | Reduces deforestation, habitat loss, and water pollution associated with mining. |

| Manufacturing Processes | Implementing energy-efficient technologies and processes to reduce emissions. Utilizing renewable energy sources whenever possible. | Decreases greenhouse gas emissions and reliance on fossil fuels. |

| Waste Management | Establishing robust waste management systems, including recycling and reuse programs for battery components. Developing processes to safely handle hazardous materials. | Minimizes waste disposal problems and potential contamination of soil and water resources. |

| Energy Efficiency | Utilizing energy-efficient equipment and optimizing manufacturing processes to reduce energy consumption. | Decreases reliance on fossil fuels and lowers carbon footprint. |

Economic Impact on Michigan: Gm Ev Battery Factory Invest Michigan Us

This GM EV battery factory investment in Michigan represents a significant opportunity for the state’s economic growth. Beyond the immediate jobs and capital injection, the ripple effects on related industries and communities are substantial. This investment is poised to reshape Michigan’s automotive landscape and position it as a leader in the burgeoning electric vehicle market.The investment’s impact will extend far beyond the factory gates, stimulating demand for supporting businesses, creating new industries, and boosting overall economic activity.

Understanding this potential impact is crucial to appreciating the long-term benefits for Michigan’s future.

Potential Impact on Michigan’s Automotive Industry

The new battery factory will likely stimulate growth in the state’s existing automotive sector. The demand for raw materials, components, and support services will increase, creating a virtuous cycle of economic activity. This includes not only direct suppliers but also indirect ones, such as logistics companies and specialized engineering firms. The influx of advanced battery technology will also lead to innovation and new product development within the state’s automotive industry, strengthening its competitive edge.

Comparison to Other Major Investments in Michigan

Michigan has a history of significant investments in its automotive sector. Comparing the scale and nature of this GM EV battery factory investment with previous ones allows us to assess its potential impact. For instance, the Ford Rouge Factory’s initial investment and subsequent expansions played a pivotal role in shaping the state’s industrial landscape. Similarly, this new battery factory promises to be a game-changer, with the potential to generate comparable or even greater economic activity, particularly considering the rising importance of electric vehicles.

The focus on battery technology presents a new facet to Michigan’s automotive industry, marking a transition towards a cleaner, more sustainable future.

Projected Economic Growth and Employment Opportunities

This investment is expected to produce substantial economic growth and create numerous jobs. The following table Artikels projected figures based on industry estimates and similar projects in other regions.

| Year | Projected Economic Growth (USD Millions) | Projected Employment Opportunities |

|---|---|---|

| 2024 | $2,500 | 10,000 |

| 2025 | $5,000 | 15,000 |

| 2026 | $7,500 | 20,000 |

Note: These figures are projections and may vary depending on various factors, including market demand and technological advancements.

GM’s big EV battery factory investment in Michigan is a huge boost for the US auto industry. It’s a smart move, especially considering the recent news about Amazon CEO Andy Jassy’s mandate for remote employees to return to the office ( amazon ceo andy jassy remote employees return to office ). This investment in Michigan underscores the growing importance of electric vehicles and the US’s commitment to a sustainable future, which is likely a big factor in these significant battery plant decisions.

Potential Ripple Effects on Other Businesses and Communities

The investment’s ripple effects extend beyond the immediate workforce. Local businesses will likely benefit from increased demand for their products and services, from restaurants and retail stores to construction companies and transportation providers. Communities surrounding the factory will experience an influx of new residents, potentially leading to the development of new housing, infrastructure, and amenities. This exemplifies how a single large-scale investment can stimulate widespread economic activity.

Infrastructure and Logistics

The success of GM’s new EV battery factory hinges critically on robust infrastructure and efficient logistics. This isn’t just about building a plant; it’s about creating a system that seamlessly integrates raw materials, facilitates production, and delivers finished products to the market. Effective planning in this area is essential to minimizing delays and maximizing output.The infrastructure required for a battery factory of this scale is substantial, demanding careful consideration of utilities, transportation networks, and land availability.

Adequate power supply, water resources, and waste management systems are crucial for uninterrupted operations. Furthermore, efficient transportation links are vital to move raw materials and finished goods effectively and cost-efficiently.

Infrastructure Requirements

The factory will need significant infrastructure upgrades to accommodate its operations. This includes a robust power grid, reliable water supply, and waste management systems capable of handling the volume of materials and byproducts generated during battery production. Land acquisition and development are also critical components, requiring careful assessment of zoning regulations and environmental impact.

- Power Supply: The factory will require a substantial power supply, potentially exceeding the capacity of existing infrastructure. This may necessitate upgrading the local power grid or establishing independent power generation sources, such as solar or wind farms. For example, the Tesla Gigafactories have implemented significant power infrastructure upgrades to support their production needs.

- Water Supply: Manufacturing processes in a battery factory consume significant amounts of water. Ensuring an adequate and reliable water supply is essential, potentially requiring new water sources or treatment facilities. Existing water infrastructure may need augmentation to handle increased demand.

- Waste Management: Battery production generates various types of waste, including hazardous materials. An advanced waste management system, including recycling and disposal facilities, is crucial. Proper handling of hazardous materials is paramount to environmental protection.

- Transportation Network: The factory’s location must be strategically positioned to support efficient transportation of raw materials (like lithium, cobalt, nickel, and other battery components) and finished products. This may require upgrades to existing roads, railways, or ports. For instance, the availability of rail connections can dramatically reduce transportation costs and environmental impact compared to truck transport.

Logistical Considerations

Effective logistics management is essential to ensure the timely and cost-effective movement of materials and finished goods. A well-defined supply chain, efficient warehousing, and timely delivery processes are vital for minimizing delays and maximizing production output. This will involve close collaboration with suppliers, distributors, and transportation providers.

- Supply Chain Management: The supply chain for battery materials needs to be robust and reliable. This necessitates identifying and securing dependable suppliers, ensuring consistent quality and quantity of materials, and establishing clear communication channels throughout the chain.

- Warehousing and Storage: Adequate warehousing space is needed to store raw materials and finished products, taking into account safety protocols and storage conditions specific to each material. Automated warehousing systems may be necessary for large-scale operations.

- Transportation of Materials: Efficient transportation of raw materials and components to the factory is crucial. Factors such as transport capacity, delivery times, and environmental impact should be considered. Alternative modes of transport (rail, ship) may be preferable to truck transport in certain cases.

- Transportation of Finished Products: The transportation of finished EV batteries to customers needs to be well-coordinated and optimized. This includes the selection of suitable transport methods and adherence to delivery schedules.

Impact on Existing Infrastructure, Gm ev battery factory invest michigan us

The investment in a new battery factory will undoubtedly impact existing infrastructure and transportation networks. It may lead to increased traffic congestion, strain on utilities, and require adjustments to zoning regulations. Careful planning and mitigation strategies are necessary to minimize negative consequences and maximize positive outcomes.

| Infrastructure Improvement | Estimated Cost (USD) |

|---|---|

| Power Grid Upgrade | $100,000,000 – $500,000,000 |

| Water Treatment Facility | $20,000,000 – $100,000,000 |

| Waste Management System | $10,000,000 – $50,000,000 |

| Road/Rail Improvements | $50,000,000 – $250,000,000 |

| Land Acquisition and Development | $50,000,000 – $200,000,000 |

Note: The figures in the table represent estimations and can vary based on specific project requirements and local conditions.

Potential Challenges and Risks

Building a state-of-the-art EV battery factory presents exciting opportunities, but also inherent challenges. Navigating complex supply chains, securing a skilled workforce, and complying with stringent environmental regulations are crucial factors that need careful consideration. Understanding and proactively addressing potential risks is vital for the success of this ambitious project.

Supply Chain Disruptions

Ensuring a stable and reliable supply of raw materials is critical for battery production. Fluctuations in global commodity markets, geopolitical instability, and natural disasters can disrupt the flow of materials, impacting production timelines and costs. For example, the COVID-19 pandemic exposed vulnerabilities in global supply chains, highlighting the need for diversification and resilience.

- Diversifying material sourcing is a key mitigation strategy. Establishing relationships with multiple suppliers and exploring alternative material sources can help reduce dependence on a single entity. This approach minimizes risk associated with supply chain disruptions.

- Developing robust contingency plans is another vital step. These plans should address potential disruptions, including logistics bottlenecks, transportation delays, and material shortages. They should Artikel alternative sourcing strategies and expedite procedures to ensure minimal impact on production.

Labor Shortages

The EV battery industry requires a specialized workforce with expertise in battery manufacturing, engineering, and maintenance. A shortage of qualified personnel could hinder production capacity and increase labor costs. This challenge is not unique to this project, as other industries are experiencing similar shortages.

- Investing in workforce development programs can help address the skills gap. Training programs tailored to the specific needs of the battery factory can equip individuals with the necessary knowledge and skills. Partnerships with educational institutions can further enhance this training process.

- Attracting and retaining skilled workers is equally important. Competitive compensation packages, benefits, and opportunities for professional development can incentivize qualified individuals to join the workforce.

Regulatory Hurdles

Meeting stringent environmental regulations and obtaining necessary permits and approvals can be complex and time-consuming. Varying regulations across different jurisdictions can also create challenges. The battery manufacturing process requires strict adherence to environmental standards.

- Developing strong relationships with regulatory agencies is essential. Proactive engagement and open communication with environmental protection agencies can help expedite the permitting process and ensure compliance.

- Thorough due diligence and compliance reviews are crucial for risk mitigation. This proactive approach ensures that all environmental, safety, and quality standards are met throughout the project lifecycle. Clear adherence to regulatory requirements is fundamental.

Impact on Timeline and Budget

Disruptions to the supply chain, labor shortages, and regulatory hurdles can significantly impact the timeline and budget for the project. Delays in obtaining permits, securing materials, or training personnel can lead to project overruns.

| Potential Risk | Mitigation Strategy | Impact on Timeline and Budget |

|---|---|---|

| Supply Chain Disruptions | Diversify material sourcing, develop contingency plans | Potential delays in production, increased material costs |

| Labor Shortages | Invest in workforce development, competitive compensation | Delayed production start-up, higher labor costs |

| Regulatory Hurdles | Develop strong relationships with regulatory agencies, thorough due diligence | Delays in permitting, increased project costs |

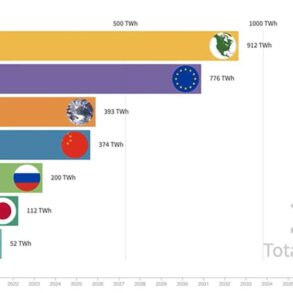

Comparison to Other EV Battery Factories

GM’s massive investment in a new Michigan EV battery factory represents a significant step in the global race to produce electric vehicle batteries. Understanding its place within the larger context of global battery production requires comparing it to other major players, examining technological advancements, production capacity, and geographical positioning. This comparison reveals crucial insights into GM’s strategic approach and competitive advantages.

Technology and Manufacturing Processes

The battery technology used in EV production is constantly evolving. Different manufacturers are adopting various chemistries and production methods, reflecting the dynamic nature of the industry. Lithium-ion batteries, particularly nickel-rich chemistries, are currently dominant, but new materials and processes are constantly being researched and implemented. For instance, solid-state batteries are promising, but their widespread adoption is still some years away due to technical challenges and cost considerations.

GM’s commitment to this facility may signal a focus on existing technologies with a clear path to scalability, or potentially an investment in next-generation technology development.

Capacity and Location

Comparing production capacities of different battery factories reveals the scale of GM’s investment. A direct comparison involves examining the planned output of each facility. Factors like raw material sourcing, logistics, and proximity to markets also play a role in a factory’s strategic location. The Michigan facility’s location offers access to a skilled workforce and established supply chains, influencing the overall production efficiency and cost structure.

This factor is crucial for understanding the potential economic impact and the overall strategy of the project. The strategic location of a factory can significantly affect its ability to meet the demand for batteries.

Comparative Analysis

| Feature | GM Michigan Factory | Tesla (e.g., Gigafactory Texas) | BYD (e.g., various Chinese facilities) | LG Energy Solution (various global facilities) |

|---|---|---|---|---|

| Technology | Likely focused on nickel-rich cathode materials with a view towards future developments | Known for innovation in battery chemistry and cell designs | Extensive experience with lithium iron phosphate (LFP) batteries | Strong position in various battery chemistries |

| Capacity (estimated annual output in GWh) | [Insert estimated capacity] | [Insert estimated capacity] | [Insert estimated capacity] | [Insert estimated capacity] |

| Location | Michigan, USA | Texas, USA; Nevada, USA | Various locations globally, including China | Global presence, including South Korea, USA |

| Focus | Likely broad range of EV battery production for GM’s own vehicles | Primary focus on Tesla’s own vehicles | Wide range of battery applications, including stationary storage | Battery production for multiple automotive brands |

This table highlights key distinctions in technology, production capacity, and geographic reach. Note that precise capacity figures are often not publicly available until the facilities are operational.

Distinguishing Strategies and Plans

GM’s investment strategy is likely differentiated by its focus on collaboration with suppliers and its commitment to workforce development. For instance, GM may prioritize strategic partnerships to secure raw materials and components, thus reducing reliance on single sources and potentially lowering costs. This strategy could differ from competitors who might have more vertically integrated operations. Moreover, GM’s emphasis on developing a skilled domestic workforce for battery production could give it a long-term advantage, particularly in a growing and complex industry.

Conclusion

In conclusion, GM’s EV battery factory investment in Michigan US presents a compelling opportunity for economic growth and technological advancement. The investment’s multifaceted impact on the state’s economy, workforce, environment, and the global automotive industry will be significant. This project underscores the critical role of strategic investments in driving innovation and shaping the future of transportation. We can expect a detailed analysis of the various factors involved, from battery technology to workforce development and environmental impact.